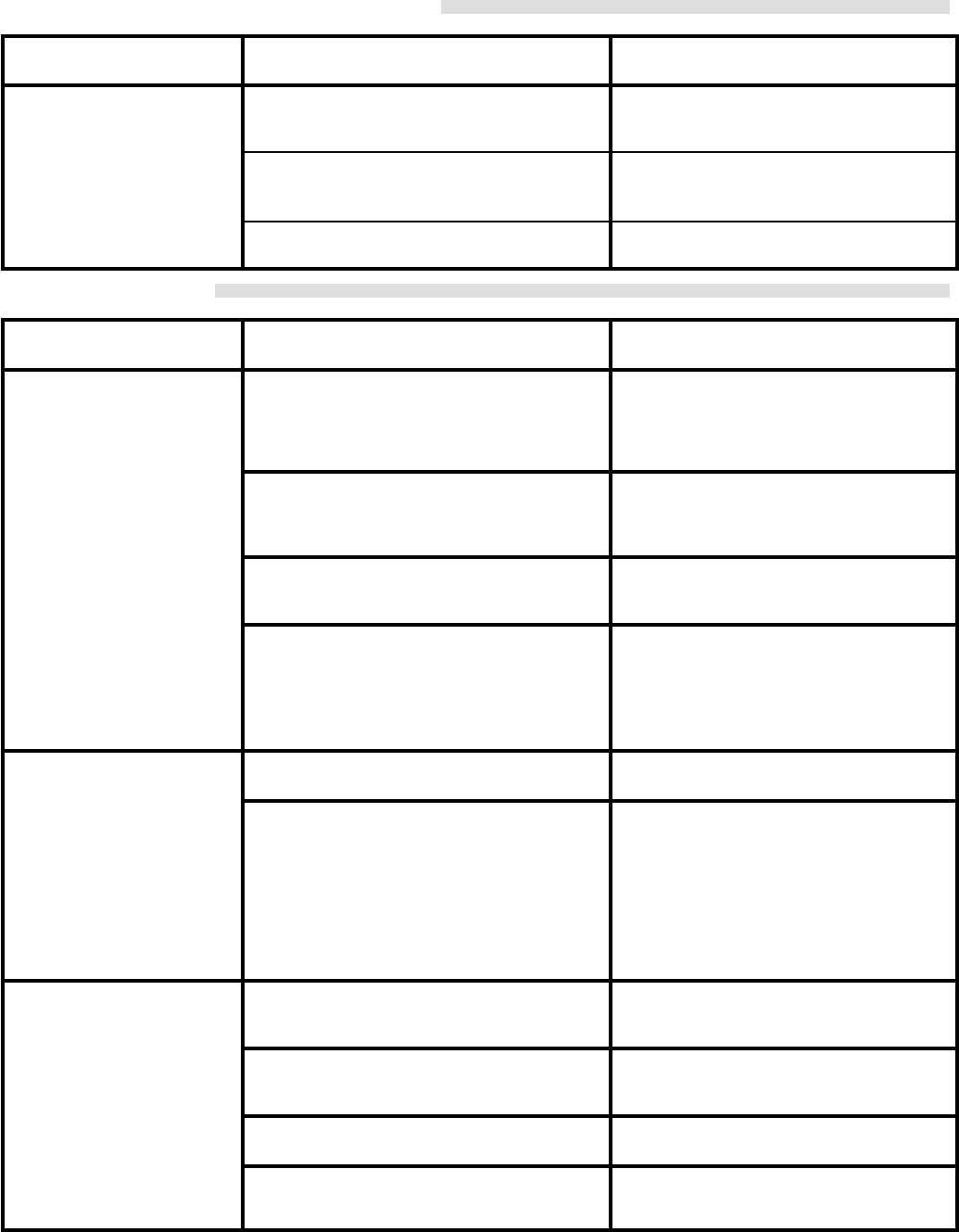

307–758 21

MOTOR

IS HOT

AND RUNS INTERMITTENTL

Y

TYPE

OF PROBLEM

WHAT

T

O CHECK

If check is OK, go to next check

WHA

T T

O DO

When check is not OK refer to this column

1. Determine if sprayer was operated at high

pressure with small tips, which causes low

motor

RPM and excessive heat build up.

1. Decrease pressure setting or increase tip

size.

2. Be sure ambient temperature where sprayer

is located is no more than 90

_F and sprayer

is

not located in direct sun.

2.

Move sprayer to shaded, cooler area, if

possible.

3. Determine

if was sprayer turned on, pressur

-

ized,

but not operating for long periods of time.

3 Turn

of

f

sprayer whenever you stop spray

-

ing

for a while and relieve fluid pressure.

ELECTRICAL

SHORT

TYPE

OF PROBLEM

WHAT

T

O CHECK

If check is OK, go to next check

WHA

T T

O DO

When check is not OK refer to this column

Building circuit breaker opens

as soon as sprayer switch is

turned

on.

1. Check

all electrical wiring

for damaged insula

-

tion,

and all terminals

for loose fit or damage.

Also check wires between pressure control

and motor which are encased in conduit (1).

See

page 34.

1. Repair or replace any damaged wiring or

terminals.

Securely reconnect all wires.

2. Check for missing inspection plate gasket

(see page 25), bent terminal forks or other

metal to metal contact points which could

cause

a short.

2.

Correct faulty conditions.

3. Check

motor armature for shorts. Use an ar

-

mature tester (growler) or perform spin test.

See

page 22. Inspect windings for burns.

3.

Replace motor

. See page 34.

4. Check bridge (308) by substituting with a

good

bridge or by performing

bridge test. See

pages

23 or 27.

CAUTION: Do not check bridge until arma-

ture

is determined to

be good. A bad armature

will

immediately burn out a good bridge.

4.

Replace bridge. See page 27.

1. Check ‘Basic Electrical Problems’ on page

16.

2. Check

ON/OFF switch (303) See page 26.

Be

sure the sprayer is unplugged!

Disconnect

wires

from switch. Check switch with

ohmme

-

ter.

The reading should be infinity with the ON/

OFF switch OFF

, and

zero with the switch ON.

CAUTION: A short

in the motor circuit burns

the bridge out immediately, which usually

causes

the ON/OFF switch to fail

in the closed

mode.

2. Replace

ON/OFF switch. See page 26.

Sprayer circuit breaker opens

after sprayer operates for 5 to

10

minutes.

1. Check

electrical supply with volt meter

. Meter

should

read 105 to 125 V

AC.

1.

If voltage is too high, do not operate

sprayer until corrected.

2. Check tightness of pump packing nut. Over-

tightening tightens packings on rod, restricts

pump

action, and damages packings.

2. Loosen packing nut. Check for leaking

around throat. Replace pump packings, if

necessary.

See page 36.

3. Check maximum working pressure adjust-

ment.

3. Perform

Pressure Control Adjustment. See

page

30.

4. After

determining that there is no

short in sys

-

tem,

reset circuit breaker button.

4. If

circuit

breaker continues to open (button

pops up), replace the circuit breaker. See

page

27.

.

CAUTION

Any short in any part of the

motor power circuit, which is

connected to the output side

of the bridge, will cause the

bridge to burn out immedi-

ately.

Correctly diagnose and

repair

all shorts before

check

-

ing

and replacing bridge.

Building circuit breaker

opens as soon as

sprayer is plugged into

outlet and sprayer is

NOT

turned on.