G1060 22'' Scroll Saw -15-

SECTION 7: MAINTENANCE

Lubrication

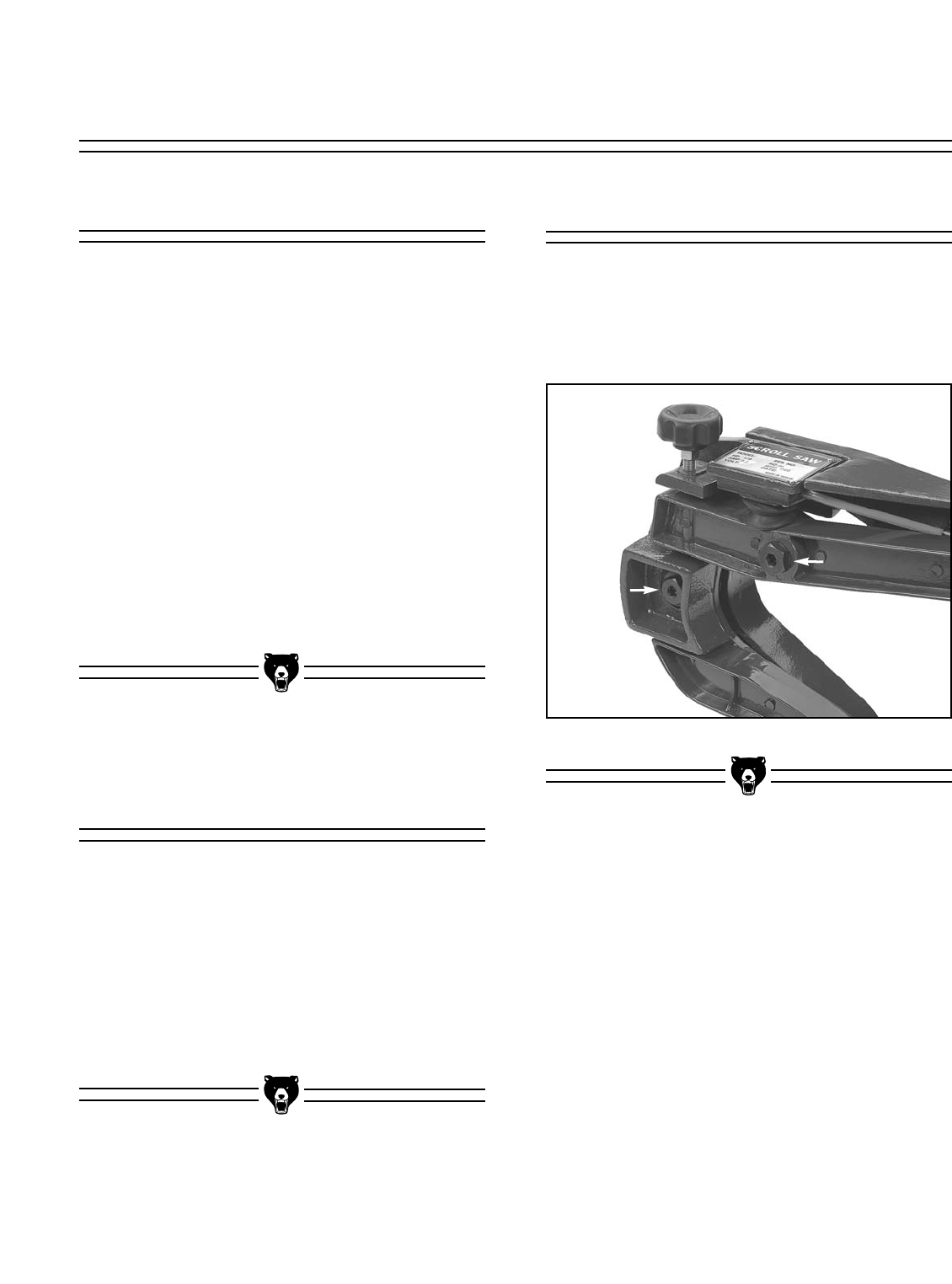

Lubricate the upper and lower guide arm bush-

ings once a month. Light machine oil will be ade-

quate. Damage to the motor may result if the

bushings are allowed to run dry.

Regular periodic maintenance on your Model

G1060 Scroll Saw will ensure its optimum perfor-

mance. Make a habit of inspecting your scroll saw

each time you use it. Check for the following con-

ditions and repair or replace when necessary.

Caution: Always perform any maintenance with

the power off and the machine unplugged.

1. Loose bolts.

2. Worn switch.

3. Worn or damaged cords and plugs.

4. Any other condition that could hamper the

safe operation of this machine.

General

Working Table

The working table can be kept slippery and rust-

free with regular applications of talcum powder.

Rub the powder into the table tops with either a

felt brick (i.e.-common chalk board eraser) or a

chamois cloth.

We do not recommend wax or paraffin; eventual-

ly, the buildup will impede the smooth movement

of your lumber over the table surfaces.

Figure 14.