G1495 Heavy-Duty Wood Lathe

-13-

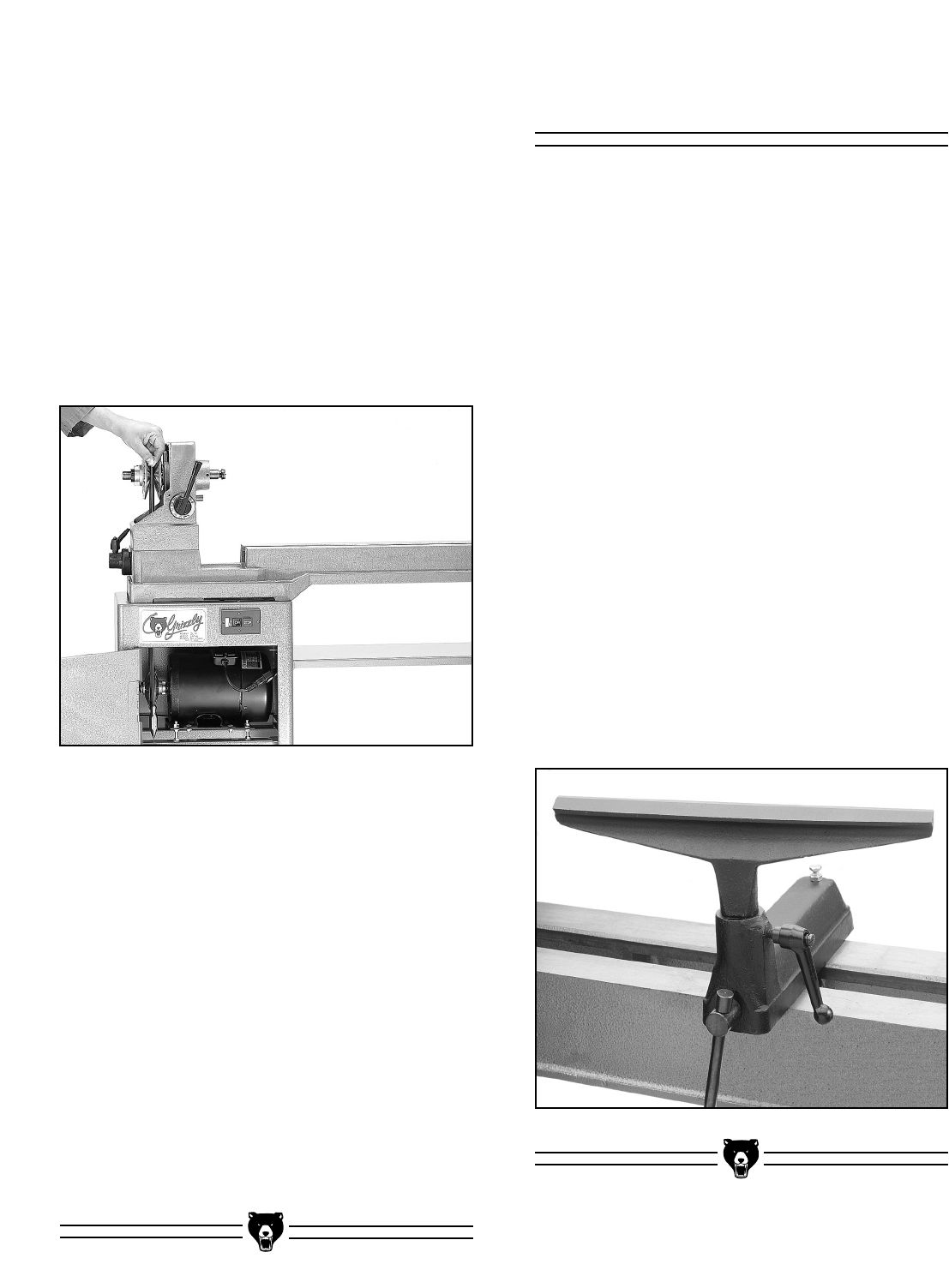

Tool Rest

Figure 9. Mounting the tool rest.

The tool rest is equipped with a cam-action

clamping system to secure it to the lathe bed.

When the lever is thrown, a locking plate lifts up

and secures the tool rest to the bed. See Figure

9. To install the tool rest assembly:

1. Remove the large hex nut and lock plate

from the bottom of the tool rest assembly.

2. Set the tool rest assembly on the lathe bed

with the clamp stud between the bed slot.

3. Set the tool rest lock handle so it is pointing

down. Re-install the lock plate and thread

the hex nut back onto the stud until it bot-

toms out.

4. Lift the lock handle approximately 90˚ and

tighten the hex nut

1

⁄2 to

2

⁄3 of a turn more.

5. Turn the tool rest lock handle until it locks

the tool rest down onto the bed. You may

need to adjust the Hex Nut in small incre-

ments to fine tune how the tool rest assem-

bly locks down onto the bed.

Figure 8. Using plumb bob for pulley alignment.

8. To align the pulleys, set the speed control

lever mid-way between high and low so the

upper and lower pulleys are spread

approximately the same amount. Ensure

that the lathe is sitting level. Use a plumb

bob to check the side of the pulleys in rela-

tion to each other. See Figure 8.

If the pulleys are not in alignment, loosen

the motor mounting bolts and move the

motor on its mounting plate. The lathe

assembly can also be moved slightly to

achieve alignment, by loosening the bolts

installed in Step 5.

9. Tighten the motor adjusting nuts so there

is constant pressure on the V-belt from the

lower motor pulley. Ensure that the motor is

level and the pulleys are parallel with each

other. Once the V-belt is in position,

change speeds only with the motor run-

ning and the headstock cover in place. If

speed changes are necessary for adjust-

ment or testing, unplug the machine and

rotate the pulleys by hand while moving

the speed lever. Never move the speed

lever without rotating the spindle as the

belt can become jammed or the movable

pulley can be damaged.

10. At this point tighten all the bolts on the

stand. Put the headstock cover plate back

into place and secure.