<.'). &'m(,7Zai9g^kZ<Ve7ZYAVi]Z

"(,"

Setting Feed Rate

;ZZYgViZ^hYZiZgb^cZYWni]ZbVX]^cZYbViZg^Va!

i]ZineZd[idda^c\jhZY!VcYWni]ZYZh^gZY[^c^h]#

GZ[Zg i]ZiVWaZ ^cFigure 52 dg i]ZMachinery's

Handbook[dg\j^YZa^cZh#

Note: These instructions are valid only for feed

rod power feed. Feed rate configuration for thread-

ing is discussed in the Threading subsection

starting on Page 40.

Recommended Feed Rates

Ldg`BViZg^Va

BV\cZh^jb

6ajb^cjb

7gVhh7gdcoZ

8deeZg

8Vhi>gdcHd[i

8Vhi>gdc=VgY

B^aYHiZZa

8VhiHiZZa

IddaHiZZa

6aadnHiZZah=VgY

HiV^caZhhHiZZa

I^iVc^jb

=^BV\VcZhZHiZZa

Idda;ZZYGViZ>EG

Rough Cuts Finish Cuts

%#%&*¶%#%'*

%#%&*¶%#%'*

%#%&*¶%#%'*

%#%&%¶%#%'%

%#%&*¶%#%'*

%#%&%¶%#%'%

%#%&%¶%#%'%

%#%&%¶%#%'%

%#%&%¶%#%'%

%#%&%¶%#%'%

%#%&%¶%#%'%

%#%&%¶%#%'%

%#%&%¶%#%'%

%#%%*¶%#%&%

%#%%*¶%#%&%

%#%%(¶%#%&%

%#%%)¶%#%%-

%#%%*¶%#%&%

%#%%(¶%#%&%

%#%%(¶%#%&%

%#%%(¶%#%&%

%#%%(¶%#%&%

%#%%(¶%#%&%

%#%%(¶%#%&%

%#%%(¶%#%&%

%#%%(¶%#%&%

Note: These values are a guideline only. Refer

to the MACHINERY’S HANDBOOK for more

detailed information.

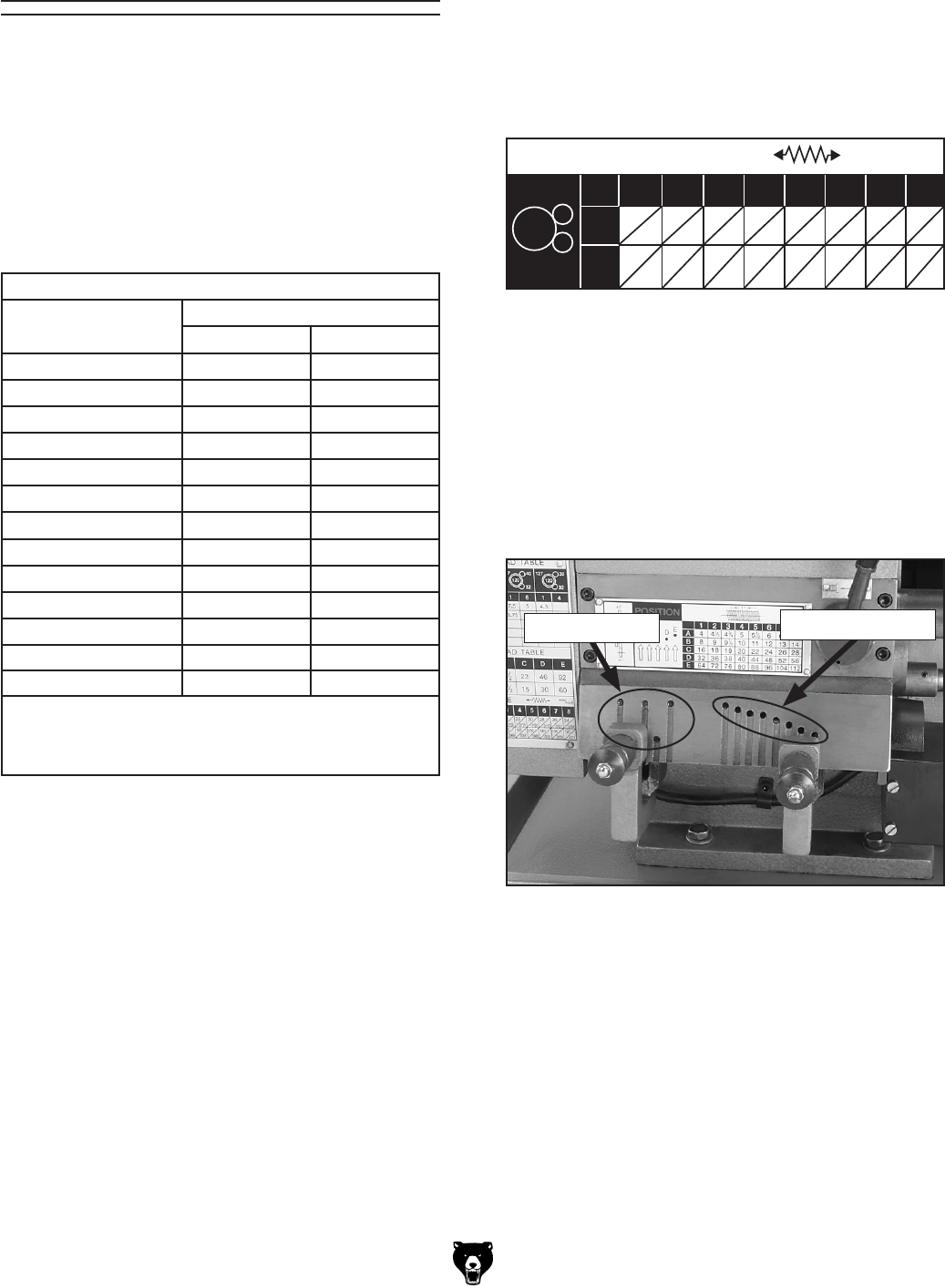

Figure 52.;ZZYgViZiVWaZ#

To set the feed rate:

1. JhZ i]Z he^cYaZ Y^gZXi^dc aZkZg id ijgc i]Z

he^cYaZOFF!i]ZcVaadli]Zhe^cYaZidXdb"

eaZiZanhideWZ[dgZbV`^c\\ZVgX]Vc\Zh#

2. BV`ZhjgZi]ZX]Vc\Z\ZVghVgZ^ci]ZXdc"

[^\jgVi^dc )%I$&',I$)%I! Vh ^aajhigViZY ^c

Figure 53gZ[ZgidChange Gears dcPage

38[dgYZiV^aZY^chigjXi^dch#

Note: The Model G9249 ships with the

change gears in the 40T/127T/40T configu-

ration, which will cover most feed rates and

inch threading.

Figure 54.;ZZYgViZhZaZXidgh#

AZiiZg>cYZcih

CjbWZg>cYZcih

3. GZ[Zgidi]ZiVWaZ^cFigure 53 VcY[^cYi]Z

kVajZXadhZhiidndjgYZh^gZY[ZZYgViZZ^i]Zg

^cb^aa^bZiZgheZggZkdaji^dcidekVajZhdg^c

^cX]ZheZggZkdaji^dcWdiidbkVajZh#

Note: This table is also on the bottom of the

label to the left of the feed rate selectors.

4. Ejaa i]Z `cdW d[ i]Z [ZZY gViZ hZaZXidg VcY

gdiViZ^iYdlc#A^cZjei]ZhZaZXidgl^i]i]Z

YZh^gZY ^cYZci! gdiViZ i]Z hZaZXidg je! VcY

Vaadli]Ze^cidZc\V\Z^cidi]Z^cYZcihZZ

Figure 54#

Note: It may be necessary to jog the spindle

to facilitate movement of the selectors.

FEEDING TABLE

mm

/inch

127

40

40

D

E

12345678

.42 .37 .35 .33 .30 .28 .26 .24

.0165 .0146 .0138 .0131 .0120 .0110 .0101 .0094

.210 .185 .175 .165 .150 .140 .130 .120

.0082 .0073 .0069 .0065 .0060 .0055 .0050 .0047

Figure 53.;ZZYgViZiVWaZ#

For Example: The operation is a shallow

finish cut on an aluminum workpiece. The

chart in Figure 52 recommends a feed rate

of 0.005–0.100 IPR (inches per revolution).

Because this is a shallow cut, we could select

a feed rate of 0.0082 IPR. To set this feed

rate, seat the left feed rate selector in the

"E" indent, and the right selector in the "1"

indent.