13

MODEL 228 CALIBRATION

CALIBRATION

The nominal cell constant of the Model 228 sensor is 2.7/cm. The error in the cell constant is about ±10%, so con-

ductivity readings made using the nominal cell constant will have an error of at least ±10%. Wall effects, discussed

below, will likely make the error greater. For higher accuracy, the sensor must be calibrated.

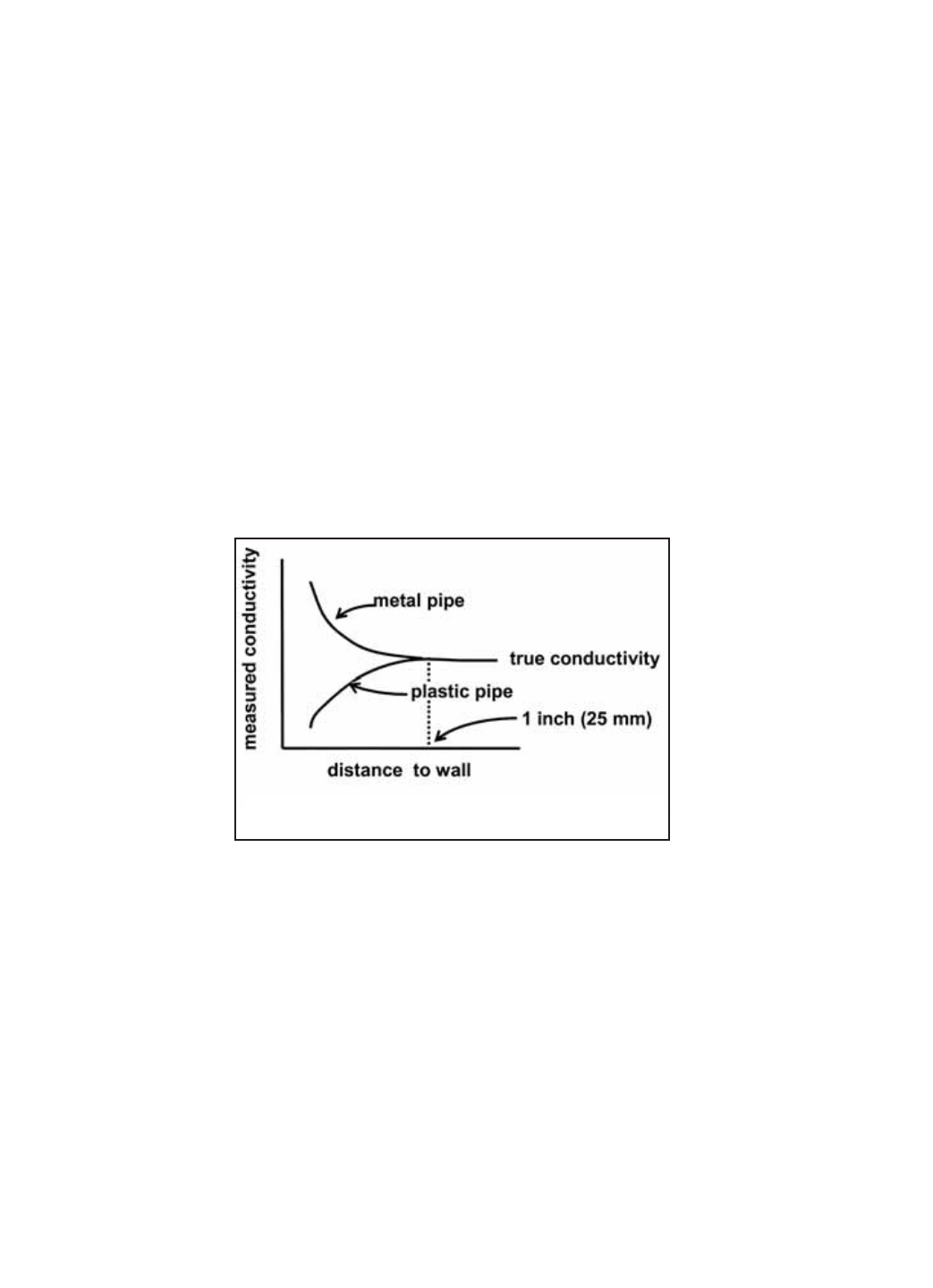

Wall effects arise from the interaction between the current induced in the sample by the sensor and nearby pipe

or vessel walls. As Figure 18 shows, the measured conductivity can either increase or decrease depending on the

wall material. Because wall effects do not disappear until the Model 228 sensor is at least 1 inch (25 mm) away

from the nearest wall, wall effects are present in most installations. Correcting for them is an important part of cal-

ibration.

Conductivity sensors are calibrated against a solution of known conductivity (a standard) or against a previously

calibrated referee sensor and analyzer. If wall effects are present, calibrating a toroidal sensor with a standard

solution is possible only if the vessel holding the standard has exactly the same dimensions as the process pip-

ing. If the Model 228 sensor is installed in a tee, duplicating the process environment in the laboratory or shop

might be possible. Otherwise, calibration against a standard solution is probably impractical. The alternative is to

calibrate the sensor in place against a referee sensor and analyzer, ideally while both sensors are simultaneously

measuring the same process liquid. If this is not practical, calibrate the process sensor against the results of a

measurement made on a grab sample.

For more information about calibrating toroidal conductivity sensors, refer to application sheet ADS 43-025 available

on the Rosemount Analytical website.

FIGURE 18. Measured conductivity as a function

of clearance between sensor and walls