-20-

G9743 7" x 12" Metal-Cutting Bandsaw

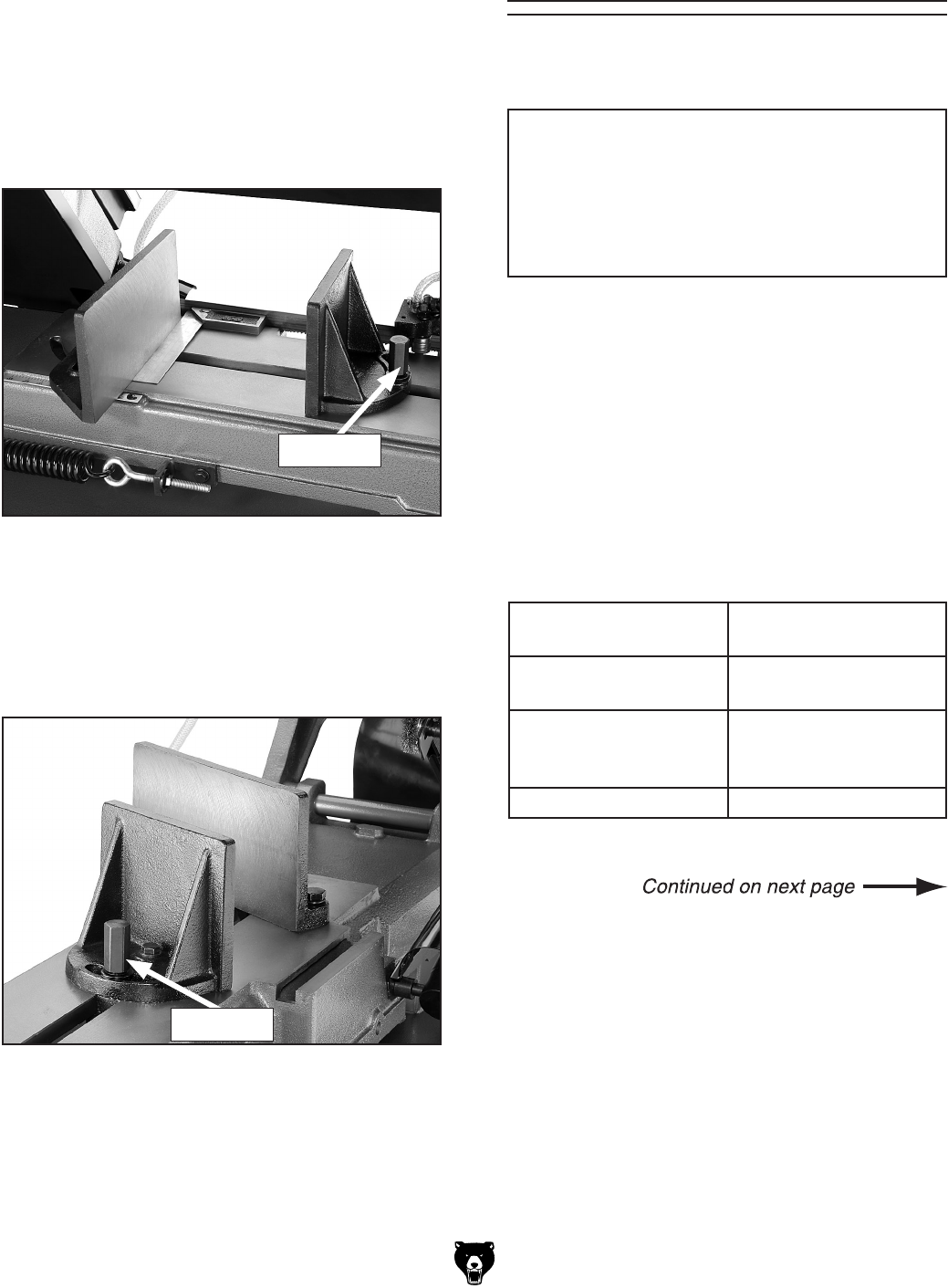

Figure 14. Vise jaw lock-nut.

4. Loosen the lock nut in Figure 14 on the

opposite jaw so the jaw can float, and match

the angle of the workpiece.

5. Tighten the vise against the workpiece.

Figure 13. Squaring vise to blade.

To adjust the angle on the vise:

1. Loosen the lock nut with a

3

⁄4" hex wrench.

2. Use the scale as a guide to set your angle or

use a machinist square to square the vise to

the blade as shown in

Figure 13.

3. Tighten the lock nut.

Blade Speed

To change blade speeds:

1. TURN THE BANDSAW OFF AND ALLOW IT

TO COME TO A COMPLETE STOP

.

2. Determine the best speed for your cut. The

ta

ble in Figure 15 is provided as a rough

guideline. Material thickness, type of blade

used and if cutting fluid is used, will factor

into the correct speed selection. As a general

rule, add 15% when using cutting fluid.

Material Feet Per Minute

(FPM)

Tool, Stainless, &

Alloy Steels, Cast Iron

148

Medium to High

Carbon Steels, Iron,

Hard Brass or Bronze

216

Aluminum and Plastics

282

Figure 15. Blade speed table.

NOTICE

DO NOT change speeds when the motor is

running. Wait for the bandsaw to come to a

complete stop or you will damage the gears

and you will void your warranty.

The Model G9743 has these three blade speeds:

148, 216, and 282 FPM.

Lock Nut

Lock Nut