NGA 2000 CLD

Instruction Manual

HAS60E-IM-HW

June 2007

2 - 2 Installation Emerson Process Management GmbH & Co.OHG

CAUTION

EXTERNALLY RESTRICT SAMPLE/CALIBRATION

GAS FLOW TO LESS THAN 2,200 cc/min.

Damage to internal components may occur if this

flow level is exceeded.

No restrictor is provided in the sample inlet of this

module. For those users who cannot externally

limit sample flow, contact your local service or

sales office.

2-3 LOCATION

Install the CLD Analyzer Module in a clean, weather-pro-

tected, vibration-free location free from extreme tempera-

ture variations and moisture. For best results, install the

instrument near the sample stream to minimize sample

transport time.

The analyzer should be installed within ±15° of horizon-

tal.

NOTE

Unrestricted air flow to the rear of the Analyzer Mod-

ule is critical to its performance and reliablilty.

Operating ambient temperature is 0 °C to 45 °C (32 °F to

113 °F). Temperature change should not exceed 10 °C

(18 °F) per hour. The same temperature range restric-

tions apply to the location of the air and span gas cylin-

ders.

2-4 GASES

a. Gas Conditioning (Sample Handling)

NOTE

All gases must be conditioned before supplying!

The gases must be

- dry

- free of dust (filtered for particulates down to two

microns)

- free of aggressive components affecting gas paths

materials (e.g. by corrosion)

- free of Ammonia etc. in order to prevent crystallin

formation

before entering the Analyzer Module.

The gases should have a dew point 5 °C (13 °F) below

coldest ambient temperature.

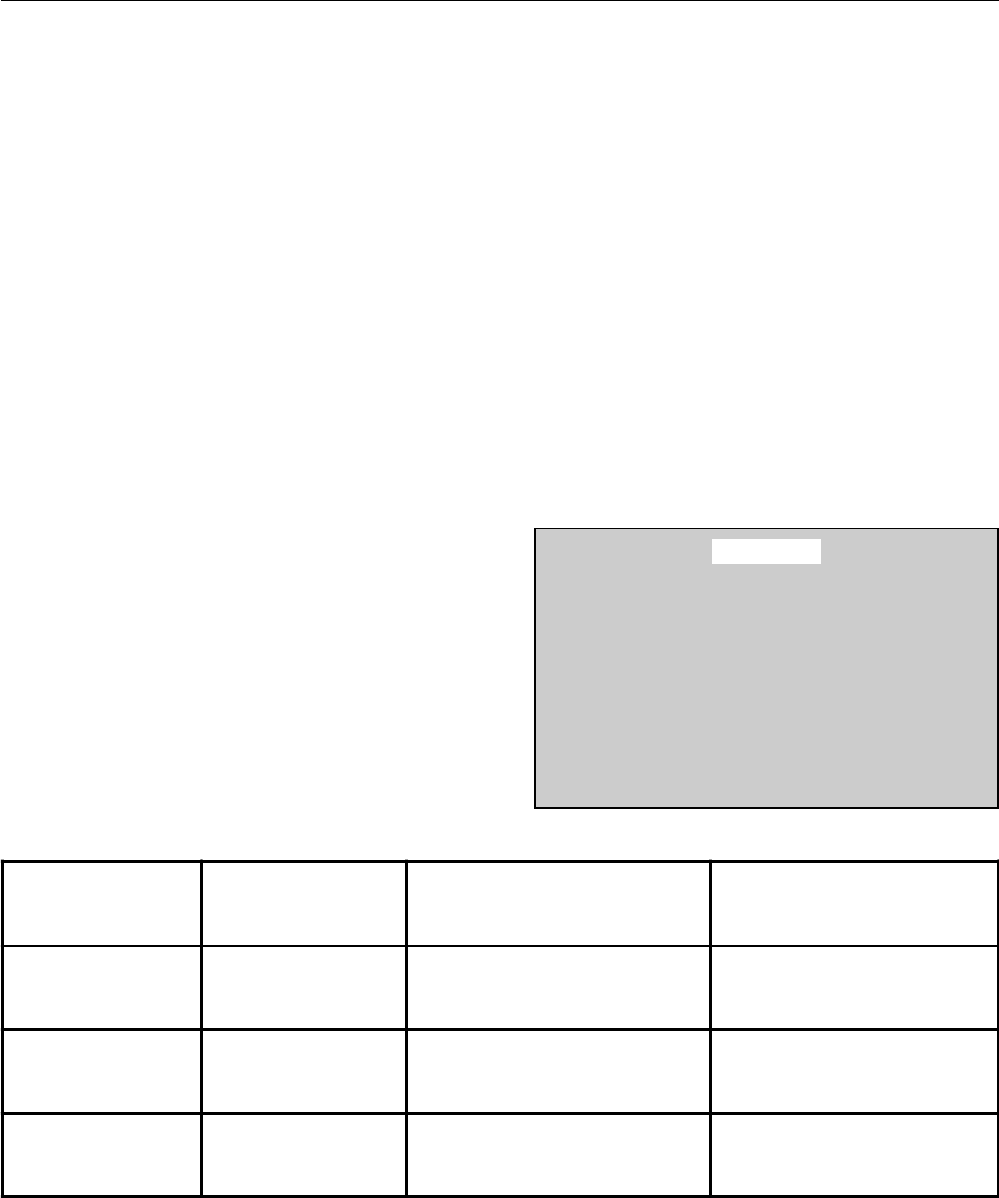

Table 2-1: Gas Specifications

MAXIMUM NO

x

LEVEL IN PARTS

PER MILLION

GAS SUPPLIED TO

REAR PANEL AIR

INLET

SETTING ON OZONE

PRESSURE GAUGE

(pressure values: gauge)

SETTING ON SAMPLE

PRESSURE GAUGE

(pressure values: gauge)

800 Air

690 hPa (10 psig); provides flow

of approximately 500 cc/min. to

ozone generator

344 hPa (5 psig); provides flow

of approximately 200 cc/min. to

reaction chamber

2,500 Air

690 hPa (10 psig); provides flow

of approximately 1,000 cc/min. to

ozone generator.

344 hPa (5 psig); provides flow

of approximately 70 cc/min. to

reaction chamber.

10,000 Oxygen

1035 hPa (15 psig); provides flow

of approximately 1,000 cc/min to

ozone generator.

103 hPa (1.5 psig); procides

flow of approximately 20 cc/min.

to reaction chamber.