19

BEVEL CROSSCUTTING

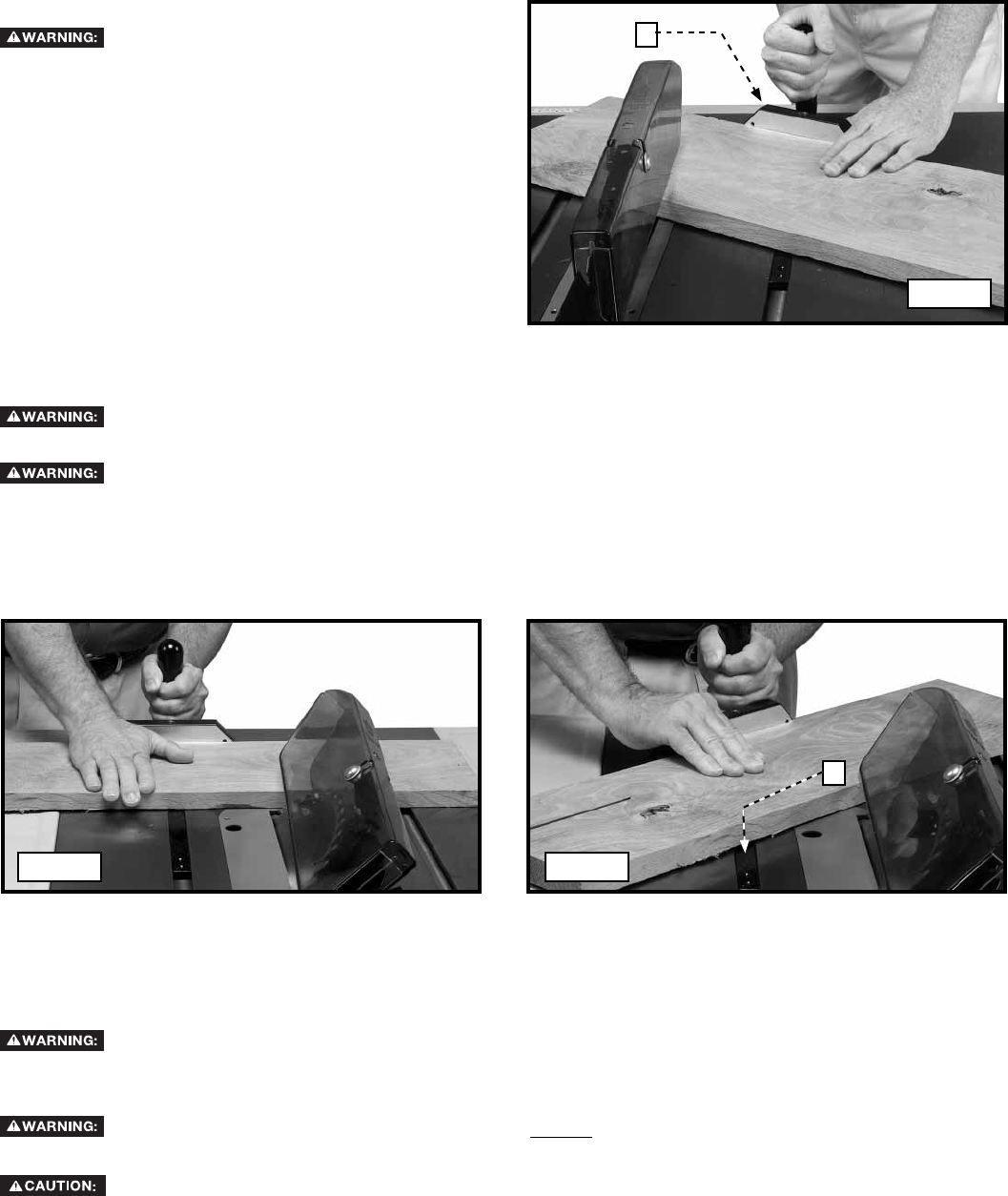

Bevel crosscutting (Fig. 50) is the same as crosscutting except the bevel angle is set to an angle other than 0°.

When possible, use the right miter gauge slot when bevel crosscutting so that the blade tilts away from

the miter gauge and your hands.

Use caution when starting the cut to prevent binding of the guard against the workpiece.

COMPOUND MITERING

Compound Mitering (Fig. 51) is a combination of bevel crosscutting and mitering, where the blade is beveled to an angle other than

0° and the miter gauge is locked at an angle other than 0 degrees. Always use the miter slot (D) which allows the blade to tilt away

from the miter gauge and hands.

D

RIPPING

MITERING

Mitering (Fig. 49) is the same as crosscutting except the miter gauge (C) is locked at an angle other than 0°. Hold the workpiece

firmly against the miter gauge and feed the work slowly into the blade to prevent the workpiece from moving.

Use caution when starting the cut to prevent

binding of the guard against the workpiece. Miter angles

greater than 45° may force the guard into the saw blade

and damage the guard. Before starting the motor, test

the operation by feeding the workpiece into the guard. If

the guard contacts the blade, place the workpiece under

the guard, not touching the blade, before starting the

motor. Certain workpiece shapes, such as mouldings,

may not lift the guard properly. Feed the work slowly to

start the cut.

C

Ripping (Fig. 52) is cutting lengthwise through a board. The rip fence (A) is used to position and guide the work. One edge

of the work rides against the rip fence while the flat side of the board rests on the table.

You must use the saw blade guard. On Delta saws, the guard has anti-kickback pawls to prevent

kickback, and a splitter to prevent the wood kerf from closing and binding the blade. Be sure to replace or sharpen

the anti-kickback devices when the points become dull.

Always use a rip fence for ripping operations. NEVER perform a ripping operation free-hand. Always

lock the fence to the rail.

The workpiece must have a straight edge against the fence, and must not be warped, twisted or bowed.

Fig. 49

Fig. 50 Fig. 51