G1495 Heavy-Duty Wood

-23-

-23-

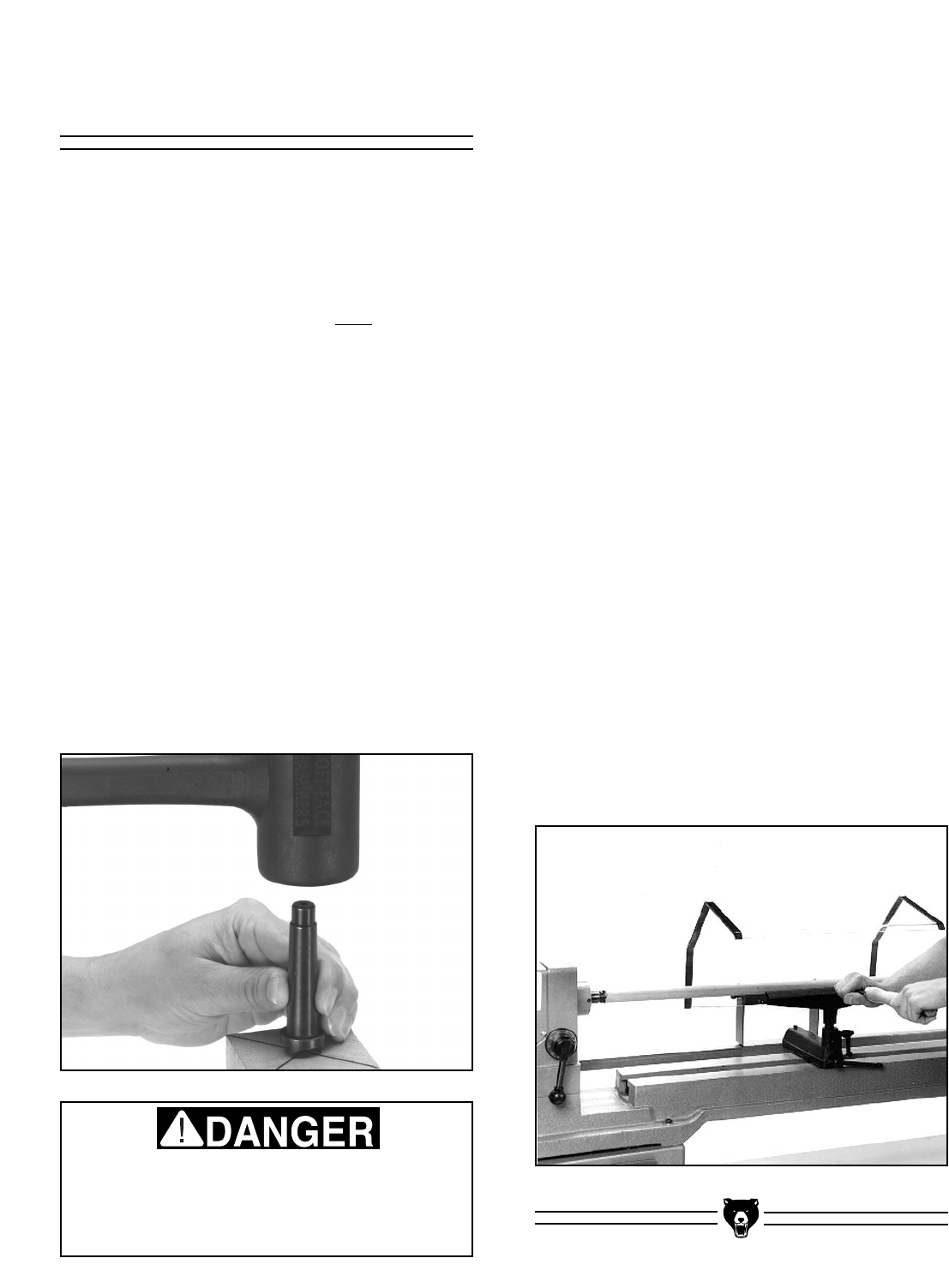

Figure 26. Typical spindle turning setup.

3. With the spur center firmly attached to the

workpiece, insert the spur center into the

headstock spindle.

4. While supporting the free end of the work-

piece in your hand, loosen the tailstock

locking lever and slide the tailstock assem-

bly close to the end of the workpiece and

lock into place.

5. Line up the point of the live center with the

workpiece center. Turn the hand wheel to

press the center into the workpiece. Do not

press too tightly or the bearings will bind

and may overheat. Too loose, however, and

the workpiece will not be properly seated

and may spin off when the lathe is started.

Lock the spindle nose in place with the

locking lever. Make certain no more than 2''

of the spindle is extended.

6. Adjust the tool rest as close to the work-

piece as possible without actually coming in

contact with the workpiece. Test by hand

turning the workpiece before turning lathe

on. Ensure that the lathe chisel is fully sup-

ported by the tool rest. Support the lathe

chisel on the tool rest with one hand, while

controlling the chisel with the other hand.

See Figure 26.

7. Cycle the lathe on and off rapidly to ensure

the workpiece is firmly seated.

Spindle turning is the most common type of work

done with a wood lathe. It involves turning a work-

piece between two centers and removing stock to

achieve a specific contour. To mount a workpiece

between centers:

1. Locate the center point on both

ends of the

workpiece. This can be done by carefully

drawing diagonal lines from corner to cor-

ner.The point of intersection is the center of

the work. Or if the workpiece is somewhat

irregular, there are center finding devices

available which will aid in this step.

2. Hold the workpiece vertically and support it

on a solid surface. Line up the spur center

with the center of the workpiece. Drive the

spur center into the stock about

1

⁄4'' using a

dead blow hammer. See Figure 25. Be

careful not to split the workpiece.Wood with

splits along the grain may fly off the lathe

during operation. For dense wood, drill a

hole for the center and score lines with a

saw blade for the spurs.

Spindle Turning

Make certain the centers at both ends are

firmly seated. Failure to do so can allow the

workpiece to spin off of the lathe. Serious

personal injury may occur.

Figure 25. Seating the spur center.