8

307–760

TROUBLESHOOTING GUIDE

Pressure

Relief Procedure

To

reduce the risk of serious bodily injury

, including

injury from moving parts or electric shock, always

follow

this procedure whenever you shut of

f the

sys

-

tem,

when checking or servicing any part of the sys

-

tem,

and whenever you stop painting.

1. T

urn the ON/OFF switch to OFF

.

2. Unplug the power supply cord.

3. T

rigger the roller valve to relieve pressure.

If

you suspect that pressure is not fully relieved after

following

the steps above, open the priming valve

2

turns

counterclockwise.

WARNING CAUTION

Thoroughly flush the system after each use to re-

duce

down time and costly repair bills.

NOTE:

If you are not able to determine the cause of

the

problem, or the problem and solution is not

dis

-

cussed

in this chart, return the system to an au

-

thorized

service agencyfor repair

.

PROBLEM CAUSE SOLUTION

Pump

will not prime or primes slowly

Clogged suction tube strainer

Clean.

Paint too thick

Thin; try pouring paint into suction tube;

use

3/8 in. ID hose if necessary

.

Outlet valve spring worn

Pour

paint into suction tube and try to prime

system.

If it doesn’t prime in one minute, re

-

place

the outlet valve spring. See page 1

1.

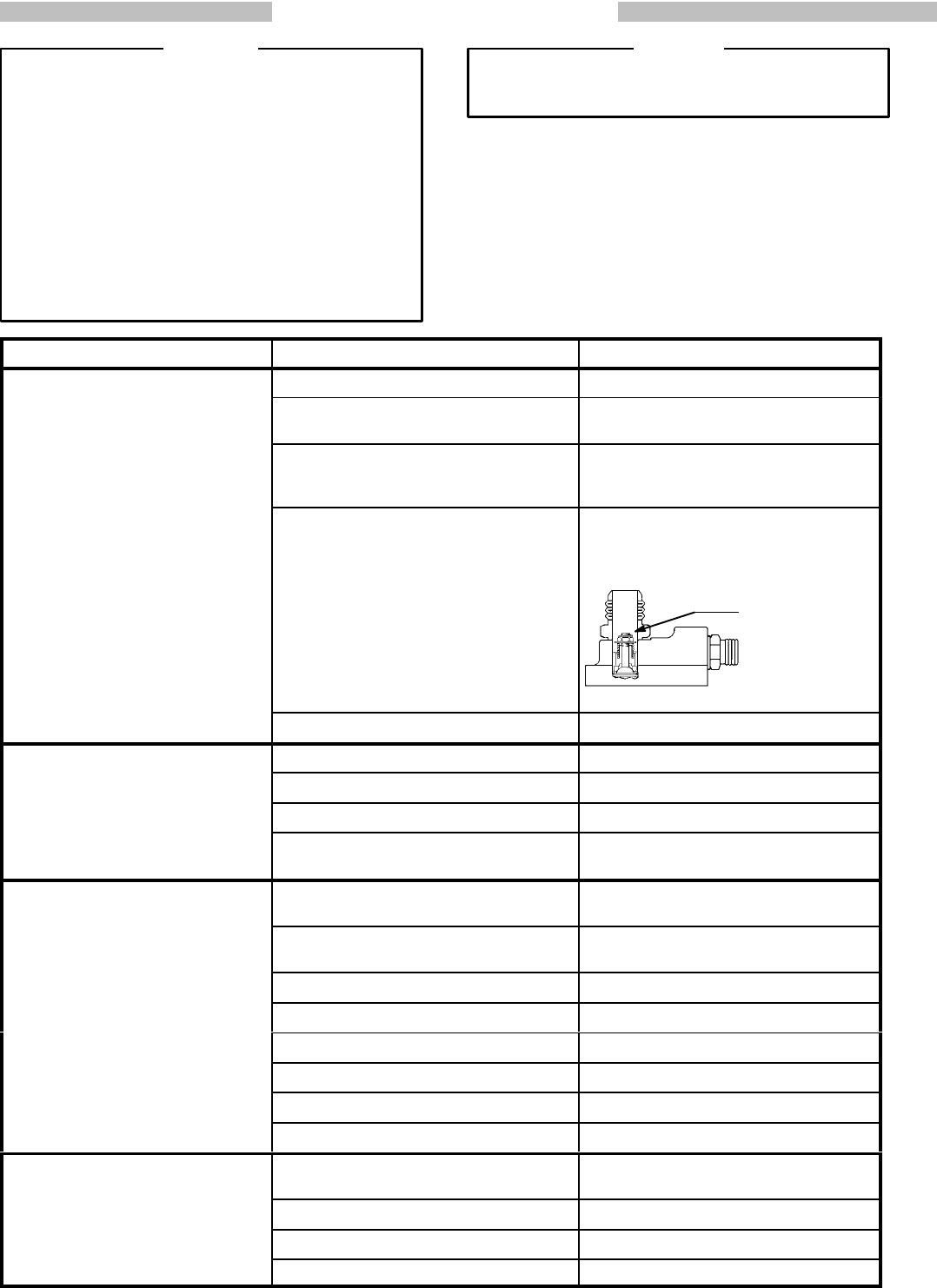

Inlet

valve stuck or damaged.

Depress inlet valve gently and pour in

about 1 teaspoon mineral spirits. Try to

prime pump. Replace inlet valve if neces-

sary.

See page 10.

Loose inlet hose nut

Tighten.

Pump wil not start

Power cord unplugged

Plug in.

ON/OFF switch turned off T

urn on.

Damaged motor

Replace. See page 13.

Fuse burned out.

Replace.

See page 10. If it burns out

again

quickly,

return the system for repair

.

Low paint flow or no paint flow

. Clogged roller valve, diffuser, roller frame,

roller

valve or hose

Clean

thoroughly

after each use. See page

6.

Using

more than 7.6 m (25 ft) of

1/4 in. ID hose

Use up to 30 m (100 ft) of 3/8 in. ID hose.

See

CAUTION

on page 17.

Loose inlet hose nut

Tighten.

W

orn priming valve

Replace. See page 12.

Priming valve is open

Close.

Paint too thick

Thin.

Damaged pressure switch

Replace. See page 1

1.

W

orn inlet and/or outlet valve

Replace. See page 1

1.

Pump runs after roller valve trigger is

released.

Worn pressure switch

Replace. See page 1

1.

W

orn inlet valve

Replace. See page 1

1.

W

orn priming valve

Replace. See page 12.

W

orn roller valve packings or needle

Repair

. See page 9.

DEPRESS LIGHTLY.

POUR IN 1 TEASPOON

MINERAL SPIRITS