-30-

G0621 Wood/Metal Bandsaw

Selecting the right blade for the cut requires a

knowledge of various blade characteristics.

Blade Length

Measured by the circumference, blade lengths

are usually unique to the brand of your bandsaw

and the distance between wheels. The Model

G0621 uses 108" long blades. Refer to Page 35

for blade replacements.

Blade Width

Measured from the back of the blade to the tip of

the blade tooth (the widest point), blade width is

often the first consideration given to blade selec

-

tion. Blade width dictates the largest and smallest

curve that can be cut, as well as how accurately it

can cut a straight line.

The Model G0621 uses blades from

1

⁄8" to 1" in

width. Always pick the size of blade that best suits

your application.

• Curve Cutting: Use the chart in Figure 35 to

determine the correct blade for curve cutting.

Determine the smallest radius curve that will

be cut on your workpiece and use the corre

-

sponding blade width.

• Straight Cutting: Use the largest width

blade that you own. Narrow blades can cut

tight curves (a small radius) but are not very

good at cutting straight lines because they

naturally wander (blade lead). Large blades

excel at cutting straight lines and are less

prone to wander.

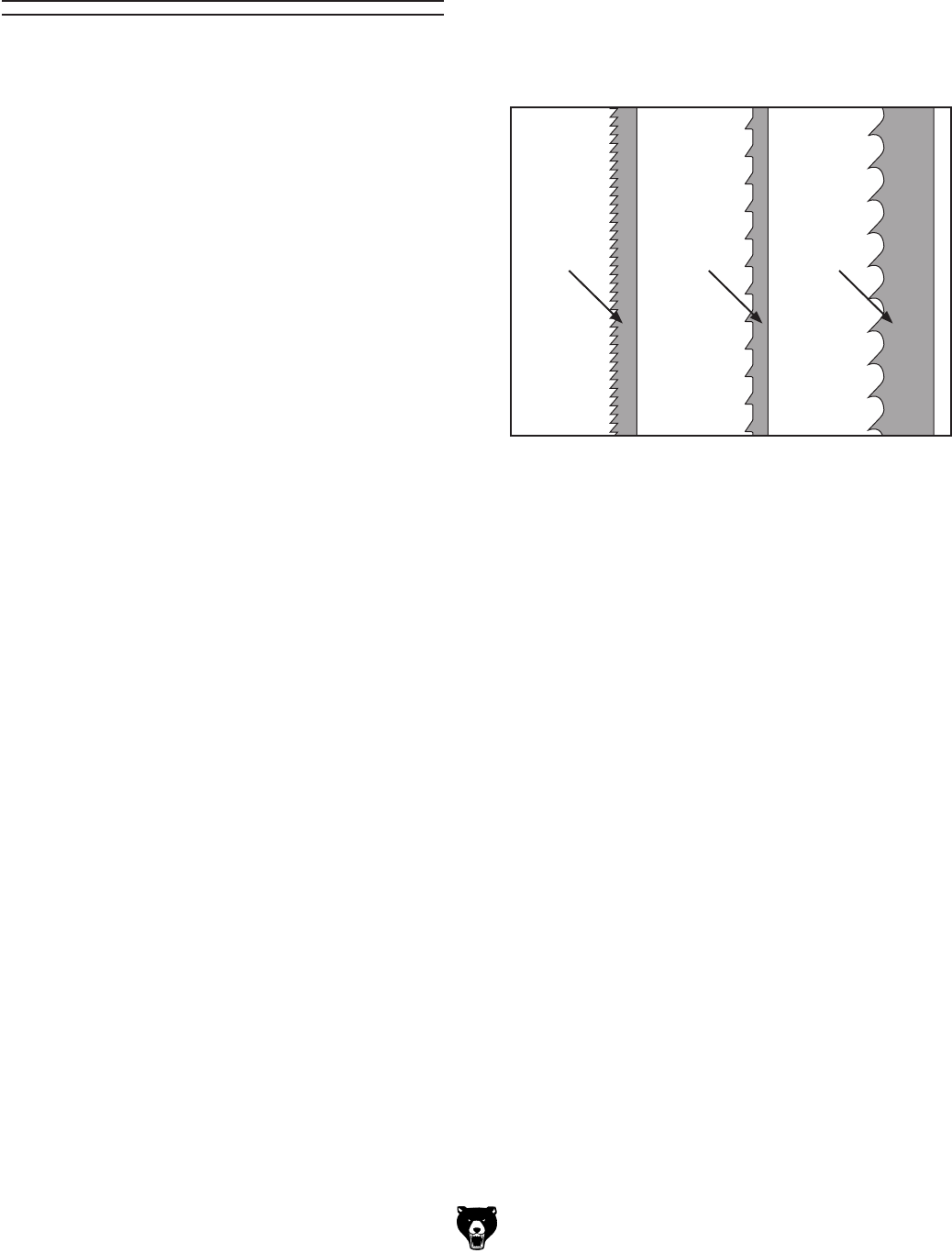

Figure 37. Raker, Skip & Hook tooth styles.

Raker

Skip

Hook

Blade Selection

(Wood Cutting)

Tooth Style

When selecting blades, another option to con-

sider is the shape, gullet size, teeth set and teeth

angle—otherwise known as “Tooth Style."

Figure 37 illustrates the three main categories of

tooth style:

•

Raker: This style is considered to be the

standard because the tooth size and shape

are the same as the tooth gullet. The teeth

on raker blades usually are very numerous,

have no angle, and produce cuts by scrap

-

ing the material; these characteristics result

in very smooth cuts, but do not cut fast and

generate more heat than other types while

cutting.

• Skip: This style is similar to a raker blade

that is missing every other tooth. Because of

the design, skip toothed blades have a much

larger gullet than raker blades, and therefore,

cut faster and generate less heat. However,

these blades also leave a rougher cut than

raker blades.

• Hook: The teeth on this style have a posi-

tive angle (downward) which makes them

dig into the material, and the gullets are usu

-

ally rounded for easier waste removal. These

blades are excellent for the tough demands

of resawing and ripping thick material.