18 Kapex KS120 Miter Saw

Miter Cuts

Miter cuts are used when a board needs to be cut at an

angle across its width. The most common application for a

miter cut is for joining two boards to form a corner without

endgrain showing. The miter angle is one-half of the

corner angle. So for a 90° corner, for example, the miter

angle is 45°.

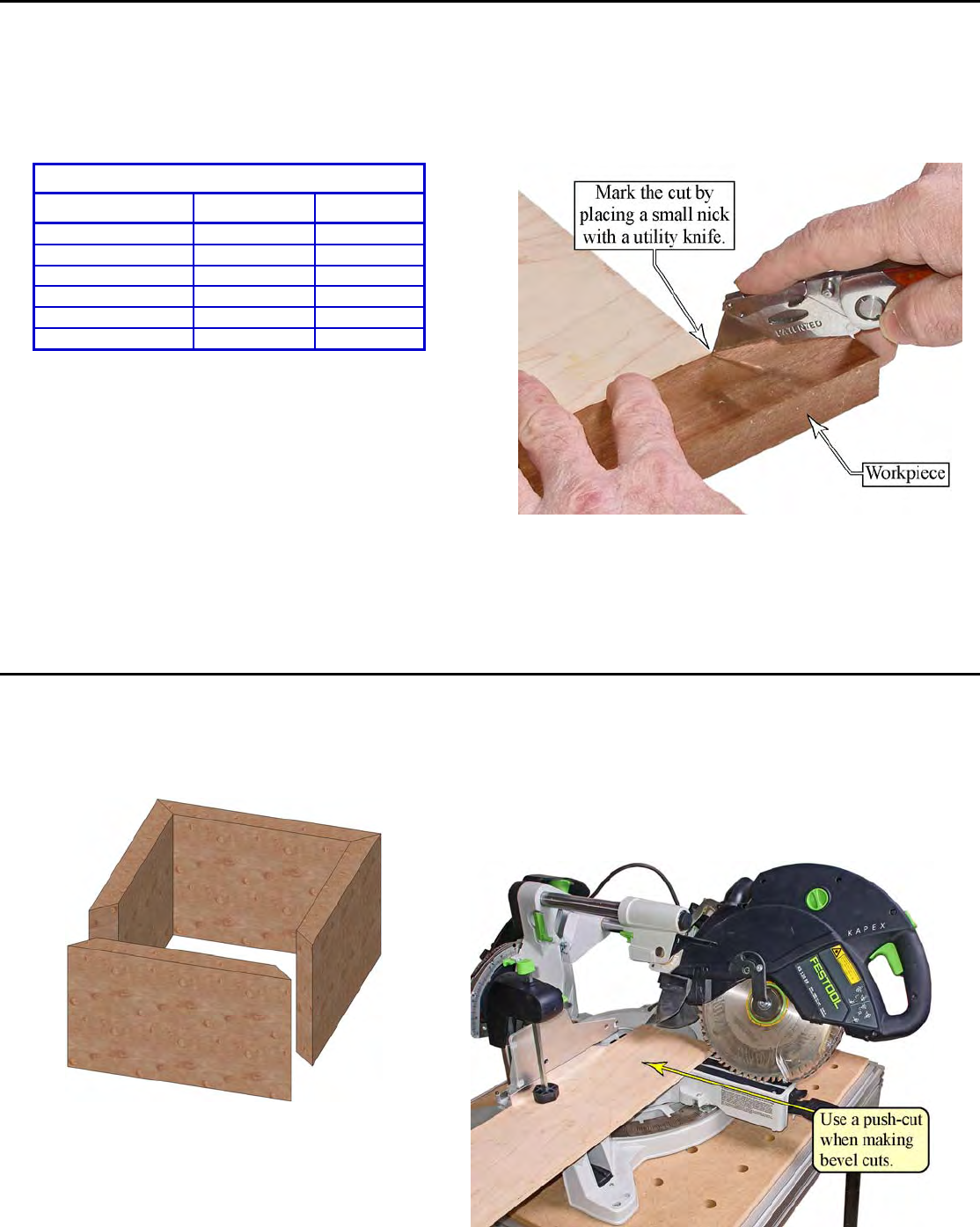

Miter Angles for Polygons

Number of sides Corner Angle

Miter Angle

3 – Triangle 120 60

4 – Square 90 45

5 – Pentagon 72 36

6 – Hexagon 60 30

7 – Heptagon 51.4 25.7

8 – Octagon 45 22.5

For even the most experienced woodworkers, cutting

accurate and tight fitting miters can be problematic. The

following are some tips for making accurate miters.

► Clamp the workpiece down. Because the sawblade is

cutting at an angle with the workpiece edge and fence, it

will tend to move the workpiece sideways, in the

direction of the cut, as the cut progresses. This can

result in a cut that is not straight, or the angle of the cut

may be off.

► Cut slowly. Cutting too rapidly can cause the sawblade to

deflect as it encounters varying densities in the

woodgrain.

► Use a chop-cut only for narrow miters. When in doubt,

use a push-cut.

► When marking the length of the workpiece, use a sharp

pencil to draw a thin line. The thicker the line, the more

difficult it will be to cut accurately on the line.

► When marking a workpiece length to match a wall or

other structure, use a utility knife to mark the cut with a

small nick. This is more accurate than a pencil line.

► If a utility knife is used to mark the cut, you can use a

method called “Sneaking up on the cut.” This is where

you make an initial cut longer than needed, and

continually make very small re-cuts until the cut line

splits through the center of the nick you made with the

utility knife.

Bevel Cuts

Bevel cuts are used when a board needs to be cut at

an angle across its thickness. The most common

application for a bevel cut is for constructing a box or

similar structure.

The following are tips for making accurate bevel cuts:

► Clamp the workpiece down. If the workpiece is not

held firmly, the blade will tend to pull the workpiece

into the cut and up the blade.

► For best results, use only a push-cut.

► Take care not to deflect the saw head sideways.

Because the saw head is tilted to the side, it can be

easy to inadvertently push the saw head down or pull it up

as you feed the saw into the cut. This will result in a crooked

cut.

► Place the workpiece on the saw with the best-side down.

Because of the angle of the blade teeth exiting the workpiece

on the top side of the cut, there will be slightly more tearout

on the top, especially on the sharper edge.