G1148 15" Bandsaw

-11- G1148 15" Bandsaw

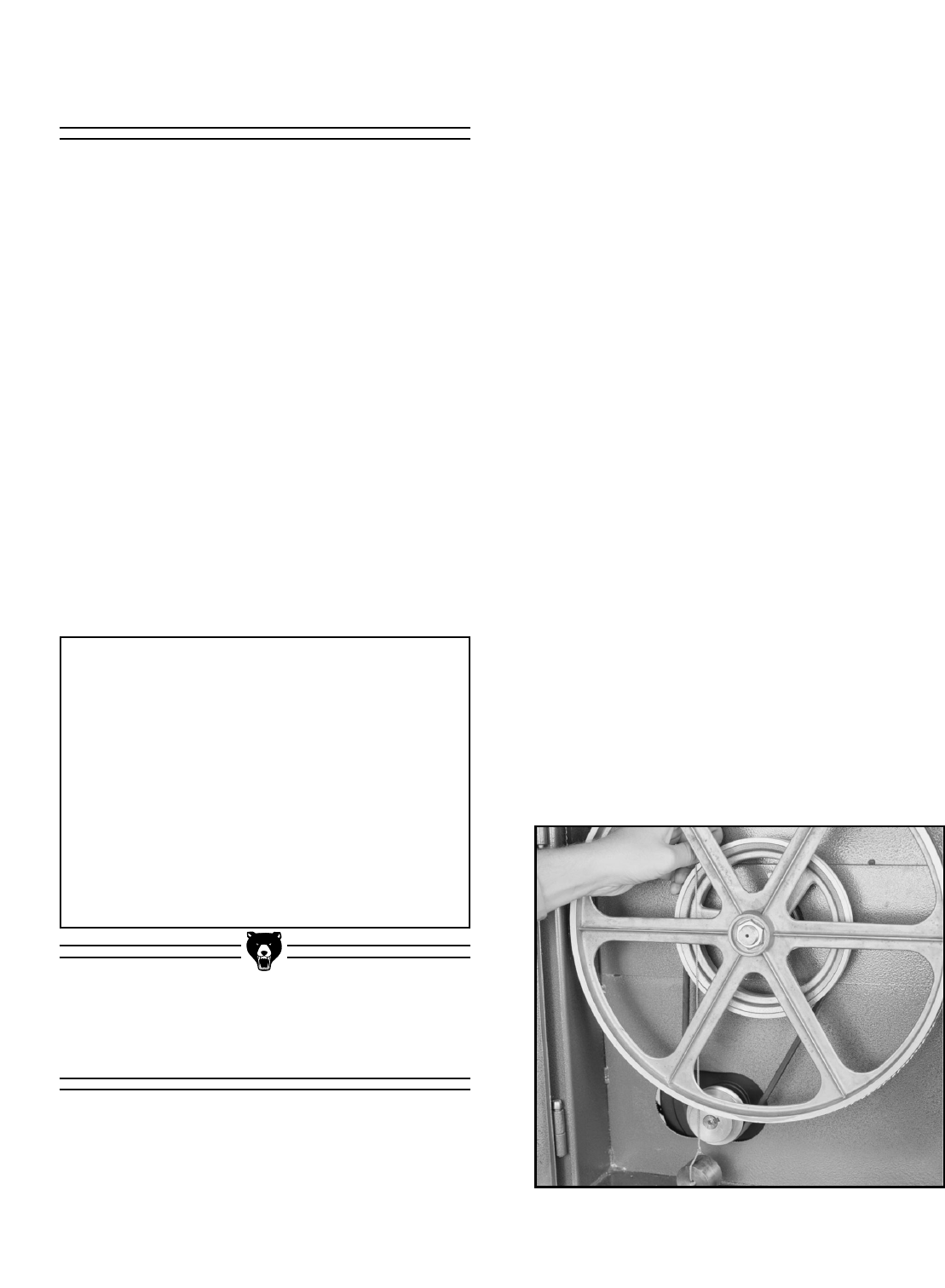

Figure 4. Adjusting pulley alignment

Motor, Pulley, V-Belt

Bandsaw Unit

This bandsaw is relatively heavy and awkward to

handle. We strongly recommend that you get

assistance. The bandsaw unit is also very unsta-

ble until it is permanently mounted to the stand.

Use care so the bandsaw unit does not tip.

1. Place the bandsaw on the stand with assis-

tance and align the four (4) holes in the

base over the four (4) mounting holes in the

stand.

2. Loosely secure the bandsaw base to the

stand with the four (4)

3

/8" - 16 x 3" hex

bolts, nuts, and washers provided.

3. Wiggle the bandsaw back and forth on the

stand to ensure that the bandsaw stand is

seated properly. Ensure that the stand is

symmetrical when viewed from the front

and the side. Tighten fasteners securely.

NOTICE

Ensure that the Model G1148 is located on a

flat, level surface.This will maximize the sta-

bility of the machine and ensure that adjust-

ments are accurate. For conditions where

permanent mounting is possible, you may

consider adding L-brackets at the bottom of

the stand to enable you to bolt the machine

to your shop’s floor. This type of mounting

will minimize vibration and provide a more

stable work environment.

2. Insert the 4 carriage bolts through the slots.

Use washers on the underside. Finger tight-

en the nuts for now.

3. Slip the V-Belt into the grooves of the wheel

and motor pulleys. Be sure grooves you

choose are aligned. For general woodwork-

ing, use fastest blade speed (i.e. the small-

er diameter wheel pulley groove combined

with the larger diameter motor pulley

groove).

NOTE: For resawing and cutting operations with

wider blades, use the slow speed (i.e. the larger

diameter wheel pulley groove combined with the

smaller diameter motor pulley groove). When

using the slow speed, do not feed stock too fast.

This will cause possible blade breakage, stalling,

and extremely poor cuts.

4. Check for proper pulley alignment by plac-

ing a plumb line on the outside edge of the

upper pulley so that it overlaps the motor

pulley. If the line touches both pulleys even-

ly, the pulleys are aligned. If the line does

not touch both pulleys evenly, wiggle the

motor until the pulleys come into alignment.

If proper alignment is still not attained,

loosen the setscrew (#62) on the motor pul-

ley and push the pulley in or out to achieve

proper alignment. Remember to retighten

the setscrew when finished. See Figure 4.

1. Align the mounting slots on the motor over

the mounting slots on the base of the band-

saw. Be sure that the V-Belt (#28), which is

already installed over the wheel pulley

(#30), fits over the motor pulley (#29).