H7678 18 Gauge Deep Stapler Kit

-15-

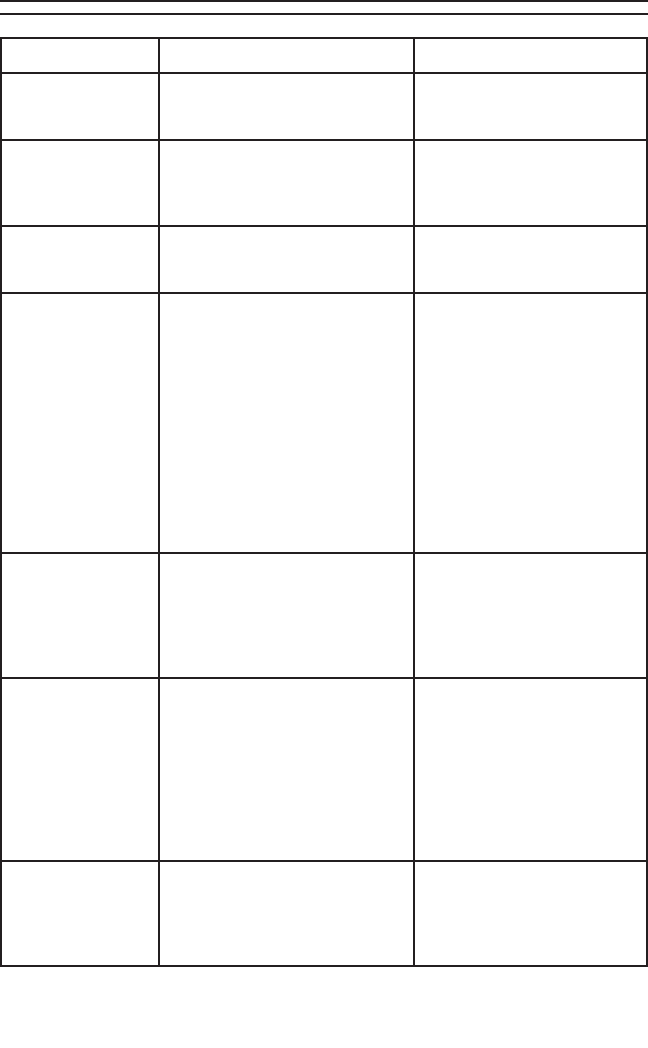

TROUBLESHOOTING

Symptom Possible Cause Solution

Air leaking at trig-

ger valve area.

1. O-rings in trigger valve hous-

ing are damaged.

1. O-rings must be replaced

& operation of safety yoke

must be checked.

Air leaking between

housing and hose.

1. Loose screws in housing.

2. Damaged O-ring.

3. Loose air fitting.

1. Tighten screws.

2. Replace O-ring.

3. Tighten air fitting & use tef

-

lon tape.

Air leaking between

housing and cap

assembly.

1. Damaged seal. 1. Replace damaged seals.

Tool skips staples

while discharging.

1. Air leaks.

2. Dirt in nose.

3. Dirt or damage prevents

staples from moving freely in

magazine.

4. Inadequate air flow to tool.

5. Worn O-ring on piston or lack

of lubrication.

6. Damaged O-rings on trigger

valve.

7. Worn bumper.

8. Cap seal leaking.

1. Tighten screws and fittings.

2. Clean nose.

3. Clean magazine and

inspect/repair damage.

4. Check fitting, hose, com

-

pressor & air pressure.

5. Replace piston O-ring.

Lubricate.

6. Replace trigger valve O-

rings.

7. Replace bumper.

8. Replace cap seal.

Tool runs slowly

or has a loss of

power.

1. Stapler is not sufficiently lubri

-

cated.

2. Broken spring in cap assem-

bly.

3. Exhaust port in cap is blocked.

1. Lubricate stapler.

2. Replace spring.

3. Clean or replace damaged

internal parts.

Fasteners frequent

-

ly jam the stapler.

1. Stapler is not sufficiently lubri-

cated.

2. Staples are the wrong size.

3. Staples are bent or dirty.

4. Magazine or nose screws are

loose.

5. Driver or driver guide are worn

or damaged.

1. Lubricate stapler.

2. Use correct staples.

3. Use undamaged, clean

staples.

4. Tighten magazine.

5. Replace worn or damaged

parts.

Stapler does not

fire.

1. Staple is jammed in magazine

or discharge area.

2. Piston shaft is damaged.

3. Air pressure too low.

1. Clear stapler magazine or

discharge area.

2. Replace piston shaft.

3. Check/increase air pres

-

sure.