-12- G1060 22'' Scroll Saw

SECTION 6: OPERATIONS

Once assembly is complete and adjustments are

done to your satisfaction, you are ready to test

the machine.

Turn on the power supply at the main panel.

Press the START button. Make sure that your fin-

ger is poised on the STOP button, just in case

there’s a problem. The scroll saw should run

smoothly, with little or no vibration or rubbing

noises. Strange or unnatural noises should be

investigated and corrected before operating the

machine further.

WARNING: DO NOT attempt to investigate or

adjust the machine while it is running. Wait until

the machine is turned off, unplugged and all

working parts have come to a rest before you do

anything!

If you cannot easily locate the source of an

unusual noise or vibration, feel free to contact our

service department for help.

Your scroll saw can perform a variety of intricate

cuts: straight, curved, bevel, inside, and so on.

The kind of work you produce with it is limited

only by your imagination.

In this section we’ll cover the four basic types of

cuts from which all others are variations. Please

keep in mind that these are standard guidelines;

they are by no means the only correct ways to

use your Scroll Saw. NOTE: Safety Shield is

removed for photographic clarity in this section.

Test Run

Straight Cuts

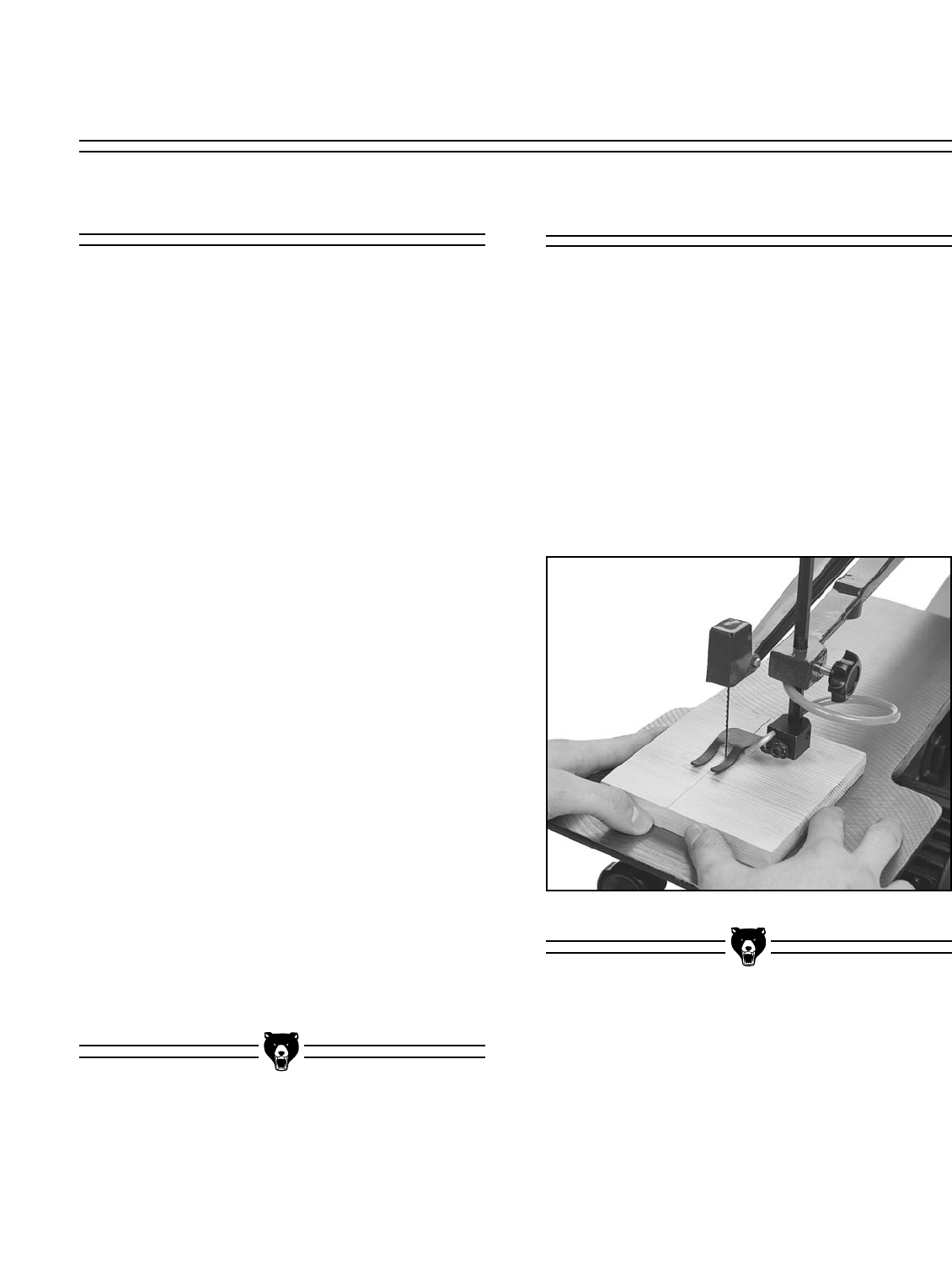

1. Scribe a straight line on your workpiece with

a sharp pencil or scratch awl.

2. Adjust Hold-down Foot so it barely touches

the workpiece.

3. Turn power on. Allow motor to get up to

speed and push workpiece slowly and

steadily into the blade, keeping your hands

to either side of the cutting line. Make sure

the blade is cutting to the waste side of the

line. Figure 9.

Figure 9.