5 – 7

VSG/VSSG • Installation, Operation and Maintenance Manual •Vilter/Emerson • 35391SSG

Section 5 • Maintenance/Service

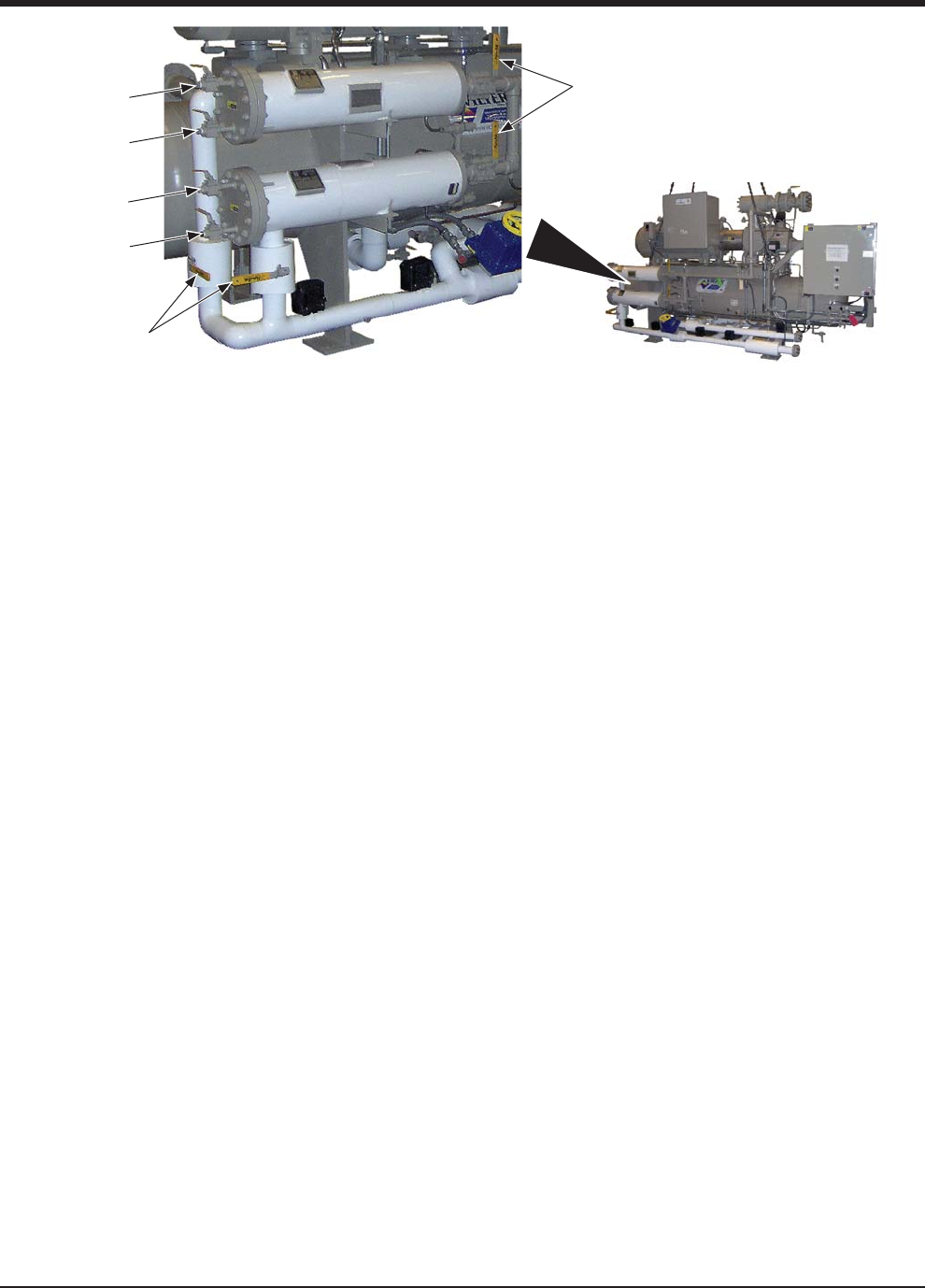

1. If equipped with dual oil fi lters, open inlet shut-off

valve for non-operating oil fi lter to put it into opera-

tion, see Figure 5-5.

2. To isolate oil fi lter for servicing, close inlet and out-

let shut-off valves for the oil fi lter.

NOTE

To reduce unwanted oil splash from a vent or drain

valve, connect a hose to the valve port and direct

the gas and oil into a drain pan.

3. Slowly release pressure in the oil fi lter canister by

opening the vent valve. Allow pressures to equalize

to atmosphere.

NOTICE

Dispose of the oil in a appropriate manner following

all Local, State and Federal ordinances regarding the

disposal of used oil.

4. Using an drain pan, open drain valve and allow the

oil to completely drain from the oil fi lter canister.

NOTE

Note orientation of components to aid in installation.

5. Remove bolts and nuts securing cover fl ange to the

oil fi lter canister. Remove cover fl ange and spring

plate. Retain spring plate.

6. If equipped with a single oil fi lter element, remove

fi lter element from oil fi lter canister.

7. If equipped with dual oil fi lter elements, remove

two fi lter elements and fi lter element centering

piece from oil fi lter canister. Retain fi lter element

centering piece.

8. Thoroughly clean the oil fi lter canister, spring

plate and centering piece. Inspect spring plate and

Figure 5-5. Oil Filter Drain, Vent and Shut-Off Valves

Drain Valve

Inlet Shut-Off Valves

Vent Valve

Drain Valve

Vent Valve

Outlet Shut-Off Valves

centering piece, if damaged, replace as required.

INSTALLATION

NOTE

Ensure oil fi lter element on the outlet side is fully

seated on the outlet pipe when installed.

9. If equipped with single oil fi lter element, install oil

fi lter element in canister in orientation noted dur-

ing removal.

10. If equipped with dual oil fi lter elements, install two

oil fi lter elements and centering piece in orientation

noted during removal.

11. Position spring plate in orientation noted during

removal and install bolts and nuts to secure cover

fl ange to oil fi lter canister.

12. Tighten nuts, see Appendix A.

13. Using dry nitrogen gas, pressurize oil fi lter canister

through vent valve and check for leaks.

14. Close the vent valve and drain valve.

15. Open outlet shut-off valve for the oil fi lter that is not

in operation.

16. Repeat for second oil fi lter, as required.