13

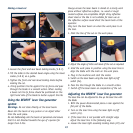

Making a bevel cut

1. Loosen the front and rear bevel locking knobs (5 & 7).

2. Tilt the table to the desired bevel angle using the bevel

scales (4 & 6) as a guide.

3. Tighten the front and rear bevel locking knobs before

making the cut.

4. Firmly position the tile against the rip fence and pass

through the blade in a smooth action. When making

a bevel cut the rip fence should be positioned on the

right hand side of the blade to better support the tile.

Using the REDEYE

®

laser line generator

system

Warnings. Do not stare directly at the laser beam.

Never aim the beam at any person or an object other

than the work piece.

Do not deliberately aim the beam at personnel and ensure

that it is not directed towards the eye of a person for

longer than 0.25s.

Always ensure the laser beam is aimed at a sturdy work

piece without reflective surfaces, i.e. wood or rough

coated surfaces are acceptable. Bright shiny reflective

sheet steel or the like is not suitable for laser use as

the reflective surface could direct the beam back at the

operator.

Only turn the laser beam on when the work piece is on

the tool.

1. Mark the line of the cut on the work piece.

2. Adjust the angle of mitre and bevel of the cut as required.

3. Hold the work piece in position using the laser line to

align the blade with the mark on the work piece.

4. Plug in the machine and start the motor.

5. Switch on the laser beam using the laser light on/off

switch (24).

6. Pass the tile through the blade in a smooth action.

7. Switch off the laser beam on completion of the cut.

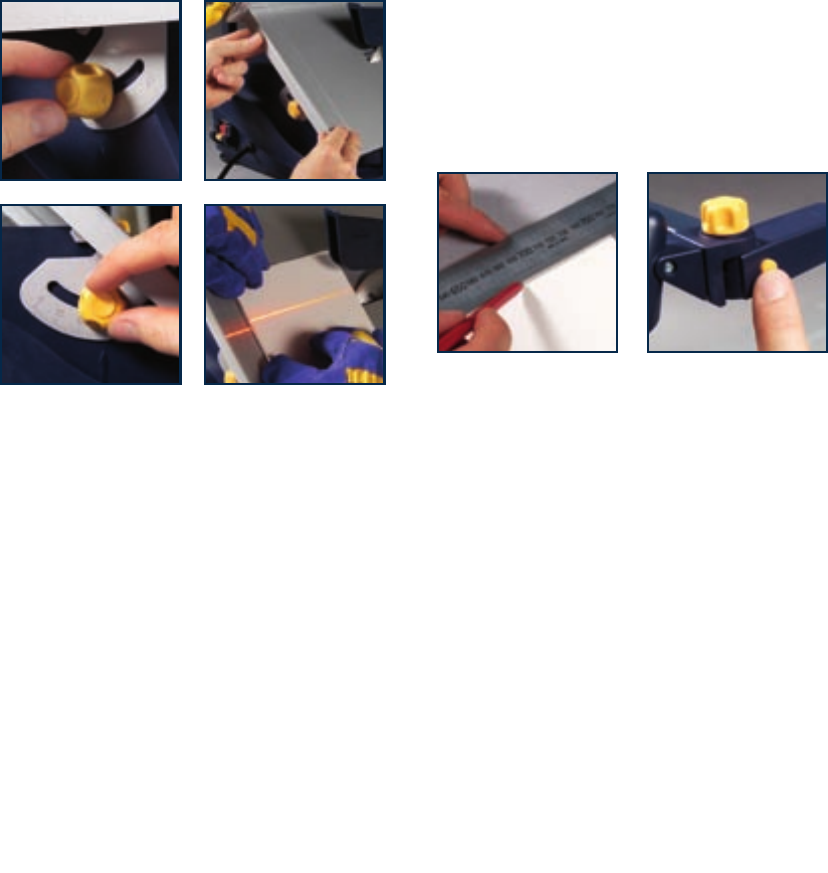

Adjusting the REDEYE

®

laser line generator

The laser line can be adjusted to line up the laser line with

the blade.

1. With the power disconnected place a ruler against the

flat part of the blade.

2. Turn on the laser line using the laser light on/off

switch (24).

3. If the laser line is not parallel with straight edge

adjust the laser line in the following way.

4. Loosen the laser light assembly locking knob (22) and