-42-

G0621 Wood/Metal Bandsaw

Wheel alignment, or "Coplanar Tracking," is one

of the easiest ways to ensure you get optimal per

-

formance from your bandsaw. When wheels are

aligned, or coplanar, the bandsaw cuts straighter.

Vibration, heat, and blade wear are also consid

-

erably decreased because the blade is automati

-

cally balanced on the wheel.

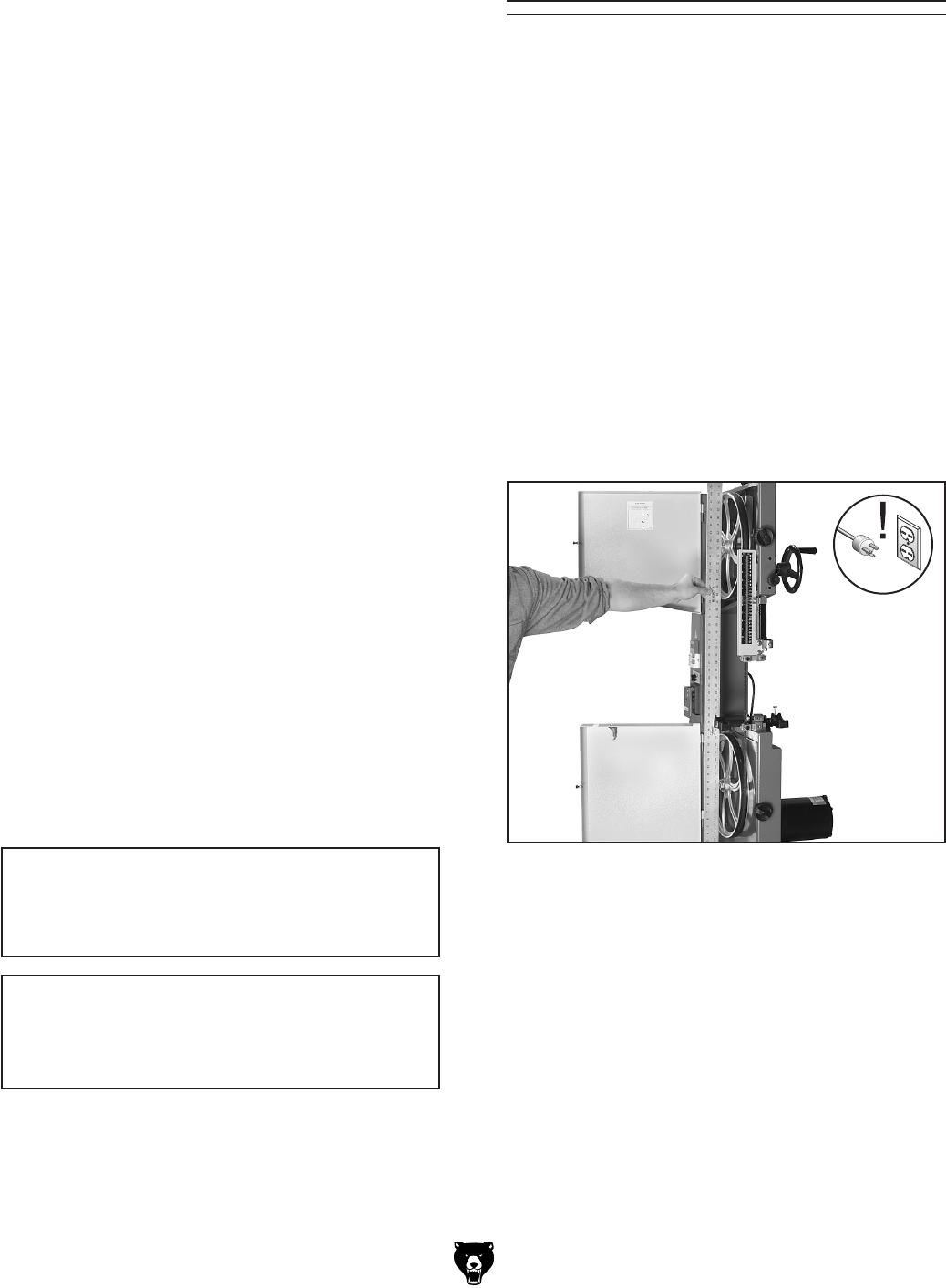

Verifying Upper/Lower Wheels are

Coplanar

1. DISCONNECT BANDSAW FROM POWER!

2. With the blade on and properly tensioned,

hold a straightedge close to the center of

both wheels. Make sure the straightedge

fully extends across the wheels as shown in

Figure 49.

— If the wheels are coplanar, the straightedge

wil touch the top and bottom of the outside

rims on each wheel.

— If the wheels are not coplanar, place

the straightedge on the lower wheel first

(ensuring that it touches both the top and

bottom rim), then adjust the tracking knob

to see how the upper wheel lines up with

the straightedge.

NOTICE

Lead adjustments will change when new

blades are mounted on the saw.

NOTICE

If the table is shifted, the fence will be

affected since it is attached.

3. Clamp the board to the bandsaw table with-

out moving it. Now slide the fence over to

the board so it barely touches one end of the

board.

4. Loosen the two cap screws that mount the

front rail to the table.

5. Place shims between the front rail and the

table as necessary to make the fence parallel

to the edge of the scrap piece.

Note: Shim stock works well for this, but small

pieces of paper can also work in a pinch.

To compensate for lead when making straight

crosscuts with the miter gauge, you will need

to shift the table:

1. Set the miter gauge to 90° and verify that the

gauge body is square to the miter bar, using

a 90° square.

2. On a scrap piece of wood, mark a line that

is perpendicular to the front edge of the

workpiece.

3. Starting where the line begins, cut the board

by pushing it through the blade with the miter

gauge.

4. Loosen the table mounting bolts, and shift the

table to compensate for the blade lead.

5. Repeat Steps 1 & 2 until the blade cuts

straight when wood is pushed through with

the miter gauge.

Wheel Alignment

Figure 49. Checking wheel alignment with a

straightedge.