Supplemental User’s Manual 29

Troubleshooting

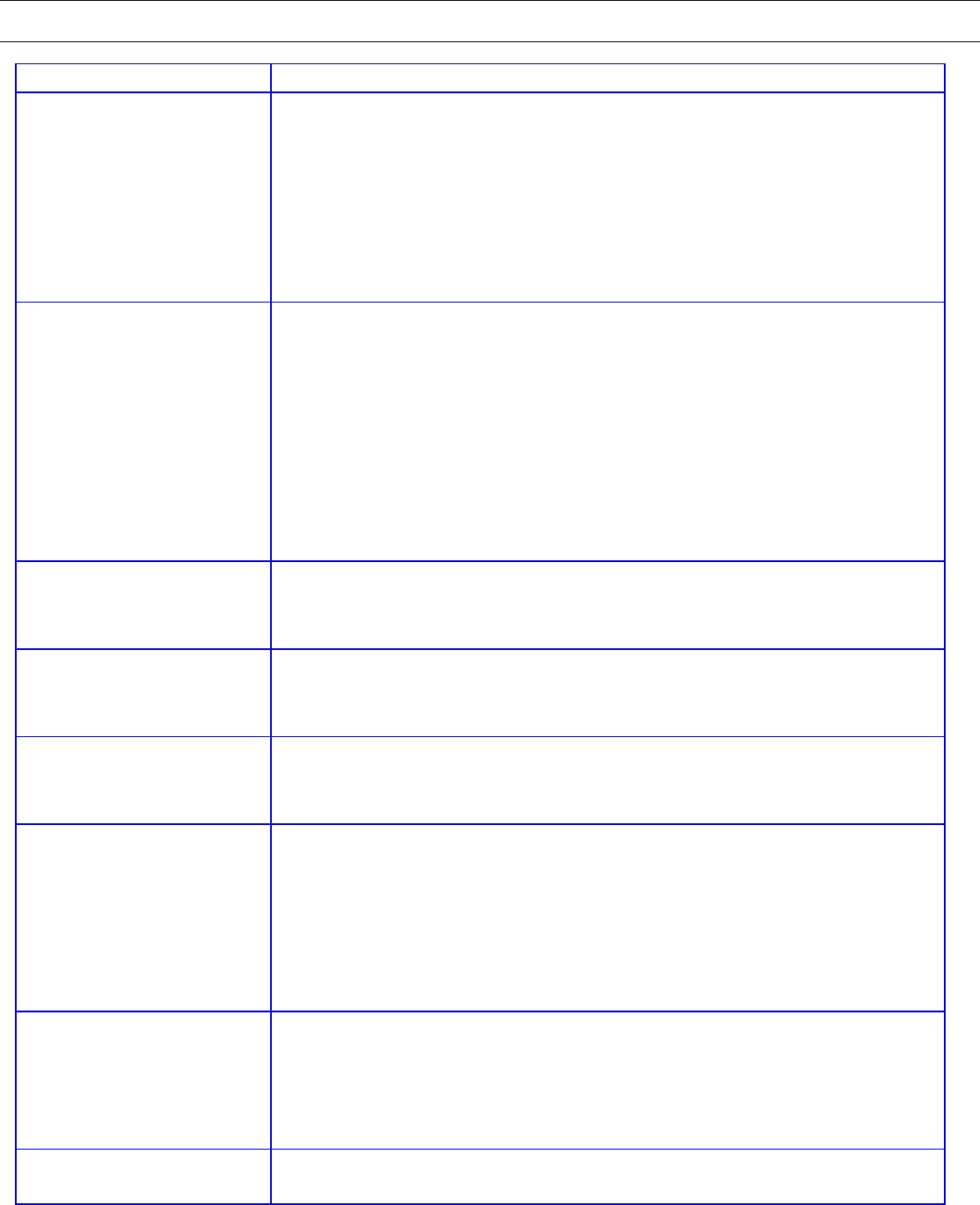

Symptom Possible Causes

Motor does not start ► Check that the cord is properly plugged into an outlet.

► Make sure the outlet has power. Check the circuit breaker or try another outlet.

► If used with a Festool dust extractor, make sure the selector switch is pointing to

"Auto". The auxiliary outlet on the dust extractor has power only when the

selector is at Auto.

► Inspect the power cord (including extension cords) for damage or missing

prongs.

► The motor brushes may have worn and need replacement.

Lasers do not work ► The lasers turn off automatically if the saw is not used for a period of time. Press

the Laser On/Off button to turn the lasers back on.

► Check that the cord is properly plugged into an outlet.

► Make sure the outlet has power. Check the circuit breaker or try another outlet.

► If used with a Festool dust extractor, make sure the selector switch is pointing to

"Auto". The auxiliary outlet on the dust extractor has power only when the

selector is at Auto.

► Inspect the power cord (including extension cords) for damage or missing

prongs.

► Inspect the laser dust lens for excessive dust (see page 28).

Excessive tearout on the

bottom edge of the cut

► This can occur with plunging and/or pulling cuts (see page 17).

► Too fast of a feed rate through the cut.

► Too coarse of a blade for a crosscut operation.

Excessive tearout on the top

side of the cut

► This can occur with a push cut, especially with thicker materials.

► Too fast of a feed rate through the cut.

► Too coarse of a blade for a crosscut operation.

Excessive tearout at the rear

of the cut

► This is common for plunge cuts, and slightly less prominent with push cuts.

► Too fast of a feed rate through the cut.

► Use a backing board or auxiliary fence.

Saw cuts are burning ► Make sure to use the correct blade for the material.

► Make sure the blade is sharp.

► Make sure the blade is installed correctly (not turning backward).

► Keep the workpiece clamped to prevent it from moving into the blade. This is

especially true for miters and bevels where the blade tends to pull the workpiece

into the blade.

► Reduce the motor speed.

Saw cuts are wavy ► Do not make plunge-then-pull type cuts, as this can lead to uneven cuts.

► Make sure to keep the workpiece firmly clamped in position, especially for miter

and bevel cuts.

► Don’t change the feed rate during the cut. Keep a constant and steady feed rate.

► Bent or damaged sawblade, such as missing teeth.

The Tall Miter Latch won't

engage

► Make sure the bevel setting is at zero degrees. The tall miter latch will not

engage if the saw head is tilted.