Setup

16 313869B

Flush Spray Gun

Before running any paint through the spray

gun:

1. Flush the gun with a solvent that is compat-

ible with the fluid to be sprayed, using the

lowest possible fluid pressure and a

grounded metal container. See Clean and

Flush Gun, page 20.

2. Perform Pressure Relief Procedure,

page 18.

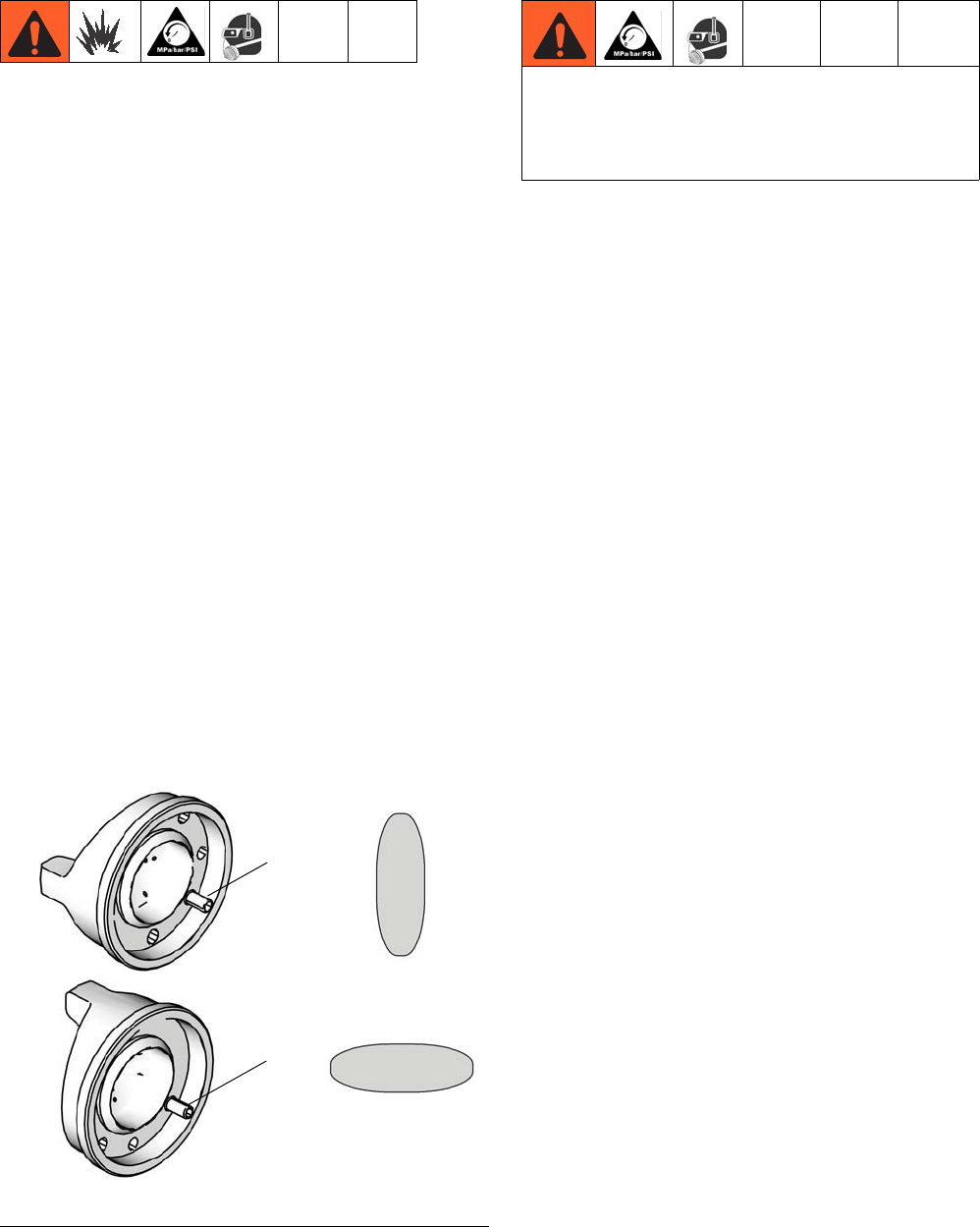

Position Air Cap

Air caps are factory-set with the alignment pin

(A) set to a vertical spray pattern. To change

the air cap to a horizontal spray pattern, use a

1/16 in. hex wrench to unscrew the alignment

pin (A) and relocate it to the horizontal spray

pattern hole. When relocating the pin use low

strength thread locker. Torque to 1.5-2.5 in-lb

(0.2-0.3 N•m). Do not overtighten. Refer to

FIG. 10.

Adjust Spray Pattern

Use the fluid pressure regulator to adjust the

spray gun fluid flow. All models are equipped

with a fluid control knob to make precise fluid

flow adjustments.

Follow these steps to establish the correct fluid

flow and air flow:

1. To achieve desired flow, adjust the fluid flow

using the fluid pressure regulator (L)

installed in the gun fluid line. Typical indus-

trial flow rates will vary with regulator pres-

sures from 5 to 30 psi (34 to 210 kPa,

0.3 to 2.1 bar). If the fluid pressure is too

low at the desired flow rate, install a smaller

nozzle. If the fluid pressure is too high,

install a larger nozzle.

For spray guns equipped with the fluid con-

trol knob, you can make flow rate changes

at the spray gun. Rotate the fluid control

knob clockwise to reduce the flow.

FIG. 10: Position Air Cap

Vertical Pattern

Horizontal Pattern

ti8171a

ti8170a

A

ti8172a

A

Do not exceed 100 psi (0.7 MPa, 7 bar)

maximum fluid and air pressure. Higher

pressures can cause parts to rupture and

result in serious injury.