G0613/14 Swivel Mast Metal Cutting Bandsaw

-37-

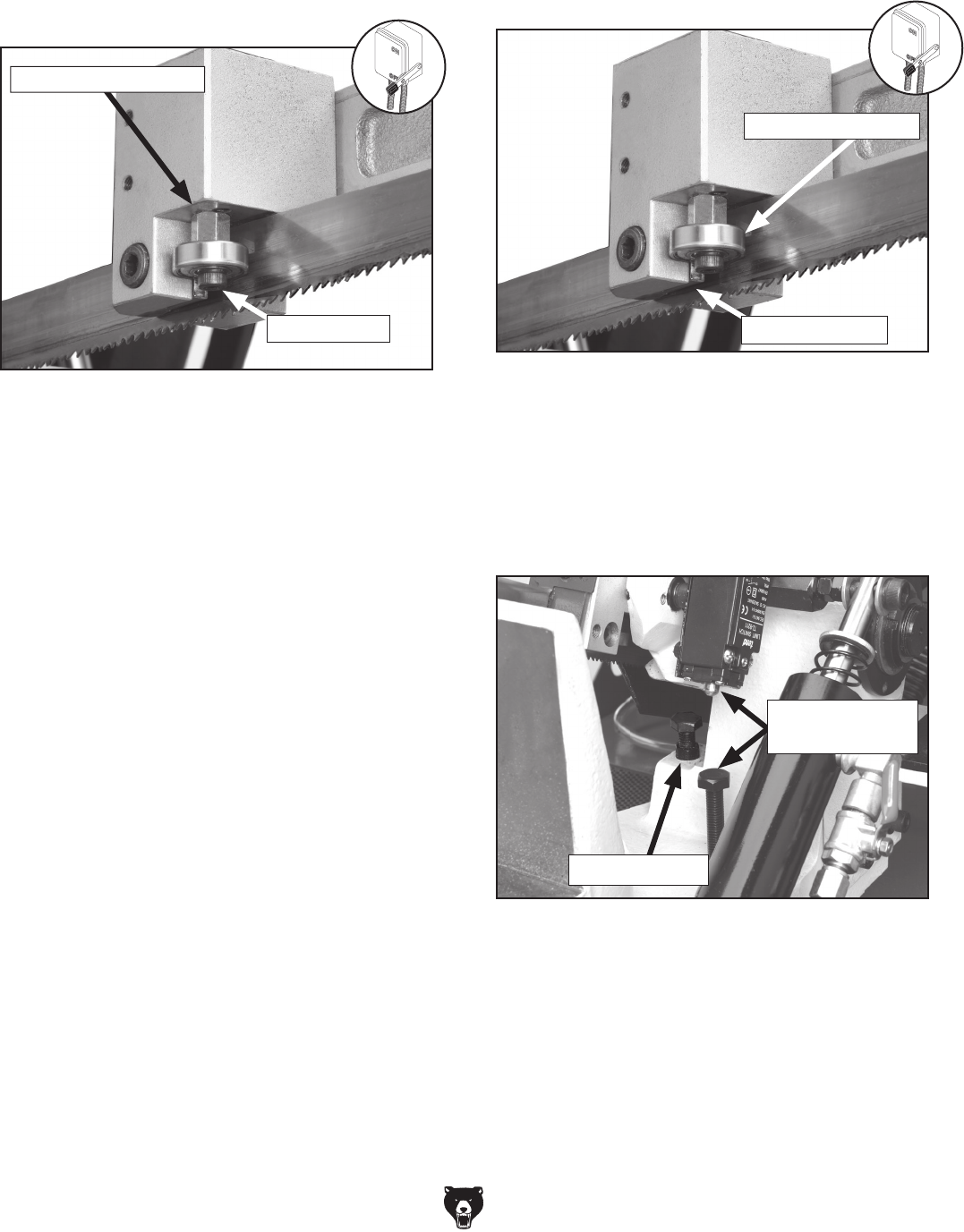

12. When finished with the carbide guide adjust-

ments, make sure the ball bearing guide

(Figure 46) adjustments have not changed.

Re-adjust if required.

Figure 46. Guide types.

Ball Bearing Guide

Carbide Guide

Figure 47. Auto stop.

15. Go to Swivel Stops on Page 38 and com-

plete the steps to make sure the cuts will be

perpendicular to the table.

13. Reinstall the guide guards and the limit switch

and bracket

.

14. Adjust the auto stop bolt and the bow stop

bolt (Figure 47), so the bandsaw motor will

stop when the blade teeth are just below the

vise table surface

.

7. Loosen the cap screw, rotate the 10mm hex

eccentric (Figure 45), and adjust the bear-

ing against the side of the blade so there is

no clearance, but the bearing is not

overloaded.

Figure 45. Upper blade guide adjustments.

10mm Hex Eccentric

Cap Screw

8. Double check bearing adjustments.

9. Adjust the other blade guide.

10. Loosen the carbide guide cap screw and use

the set screw (Figure 43) to set the carbide

guide clearance to zero, but do not tighten

the set screw so the carbide guides pinch the

blade.

10. Tighten the cap screw making sure that when

you tighten it, the carbide guide does not

rotate out of the guide

housing.

11. Adjust the other set of carbide guides.

Limit Switch and

Auto Stop Bolt

Bow Stop Bolt