12

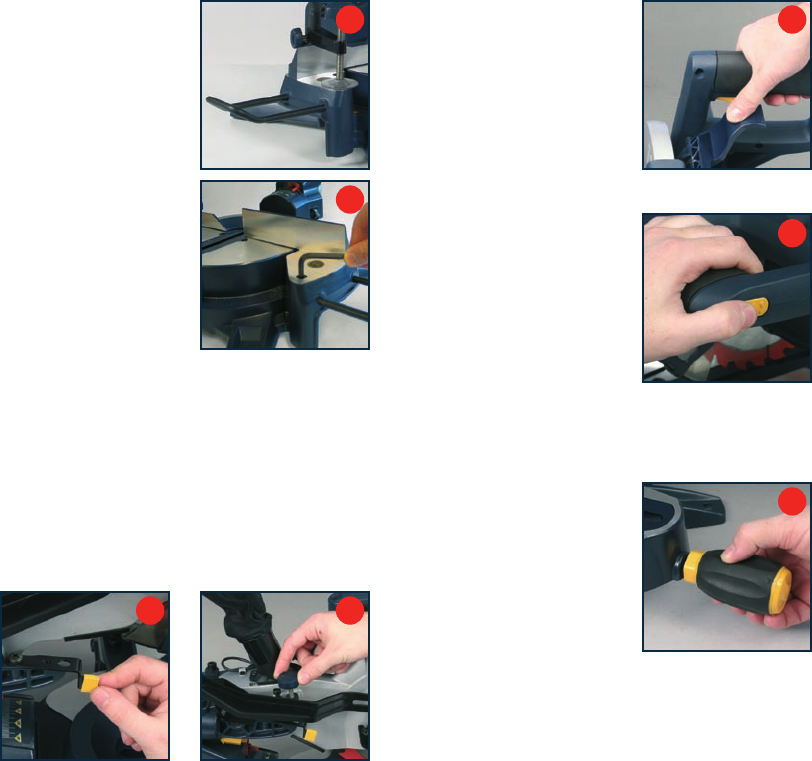

Attaching the side bars

The side support bars (36) help

to support the material when

working with long workpieces.

There are two location holes

(37) for a support bar on either

side of the table. Ensure the

side bars are fully inserted

before using them to support the

workpiece (Fig. L).

The side support bar locking

screws (38) must be tightened

to secure the support bars in

position (Fig. M).

Trench depth adjustment

In its normal position, the trenching stop (31) permits the

saw blade to cut right through a workpiece. When the saw

arm is lifted, the trenching stop can be moved to the left so

that the trenching depth adjustment screw (30) contacts the

stop as the saw arm is lowered. (Fig. N). This restricts the

cut to a “trench” in the workpiece. The depth of the trench

can be adjusted with the trenching depth adjustment screw

(30) (Fig. O) and locked in position with the trenching depth

lock nut (32).

Turning on and off

1. To turn the saw on depress

and hold the on/off trigger

switch (24) (Fig. P).

2. To turn the saw off release the

on/off trigger switch (24).

Turning on the REDEYE

®

laser line generator

The REDEYE

®

laser line

generator emits 2 intense narrow

beams of pure red light to guide

you as you cut. It improves

operator cutting vision, enables

faster set-up, increases accuracy

and improves safety. To turn on

the laser lines press the laser

light on/off switch (2) (Fig. Q).

To turn off the laser press the laser light on/off switch

(2) one more time.

Setting the table square with the blade

1. Make sure that the electrical

plug is removed from the

power point.

2. Push the saw arm (5) down

to its lowest position and

engage the release knob (6)

to hold the saw arm in the

transport position.

3. Loosen the mitre lock (25) (Fig. R).

4.

Rotate the table (21) until the pointer is positioned at 0º.

5.

Tighten the mitre lock (25).

L

M

O

N

P

Q

R