Repair

22 311320G

Centerline Component

Removal

1. Perform Pressure Relief Procedure (page

13) and Clean Spray Gun Procedure, page

18.

2. Remove air cap by hand, turning it counter-

clockwise.

3. Remove screen screw assembly. Flush and

place in gun cleaner.

4. Remove check valves. Flush and place in

gun cleaner.

5. Flush screen screw and check valve ports.

6. Remove spring retainer case by firmly

grasping knob of case. Push in and rotate

counterclockwise to remove from air cylin-

der. Pull spring out of air cylinder.

7. Loosen felt wiper retainer 2-3 turns. DO

NOT REMOVE.

8. Remove valving rod. Push back firmly on

piston rod until end of valving rod stop bar

emerges from cylinder.

9. Remove gun block from frame.

10.Unscrew felt wiper assembly from rear of

mixing chamber. Keep rear of mixing cham-

ber in upright position to prevent possible

loss of internal chamber parts. Ensure

brass retaining sleeve is not stuck to felt

wiper. Place wiper assembly in gun

cleaner.

11.Remove mixing chamber. Hold gun block in

one hand with chamber tip pointing into

your palm. Insert mixing chamber knockout

tool into rear of gun block and tap with

hammer until chamber ejects. Place cham-

ber in gun cleaner.

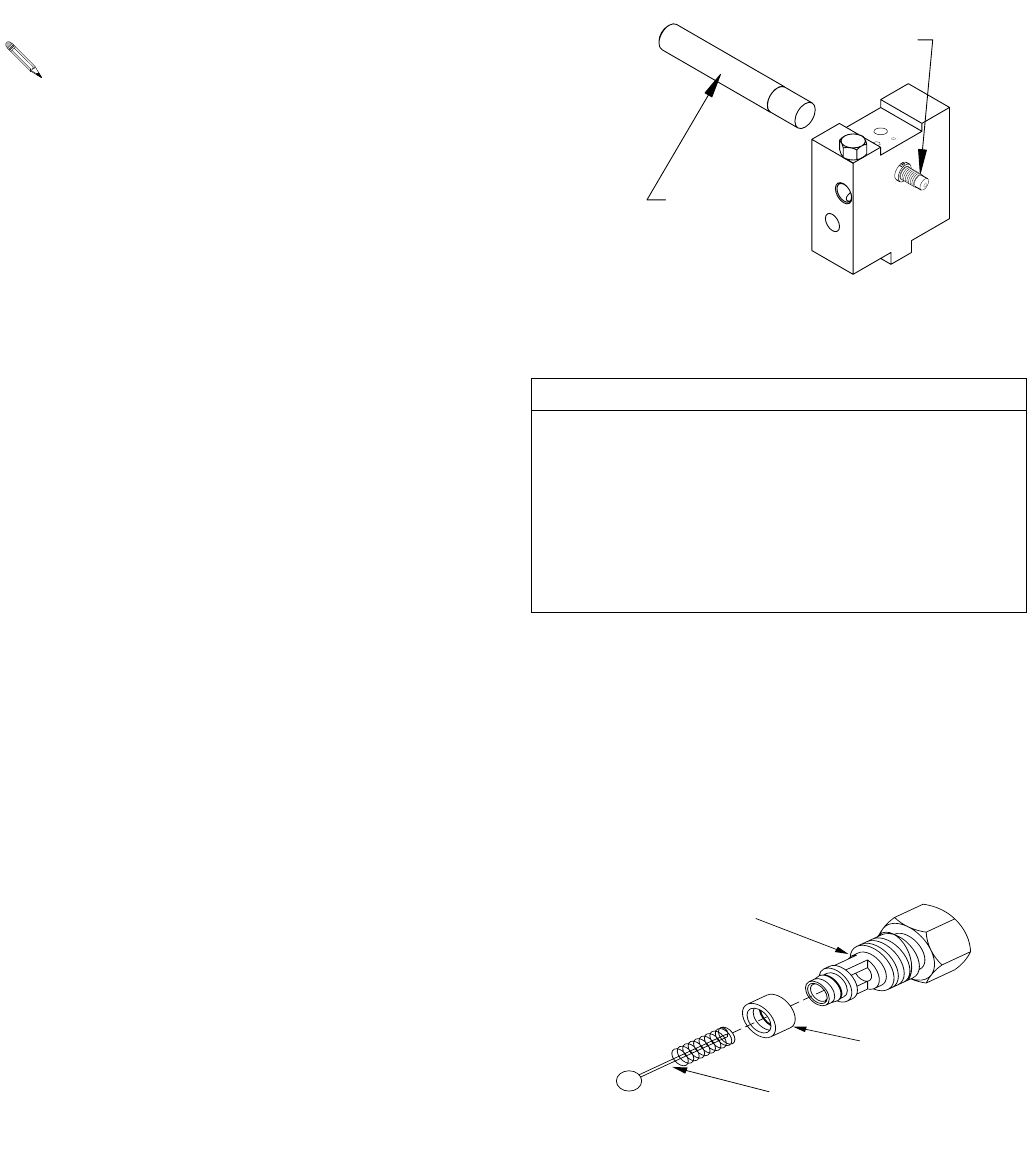

FIG. 22: Mixing Chamber Removal

12.Remove closure screw in top of gun block.

Place screw in gun cleaner and clean entire

gun using appropriate cleanout tools and

brass brushes. Then flush thoroughly with

gun cleaner.

13.Disassemble check valve assemblies.

FIG. 23: Check Valves

Refer to Figure 2 to view centerline com-

ponents.

CAUTION

Matching tapers on mixing chamber and

center hole in gun block are machined to an

exact fit to hold chambers in place and cre-

ate a leak-proof seal. When handling or

cleaning these parts be careful not to dam-

age finish. Do not use metal tools to clean

these parts.

Mixing Chamber

Chamber

Knockout

Tool

Screw

Sleeve

Ball and Spring