19 2008SSD-34 (5/08)

Dual-Compressor Module Maintenance

CHECK FOR THESE CONDITIONS UNDER NORMAL OPERATION:

___ 1. Compressor speed should range from 2400 to 4800 rpm during normal operation.

___ 2. Suction pressure range is model specifi c.

___ 3. Discharge pressure should range from 70 psig to 190 psig, depending on the model

(see Compressor Module Nomenclature on page iv).

___ 4. Pressure differential between suction and discharge is at least 70 psi.

___ 5. First-stage separator temperature should be between 170°F and 220°F (77-104°C) model specifi c.

___ 6. Oil cooler fans should either run continuously or cycle periodically under normal conditions.

If any of these conditions are not met during normal operation, shut down the unit and refer to 5.0 -

Troubleshooting on page 27.

4.0 MAINTENANCE

4.1 Routine Maintenance

Perform the maintenance procedures in Table 5 at least once per year or more often if needed.

Oil consumption varies by application and during initial operation. Monitor the oil level routinely to

determine a consistent pattern of actual consumption.

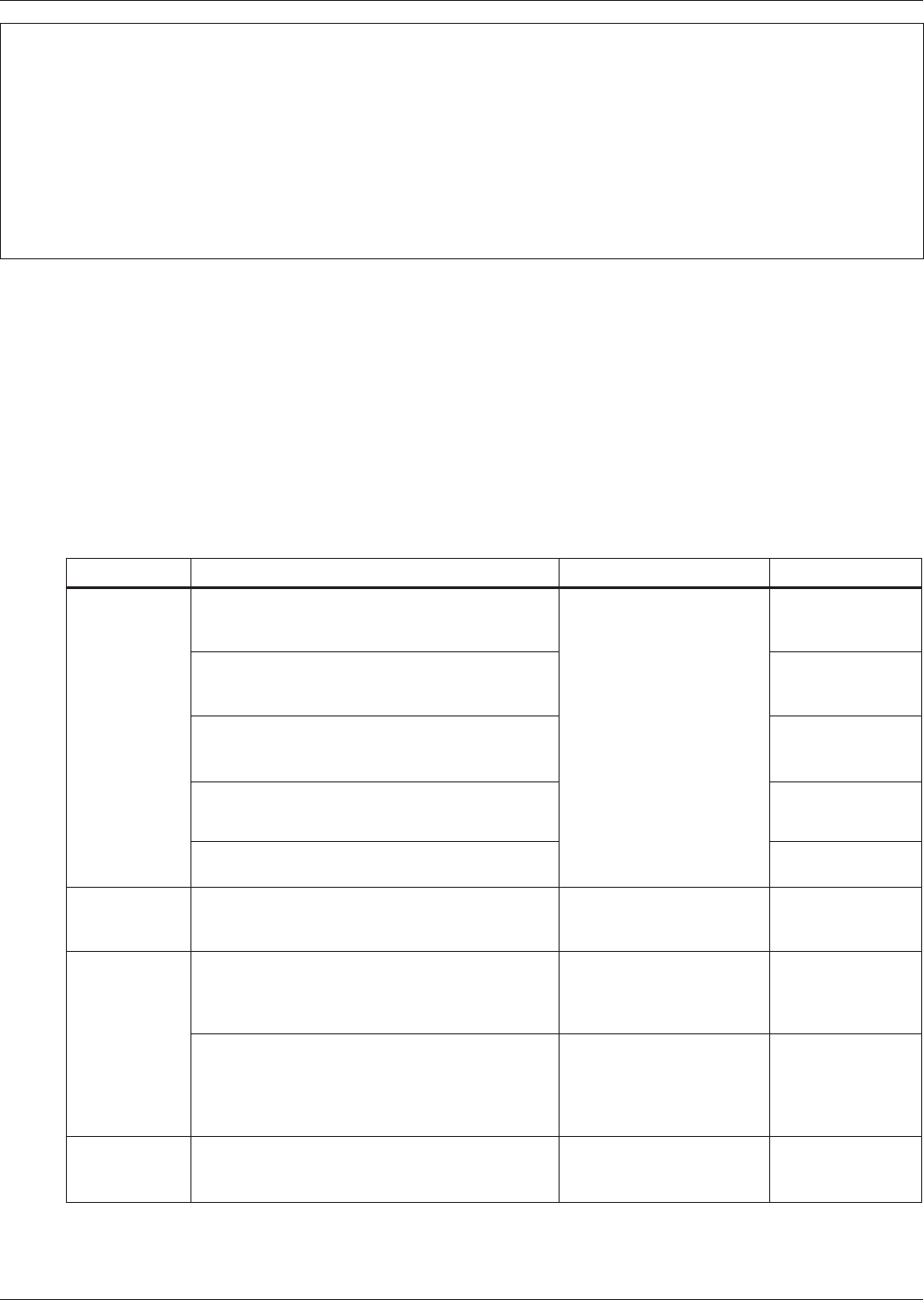

Table 5 Maintenance summary

Components Maintenance Reason For details, see:

Lubrication

& Cooling

System

• Monitor and check the oil level.

A low oil level or loss

of oil in the system will

result in overheating or

mechanical failure.

A high oil level may result

in excessive oil carryover

and oil discharge from

the Compressor Module

when the Compressors

are turned off.

4.3 - Checking

the Oil Level

(page 20)

• Add oil as needed.

4.5.1 - Topping

Off the Oil Level

(page 21)

• Change oil annually.

Note: Some applications may require more

frequent service.

4.5.2 - Changing

the Oil

(page 22)

• Check the condition of the lubricant

periodically. Normal color is clear or light

gray.

—

• Change the oil fi lter (if equipped) annually

or as required.

—

Gas Inlet

System

• Inspect and clean the inlet screen annually

or more often as needed.

A restricted inlet screen

will result in reduced fl ow.

4.6 - Cleaning

the Inlet Screen

(page 24)

Second-

Stage

Separator

System

• Inspect and clean the scavenge line orifi ce

annually or more often as needed.

A restricted scavenge

line orifi ce will result in

excessive oil carryover.

4.7 - Servicing

the Scavenge

Line Orifi ce

(page 24)

• Change the second-stage oil separator

element annually or more often if

contaminated.

Note: Some applications may require more

frequent service.

A dirty or plugged

separator element will

result in excessive oil

carryover.

4.8 - Changing

the Second-

Stage Separator

Element

(page 25)

Oil Heat

Exchanger

• Ensure heat exchanger cooling fi ns are clear

of dust and debris.

• Verify that the fans run freely.

——

See 5.0 - Troubleshooting on page 27 for additional details.