24 Kapex KS120 Miter Saw

Calibration and Adjustment

The Festool Kapex miter saw comes fully calibrated from

the factory and should not require further calibration out of

the box or after normal use. The following calibration

techniques should only be necessary in the event that your

saw is knocked out of alignment, such as can happen

during frequent, or unsecured transport. Use these

procedures only when your saw needs service.

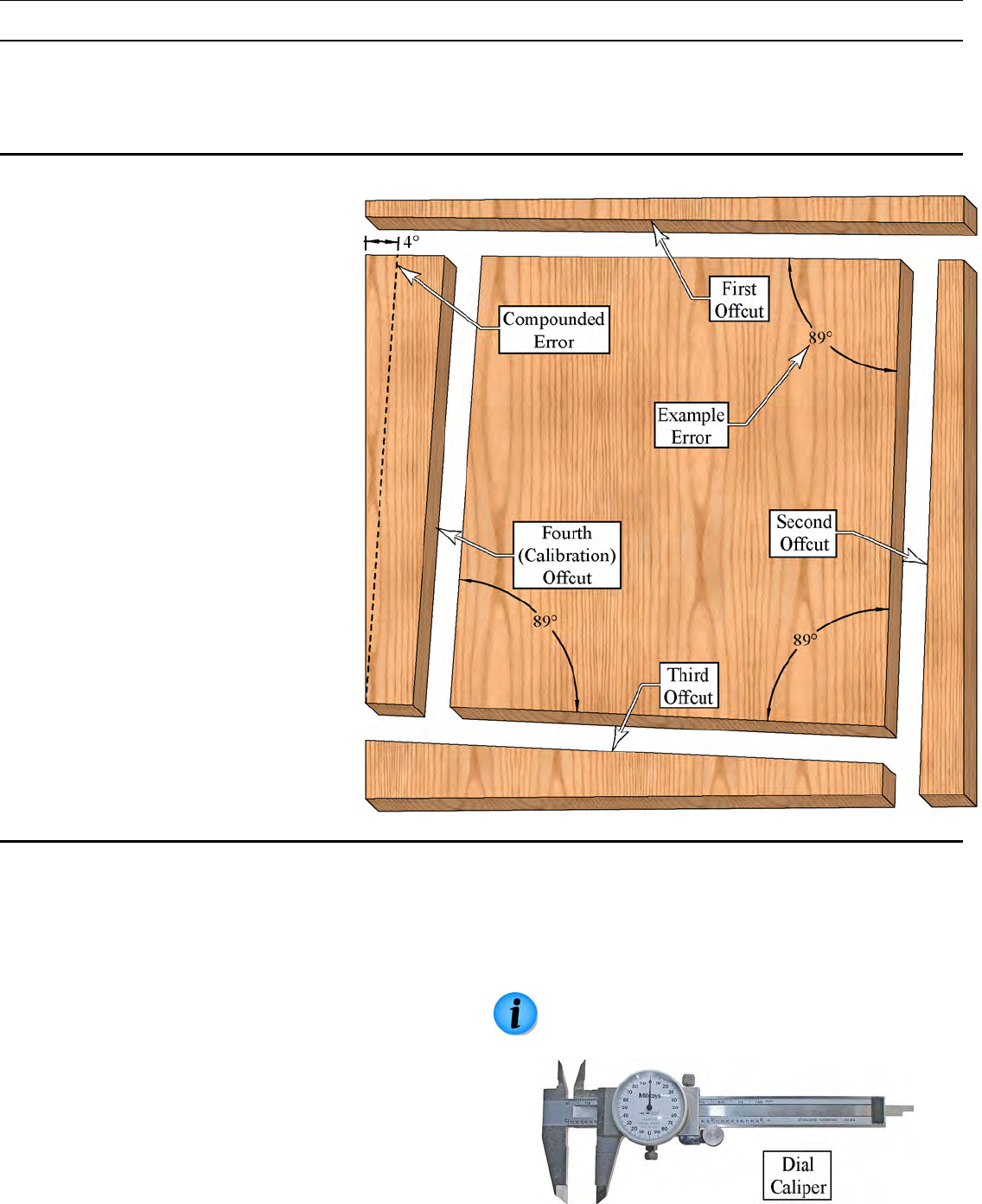

Calibrating the Miter Angle

The calibration method described here is

based on compounding an error by a factor

of four. This makes it easier to detect

extremely small calibration errors. However,

care should be taken in over-using this

calibration procedure because it has such a

fine accuracy that it could be easy to get

carried away and try to over-calibrate the

saw. The factory calibration threshold is

±0.16°, but this calibration procedure is

capable of measuring errors as low as

±0.001°, which is nearly impossible to

obtain in actual practice.

The basis for this procedure is to make four

successive cuts, where each new cut

references from the previous cut. As a r

any angular error in the miter angle will

propagate and be compounded with each

cut. The final cutting error will have 4-times

the actual error of the saw. In the diagram

to the right, you can see that each

successive offcut has a slightly larger angle

than the previous offcut.

esult,

You may have heard of this method referred

to as the “5-cut Calibration Method”, but as

long as you start out with a straight edge on

the board, only 4-cuts are required.

Furthermore, any additional cuts made after

the fourth cut will not increase the accuracy,

and it will remain at 4-times the original

error.

Getting Started

You will need a piece of scrap wood that is between 6 and

12 inches on a side. The scrap does not need to be

perfectly square, but at least the first edge must be

straight. The larger the piece, the more accurate your final

measurement will be.

The material can be anything, but Medium Density

Fiberboard (MDF) will give you the cleanest cuts, and

therefore, the easiest to measure.

► High density plywood, such as Baltic birch, will also give

very accurate results.

► Low-grade plywood may have rough edges, depending

on the quality, and therefore, may provide the lowest

accuracy.

► Solid wood can also be used, but you may experience

burning on the rip-cuts if you are using a fine-tooth

blade.

You will need a ruler to measure the length of the final

offcut, and optionally, a dial caliper to accurately measure

the difference in the width of the offcut at both ends. This

width measurement is the most critical, so a dial caliper is

recommended.

It does not matter whether your measurements

are in metric units or imperial units.