G0621 Wood/Metal Bandsaw

-19-

A properly tensioned blade is essential for mak-

ing accurate cuts and is a prerequisite for making

many bandsaw adjustments. The blade tension is

adjusted by rotating the blade tension lever.

To tension the bandsaw blade:

1. Make sure you have performed the Test Run

instructions on the previous page and you are

certain that the blade is tracking properly.

2. With the blade tension lever in the down

(engaged) position, adjust the blade tension

until the mark on the blade tension scale

matches the size of blade installed on the

bandsaw.

Note: Because each blade is different and all

blades stretch, this scale can only be consid

-

ered as a general guide.

3. Turn the bandsaw ON.

4. Release the tension one quarter of a turn at a

time. When the bandsaw blade starts to flut

-

ter, stop decreasing the tension.

5. Now, slowly increase the tension until the

blade stops fluttering, then tighten the tension

one more quarter of a turn.

6. Turn the bandsaw OFF and read the tension

gauge. Use the reading as a guide when ten

-

sioning that blade in the future.

Note: Do not rely on this measurement for

long periods of time because the blade will

stretch with use.

NOTICE

To reduce blade stretching, remove the ten-

sion from the blade when not in use.

NOTICE

After blade tension and tracking are set cor-

rectly, properly adjust the upper/lower sup

-

port bearings and guide-block assemblies

into position before operating machine.

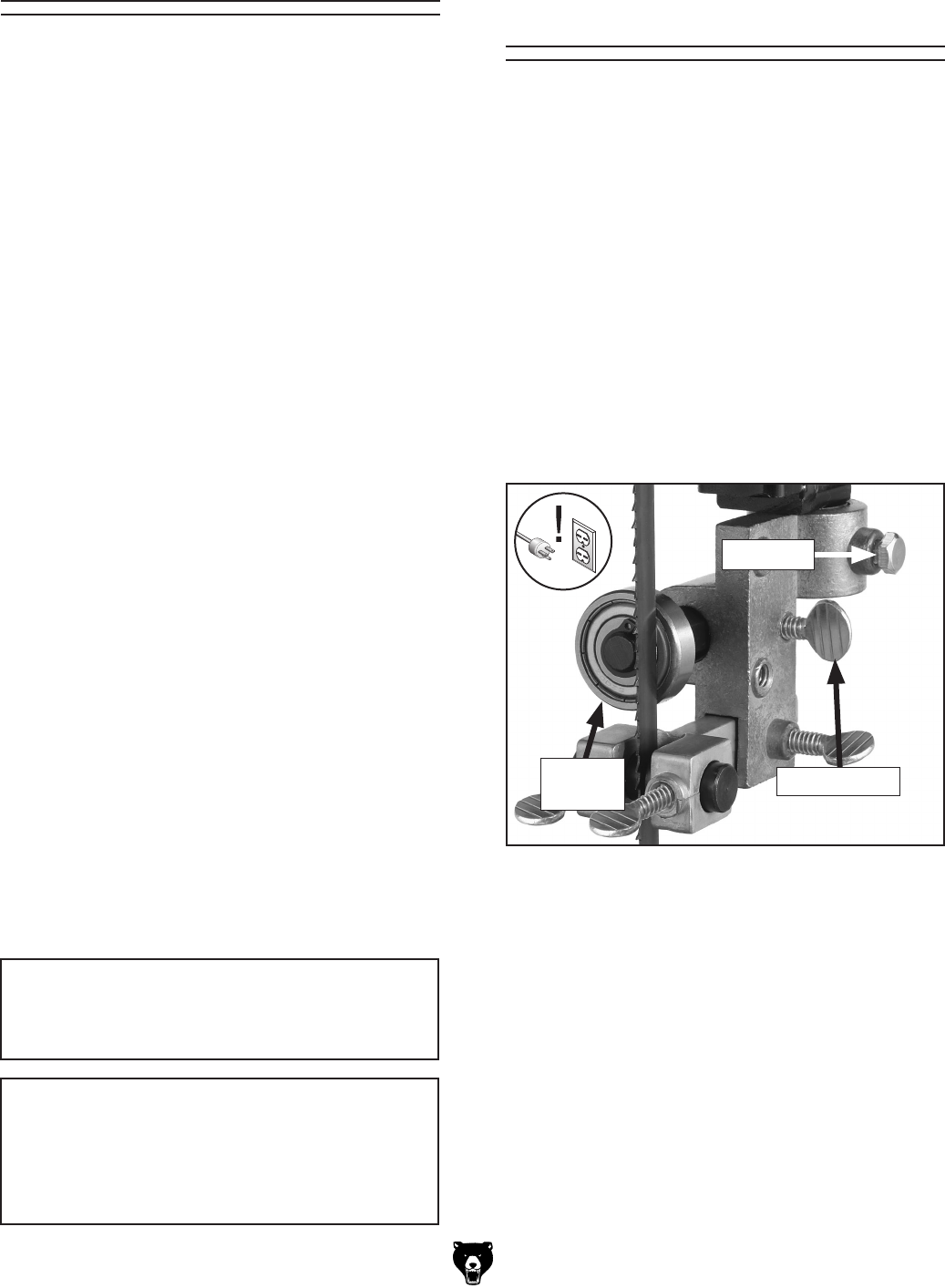

The support bearings are positioned behind the

blade to support it during cutting operations.

Proper adjustment of the support bearings is

an important part of making accurate cuts and

also keeps the blade teeth from hitting the blade

guides during cuts.

To adjust the support bearings:

1. Make sure that the blade is tracking properly

and that it is correctly tensioned.

2. DISCONNECT BANDSAW FROM POWER!

3. Familiarize yourself with the support bearing

controls shown in

Figure 20.

4. Remove the blade guard.

5. Loosen the lock bolt shown in Figure 20.

Tensioning Blade Adjusting Support

Bearings

Figure 20. Support bearing controls.

Thumbscrew

Support

Bearing

Lock Bolt