Non-Through &

Through Cuts

Examples of non-through cuts include dadoes

and rabbets. Non-through cuts have a higher risk

of injury from kickback because the blade guard

must be removed. However, the riving knife MUST

be installed because it still provides some protec-

tion. When making non-through cuts with a dado

blade, do not attempt to cut the full depth in one

pass. Instead, take multiple light passes to reduce

the load on the blade. A dado blade smaller than

10" will require removal of the riving knife, because

the riving knife will be higher than the blade.

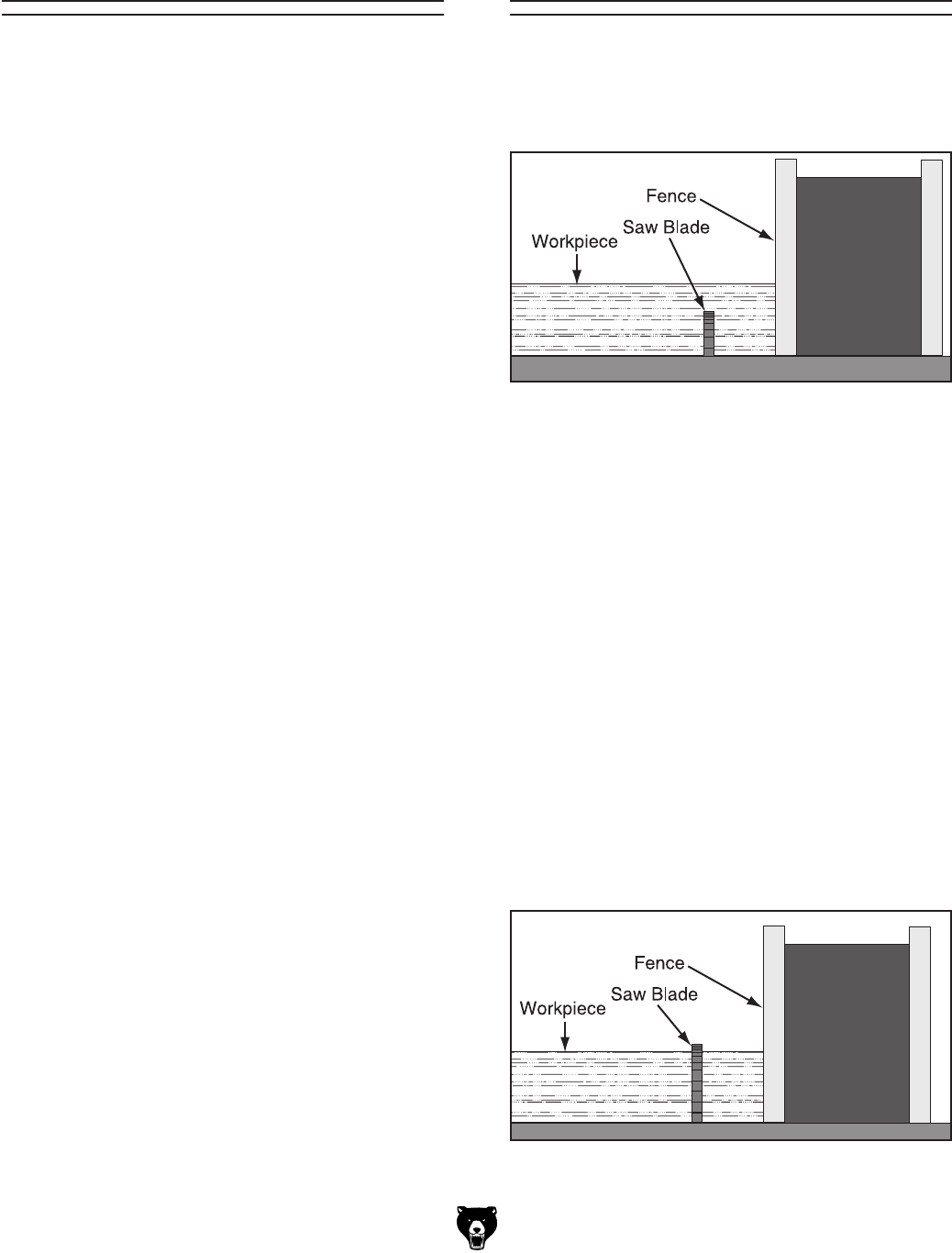

Non-Through Cuts

Figure 35.

A non-through cut is a sawing operation where

the blade does not protrude above the top face of

the wood stock, as shown in the Figure below.

Figure 36.

Through Cuts

A through cut is a sawing operation in which the

workpiece is completely sawn through, as shown

in the Figure below. Examples of through cuts are

rip cuts, cross cuts, miter cuts, and beveled cuts.

The blade guard assembly MUST be used when

performing through cuts.

Workpiece

Inspection

Before cutting, inspect all

workpieces for the following:

• Material Type:Thismachineisintendedfor

cutting natural and man-made wood prod-

ucts, laminate covered wood products, and

someplastics.Cuttingdrywallorcementitious

backerboardcreatesextremelyfinedustand

may reduce the life of the motor bearings.

ThismachineisNOTdesignedtocutmetal,

glass,stone,tile,etc.;cuttingthesematerials

withatablesawgreatlyincreasestheriskof

injuryanddamagetothesaworblade.

• Foreign Objects: Nails, staples, dirt,rocks

and other foreign objectsare often embed-

ded in wood. While cutting, these objects

canbecomedislodgedandhittheoperator,

cause kickback, or break the blade, which

mightthenflyapart.Alwaysvisuallyinspect

yourworkpiecefortheseitems.Iftheycan’t

beremoved,DONOTcuttheworkpiece.

• Large/Loose Knots: Loose knots can

becomedislodged duringthe cuttingopera-

tion. Large knots can cause kickback and

machine damage. Choose workpieces that

donothavelarge/looseknotsorplanahead

toavoidcuttingthroughthem.

• Wet or “Green” Stock:Cuttingwoodwitha

moisturecontentover20%causesunneces-

sarywearontheblades,increasestheriskof

kickback,andyieldspoorresults.

• Excessive Warping:Workpieceswithexces-

sivecupping,bowing,ortwistingaredanger-

ous

to cut because they are unstable and

maymoveunpredictablywhenbeingcut.

• Minor Warping:Slightlycuppedworkpieces

can be safely supported with cupped side

facing the table or fence; however, work-

piecessupportedonthebowedsidewillrock

duringthecut,whichcouldcausekickback.