<.'). &'m(,7Zai9g^kZ<Ve7ZYAVi]Z

"'("

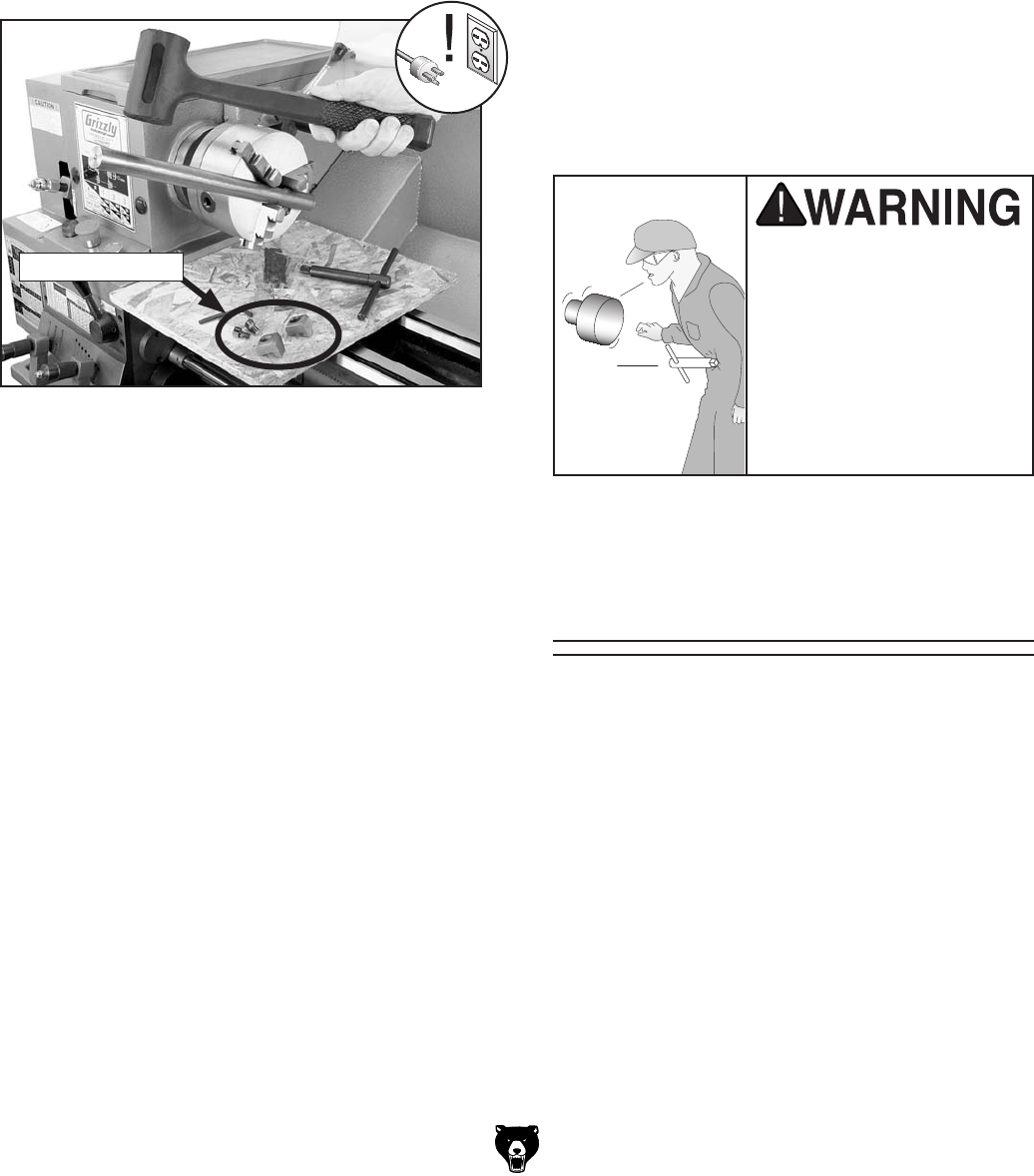

5. A^\]ianiVei]ZWgZV`ZgWVgl^i]i]ZYZVYWadl

]VbbZg id addhZc i]Z X]jX` dg [VXZeaViZ

XdjciZgXadX`l^hZ[gdbi]Zhe^cYaZi]gZVYh#

·>[ gZbdk^c\ V X]jX`! deZc i]Z _Vlh VcY

ha^YZi]ZWgZV`ZgWVgWZilZZci]Z_Vlh!Vh

h]dlc^cFigure 24#

·>[gZbdk^c\i]Z[VXZeaViZ!bdjciXaVbehdc

i]Z[VXZeaViZVcYjhZi]ZWgZV`ZgWVg^cV

h^b^aVgbVccZg#

Figure 24.AddhZc^c\i]ZX]jX`[gdbi]Zhe^cYaZ

i]gZVYh#

He^cYaZ8aVbeh

6. 8VgZ[jaanjci]gZVYVcYgZbdkZi]ZX]jX`dg

[VXZeaViZ XdjciZgXadX`l^hZ[gdb i]Zhe^cYaZ

i]gZVYh#

Mounting a Chuck or Faceplate

1. 9>H8DCC:8IA6I=:;GDBEDL:G

2. AVnVX]jX`XgVYaZdgVaVnZgd[eanlddYdkZg

i]ZWZYlVnhidgZYjXZi]Zg^h`d[^c_jgnVcY

id egdiZXi i]Z egZX^h^dc \gdjcY hjg[VXZh d[

i]ZWZYlVnh#

3. 8aZVcYZWg^h[gdbi]Zi]gZVYhd[i]Zhe^cYaZ

VcYX]jX`dg[VXZeaViZ!i]ZcVeeanVi]^c[^ab

d[a^\]ibVX]^cZd^a#

4. 8VgZ[jaanVcYhadlangdiViZi]ZX]jX`dg[VXZ"

eaViZXadX`l^hZdcidi]Zhe^cYaZjci^andj[ZZa

gZh^hiVcXZ#

5. GdiViZi]Z X]jX`dg [VXZeaViZXdjciZgXadX`"

l^hZ V

&

¿) ijgc! i]Zc fj^X`an gdiViZ ^i WVX`

XadX`l^hZidhZVii]Zi]gZVYh#

Note: Attempting to overtighten the chuck

or faceplate will make removal difficult and

could damage the threads.

6. ;^gban^chiVaaWdi]he^cYaZXaVbehdci]ZWVX`

d[i]ZX]jX`dg[VXZeaViZ#

Note: Make sure the spindle clamp tangs

properly fit into the spindle groove before

tightening the set screw (see Figure 22#

7. GZbdkZi]ZX]jX`XgVYaZdgeanlddYVcYVcn

iddahjhZYWZ[dgZhiVgi^c\i]ZaVi]Z#

Make sure the chuck or

faceplate is firmly secure

on the spindle and remove

the chuck key. Object

thrown from the lathe

could cause serious per-

sonal injury or death to

the operator or bystand-

ers.

Mounting a

Workpiece

Ine^XVaan!Vldg`e^ZXZ^hbdjciZY^cV("_Vl

X]jX`! V )"_Vl X]jX`! V [VXZeaViZ! dg WZilZZc

XZciZgh# I]ZgZ VgZ! ]dlZkZg! cjbZgdjh di]Zg

bZi]dYh d[ldg`e^ZXZ bdjci^c\ [dg V aVi]Z i]Vi

VgZWZndcYi]ZhXdeZd[i]^hbVcjVa#L]^X]ZkZg

ldg`"]daY^c\YZk^XZndjjhZ!bV`ZhjgZi]Vii]Z

ldg`e^ZXZ ^h]ZaY [^gbanVcYXZciZgZY id ZchjgZ

hV[ZVcYVXXjgViZdeZgVi^dc#