-34-

G0613/14 Swivel Mast Metal Cutting Bandsaw

The blade guides have a basic factory adjust-

ment, but due to shipping and storage we recom

-

mend that you readjust the blade guides yourself

to ensure the cuts will to be your standards

.

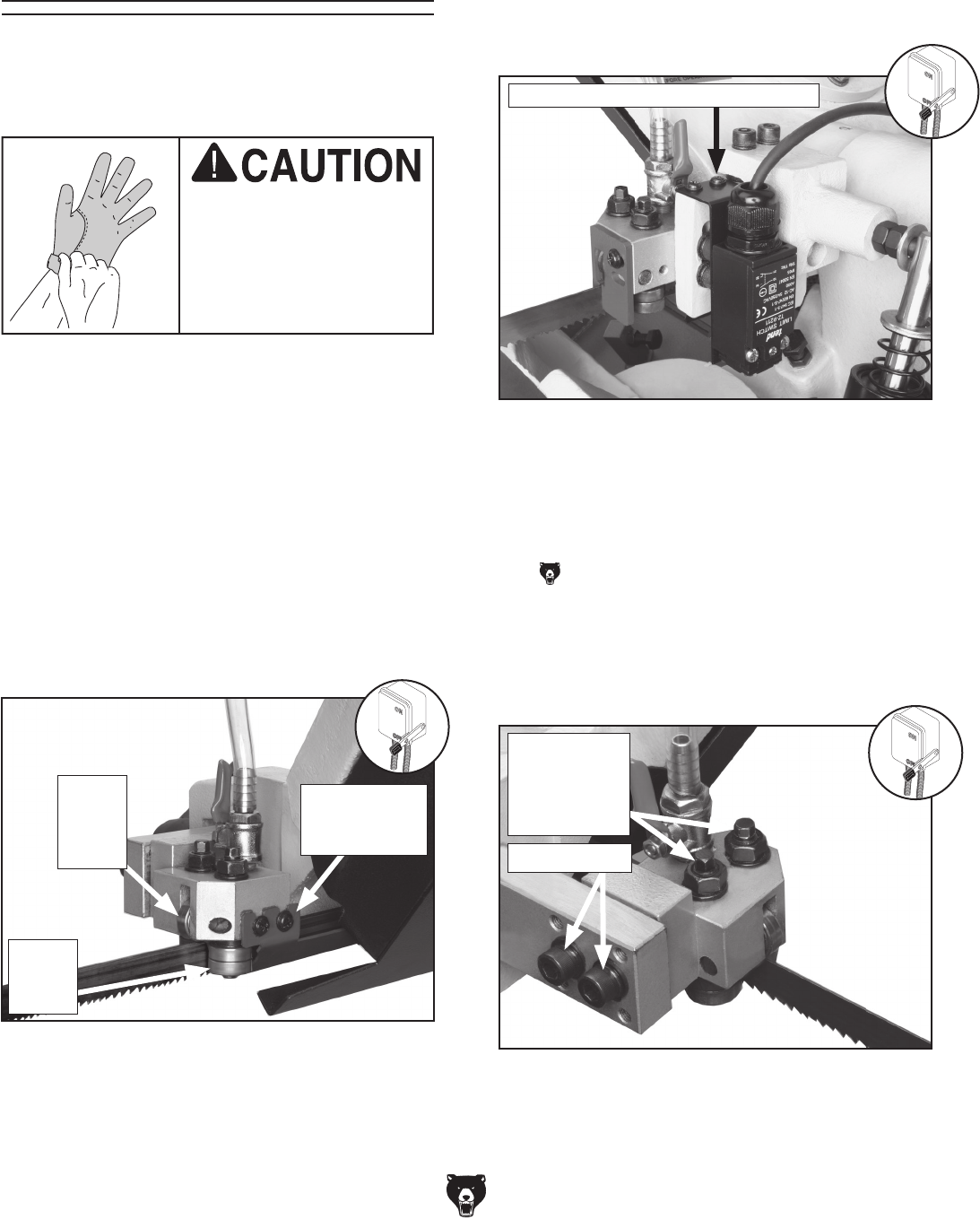

Blade Guides

(G0613)

To adjust the blade guides:

1. Make sure the blade is oiled, tensioned, and

tracking correctly.

2. DISCONNECT THE BANDSAW FROM

POWER!

3. Raise and lock the bow in place and slide the

guides together as close as you can and lock

into place

.

4. Loosen the two cap screws and the blade

guide guard shown in Figure

39.

5. Loosen the cap screws (Figure 41), and

adjust the blade guide housing so t

he back of

the blade

slightly touches the bearing and the

guide housing is not tilted.

Figure 39. Upper blade guide components.

Blade

Guide

Rollers

Upper

Blade

Guide

Roller

Figure 41. Blade guide adjustment locations.

Cap Screws

7. Loosen the 14mm jam nuts and rotate the

7mm hex on top of the bearing eccentrics

(Figure 41), and adjust the bearings against

the side of the blade.

Tip: There should be no gap between the

blade and the bearings.

To set this clearance

to zero without fighting the twist of the blade,

remove the blade guide assemblies, set this

clearance to the blade thickness

, then rein-

stall the blade guide assemblies

.

Blade Guide

Jam Nuts

and

Eccentrics

CUTTING HAZARD!

Blades are sharp! Put

on heavy leather gloves

when handling a blade

or making adjustments

near a blade or cutter

!

6. Tighten the cap screws.

Note: To access the cap screws on the other

blade guide, you will have to remove the two

Phillips head screws

(Figure 40) and move

the limit switch and its bracket out of the

way.

Figure 40. Lower blade guide limit switch.

Limit Switch, Bracket, and Screws

Blade Guide

Guard and

Cap Screws