G1495 Heavy-Duty Wood Lathe

-19-

Figure 21. Outboard tool rest.

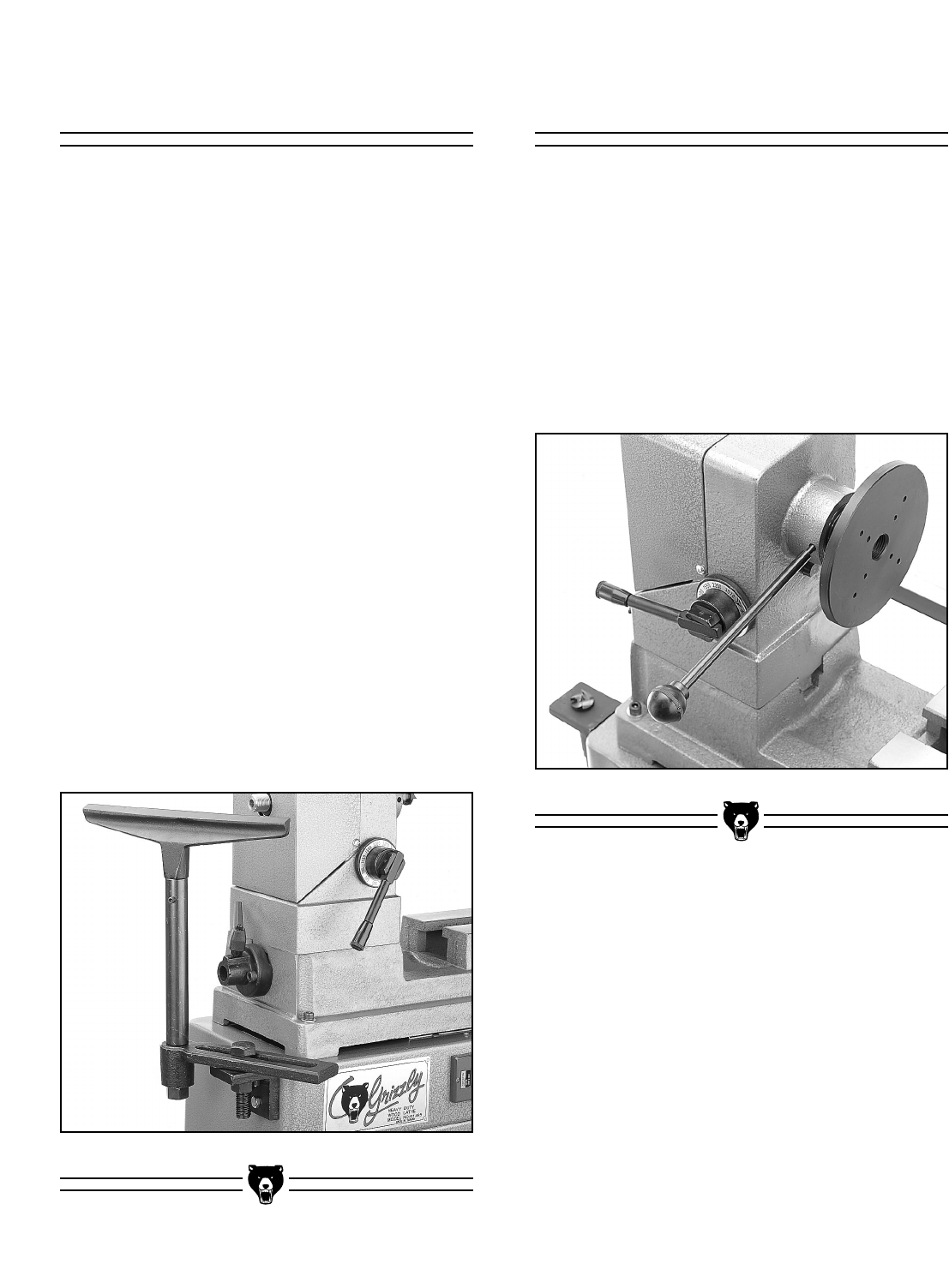

Figure 22. Knockout bar for removal.

Outboard Tool Rest Accessory Removal

The outboard side of the headstock can be used

for faceplate turning when the diameter of the

stock exceeds what can be handled on the

inboard side. The range of diameters suitable for

outboard turning is from 14'' to a maximum of

19''. Outboard turning will require an accessory

faceplate which is available from Grizzly.

Outboard turning should always be done with the

tool rest installed:

1. Fasten the L-shaped bracket to the cabinet

stand with the two (2)

5

⁄16'' - 18 x 1'' bolts

provided and tighten with a 12mm wrench.

2. Attach the tool rest support to the bracket

with the

3

⁄4'' - 10 x 2

1

⁄2'' bolt and nut as

shown in Figure 21 This is hand-tightened

only to allow movement.

3. Insert the threaded end of the tool rest post

into the cast boss and secure with the

3

⁄4''

hex nut. This also is only hand-tightened.

4. The tool rest can now be placed into the

end of the support post and secured with

the setscrew.

To remove accessories such as faceplates, sand-

ing discs or the drum/flap sander from the head-

stock spindle, insert the knockout bar into the

hole in the headstock near the inboard spindle.

Turn the spindle by hand until the bar engages

one of the indexing holes, which will lock the spin-

dle in position. While holding the knockout bar,

rotate the accessory counterclockwise if mounted

inboard, or counterclockwise if mounted on the

outboard side. See Figure 22.