Dual Servo Spin Welder User’s Manual

Dukane Manual Part No. 403-570-01Page 76

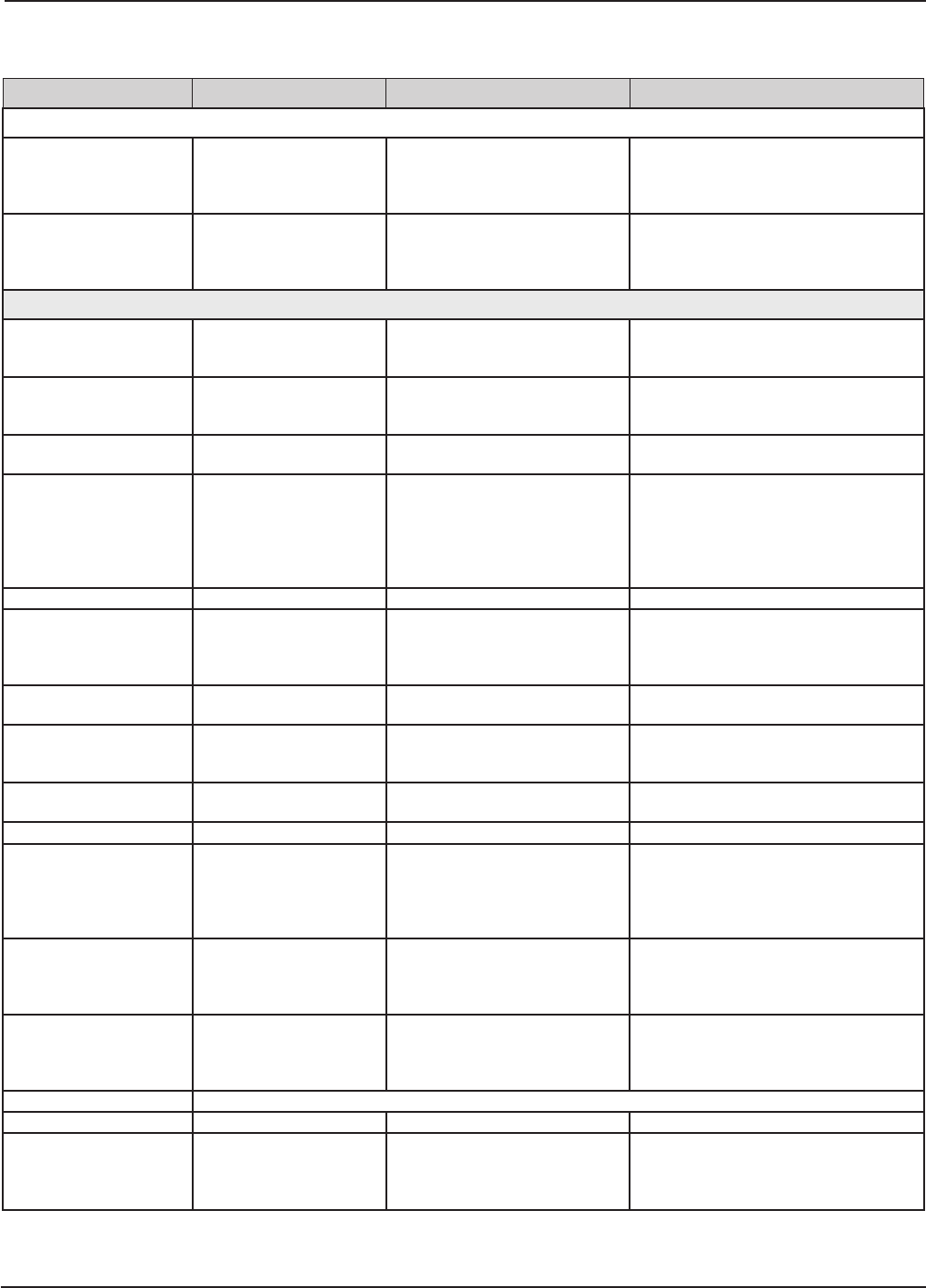

Message Description Cause Possible Solution

Instructions

Activate both RUN

SWITCHES to reset

machine

Resetting of machine at

startup or recovery requires

the activation of both optical

switches on base.

- -

Activate both RUN

SWITCHES to reset

machine after all motion

stops

Resetting of machine at

startup or recovery must be

initiated when the spin tool

and press are stationary.

- -

Faults

Axis move aborted

Expected servo move was

not completed

Internal machine error

1. Check for obstructions to motion

outside welder

2. Contact DUKANE service

Home index edge not

found

Spin or vertical servo motor

internal index pulse(s) not

detected

Internal machine error Contact DUKANE service

Improper servo operation

request

Servo controller error Internal machine error Contact DUKANE service

Jog thrust limit exceeded

OR vertical servo runaway

detected

Press thrust (force) was

exceeded during jogging

operations OR servo

system entered runaway

condition

1. Press is jogged in a way to

produce a force on the parts

larger than allowed in jog

mode (most common cause)

2. Servo system feedback is

malfunctioning

1. Prevent press from applying a large

force on the parts in jog mode

2. Contact DUKANE service

Operator E-Stop E-stop activated Operator pressed E-stop switch Reset E-stop switch then reset machine

Part pickup not detected

Sensor for upper tool

vacuum not activated when

expected

1. No part present to pick up

2. Loss of vacuum between part

and tool

1. Ensure part is present for pickup

2. Check vacuum between part and tool

(line connections, vacuum generator,

tool wear)

Part presence not detected

Part presence sensor did

not detect part

1. Part not present

2. Problem with sensor

1. Ensure part is present

2. Troubleshoot sensing components

RUN SWITCH(ES)

released too soon

Optical switches on base

were de-activated during

weld cycle

Switches were released after weld

cycle started but before the spin

motor stopped

Once weld cycle is started, ensure switches

remain activated until spin motor stops (i.e.

at beginning of hold phase)

Servo CPU no Idle before

Run

Motor controller error Internal machine error Contact DUKANE service

Servo CPU program error Motor controller error Internal machine error Contact DUKANE service

Servo database import

failed

Servo tuning database

import failed

1. Import procedure problem

2. Cable problem

3. Machine component failure

1. Contact DUKANE for import

procedure

2. Check that the correct cable is used

and that it is securely connected

3. Contact DUKANE service

Servo param select by

inertia failed

Servo tuning data not

found for the tooling inertia

entered

1. Tooling inertia entered is

outside allowable range

2. Servo tuning database is

missing

1. Enter tooling inertia within limits stated

in this manual

2. Contact DUKANE regarding importing

servo tuning database

Slide In timeout

Slide did not move to the

commanded position within

the allowable time

1. Air pressure to slide too low

2. Slide limit switch improperly

positioned

3. Slide jammed

1. Increase air pressure

2. Adjust slide switch position

3. Ensure slide can move freely

Slide Out timeout see Slide In timeout fault

Spin aborted Weld cycle was aborted Internal machine error Contact DUKANE service

Spin at travel limit

Number of servo motor

rotations has exceeded

controller counting

capability

Weld time or number of rotations

too large

Reduce weld time, distance, or number of

rotations

Table 9-II Machine Display Messages