G1495 Heavy-Duty Wood Lathe

G1495 Heavy-Duty Wood Lathe

Figure 14. Pneumatic drum and flap sander.

Pneumatic Drum and Flap Sander

The drum and the flap wheel attachment mount

onto the mandrel provided. See Figure 14 for

proper installation.

1. First slide the flap wheel over the end of the

mandrel and position it against the

machined land.

2. The drum sander screws onto the threaded

end of the mandrel. Remember both the

mandrel and the spindle are left-hand

threads. The drum sander should be inflat-

ed to approximately 10 PSI using a bicycle

pump or other low pressure inflation device.

Do not over-inflate.

Spur Center

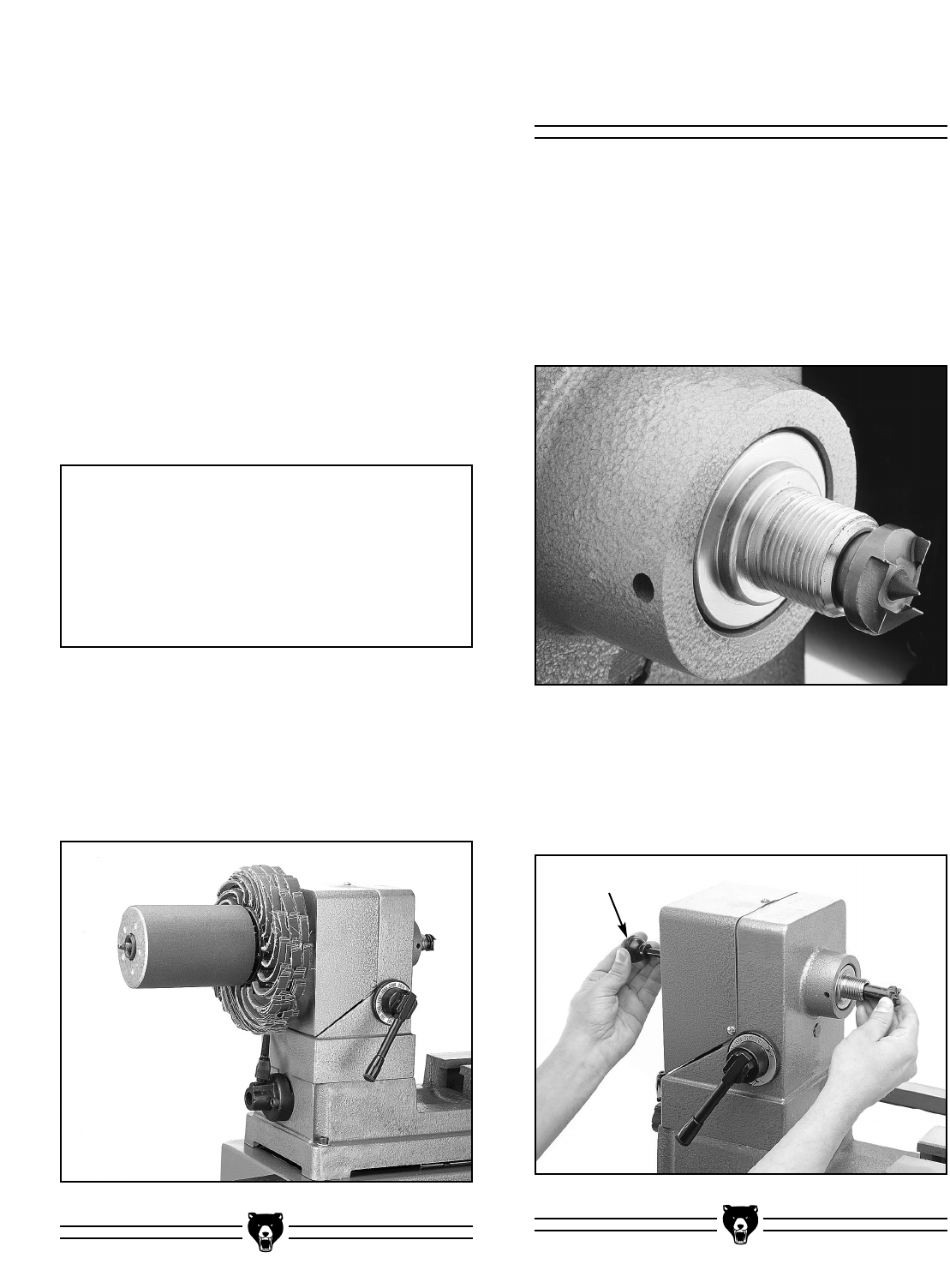

Figure 15. Spur center in headstock spindle.

The G1495 is supplied with a #2 Morse taper four

tine spur center for use when turning. The spur

center is used in conjunction with the tailstock live

center. Install the spur center by inserting into the

hole in the inboard spindle. Figure 15. See

Section 5: Operations, Spindle Turning section for

complete detail on how to properly seat the spur

center.

To remove, insert the knockout bar provided into

the outboard spindle and tap with the palm of

your hand while carefully holding onto the spur

center with your other hand. Figure 16.

Figure 16. Using knockout bar to remove center.

Knockout bar

NOTICE

Do not use a compressor to inflate the

pneumatic sanding drum, it is too easy to

over-inflate. Use a hand-operated pump

only, and check the inflation pressure with a

suitable gauge.

3. These attachments must both be mounted

on the spindle at the same time, regardless

of whether both will be used. The flap

sander attachment helps to provide rigidity

to the mandrel and drum sander when they

are installed together.