-18- G4186Z 18" Bandsaw

Guide Blocks - The guide blocks ensure that

the blade is not pushed too far laterally. To

adjust the guide blocks, loosen the thumb-

screws that secure the guide block shafts.

Adjust them evenly so that the front of the

blocks are

1

/64" behind the gullet line of the

blade. Tighten these thumbscrews. Now

loosen the guide block thumbscrews. The

ideal distance between the blade and each

guide block is .004". This measurement is

approximately the same as the thickness of a

piece of paper or a dollar bill. For a quick

gauge, fold a dollar bill in half, slide it over the

blade so each half covers each side of the

blade. Set the blade guides so each one

touches the dollar bill. Be careful not to move

the blade in either direction while you are per-

forming this adjustment. Tighten the blade

guides. The result of this adjustment should

leave a .004" distance between the blade and

each of the blade guides.

LOWER GUIDES

Adjustments for the lower guides are identical to

those for the upper guides, except that the bear-

ing and guide block positioning is controlled by

setscrews. Use Figure 17 to identify the lower

guide assembly components.

Blade Guides

Whenever changing a blade or adjusting tension

and tracking, the upper and lower blade support

bearings and guide blocks must be re-adjusted.

Always adjust the assemblies away from the

blade before installing a new blade or making

blade tracking adjustments. After blade tension

and tracking are set correctly, re-adjust the upper

and lower support bearings and the guide block

assemblies into position. See Figures 16 and 17

for locations.

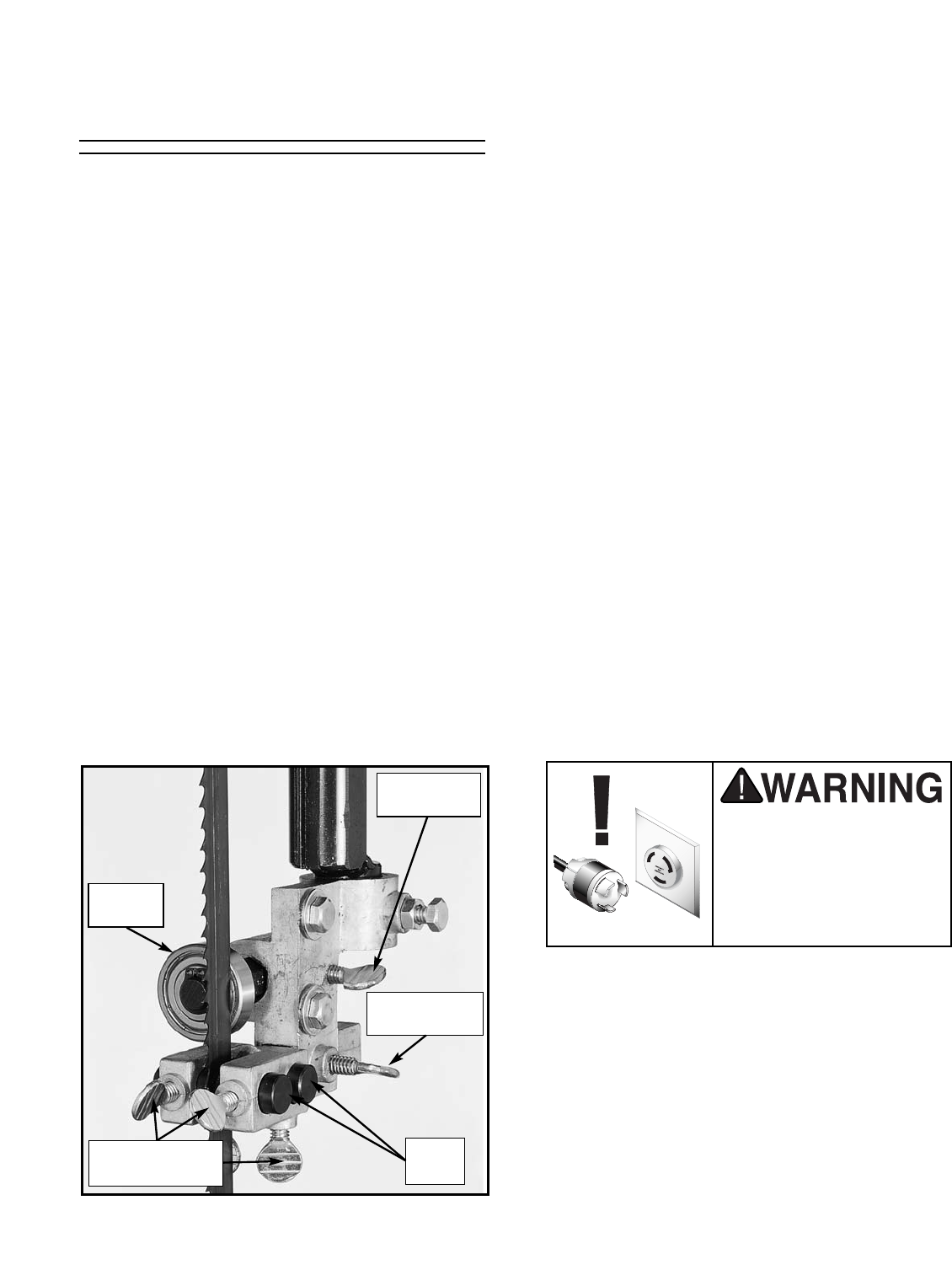

Guide

Blocks

Support

Bearing

Guide Bracket

Thumbscrew

Bearing

Thumbscrew

Guide Block

Thumbscrews

Figure 16. Upper guide adjustments.

UPPER GUIDES

Adjustment of the upper guides is a two-part pro-

cedure, consisting of adjustments to both the

support bearings and the guide blocks.

Support Bearings - The support bearing runs

against the back edge of the blade to keep it

from being pushed out of position by the

advancing workpiece. To adjust the support

bearing, loosen the thumbscrews securing the

support bearing shaft. Push or pull the shaft so

that the upper support bearing is within

1

/64" of

the back edge of the blade. Retighten the

thumbscrews.

Disconnect power to the

machine when perform-

ing any adjustments or

maintenance. Failure to

do this may result in seri-

ous personal injury.