13

T

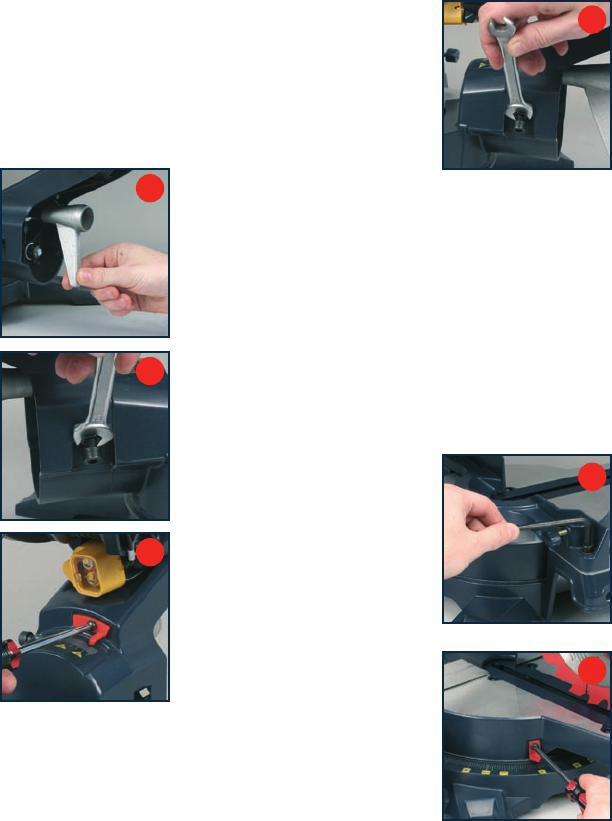

6. Loosen the bevel lock (16) and set the saw arm (5) at

0º bevel (the blade at 90º to the mitre table).

Tighten the

bevel lock (16)

(Fig. S)

.

7. Place a set square against the table (21) and the flat part

of the blade.

Note. Make sure that the square contacts the flat part of the

saw blade, not the teeth.

8. Rotate the blade by hand

and check the blade-to-table

alignment at several points.

9. The edge of the set square

and the saw blade should be

parallel.

10. If the saw blade angles away

from the set square, adjust

as follows.

11. Use a 13mm wrench or

adjustable wrench to loosen

the lock nut securing the 0°

bevel adjustment screw

(34) (Fig. T). Also, loosen the

bevel lock (16).

12. Adjust the 0° bevel

adjustment screw (34) with

the 6mm hex key to bring

the saw blade into alignment

with the square.

13. Loosen the Phillips head

screw holding the pointer

of the bevel scale (17) and

adjust the position of the

pointer so that it accurately

indicates zero on the scale.

Retighten the screw (Fig. U).

14. Retighten the bevel lock

(16) and the lock nut

securing the 0° bevel

adjustment screw (34).

Note. The above procedure can

also be used to check the angle

of the saw blade to the table at

45º bevel angle. The 45° bevel

adjustment screw (33) is on the

opposite side of the saw arm (Fig. V).

Setting the fence square with the table

1. Make sure that the electrical plug is removed from the

power point.

2. Push the saw arm (5) down to its lowest position and

engage the release knob (6) to hold the saw arm in the

transport position.

3. Loosen the mitre lock (25).

4. Rotate the table (21) until the pointer is positioned at 0º.

5. Tighten the mitre lock (25).

6. Using the 6mm hex key

provided, loosen the four

screws securing the fence (18)

to the base (Fig. W).

7. Place a square against the

fence (18) and alongside

the blade.

8. Adjust the fence (18) until it is

square with the blade.

9. Tighten the screws securing

the fence (18).

10. Loosen the Phillips head

screw holding the pointer

of the mitre scale (22) and

adjust it so that it accurately

indicates the zero position on

the mitre scale (Fig. X).

11. Retighten the screw securing the mitre scale pointer.

S

V

U

W

X