SKU 04019 PAGE 9

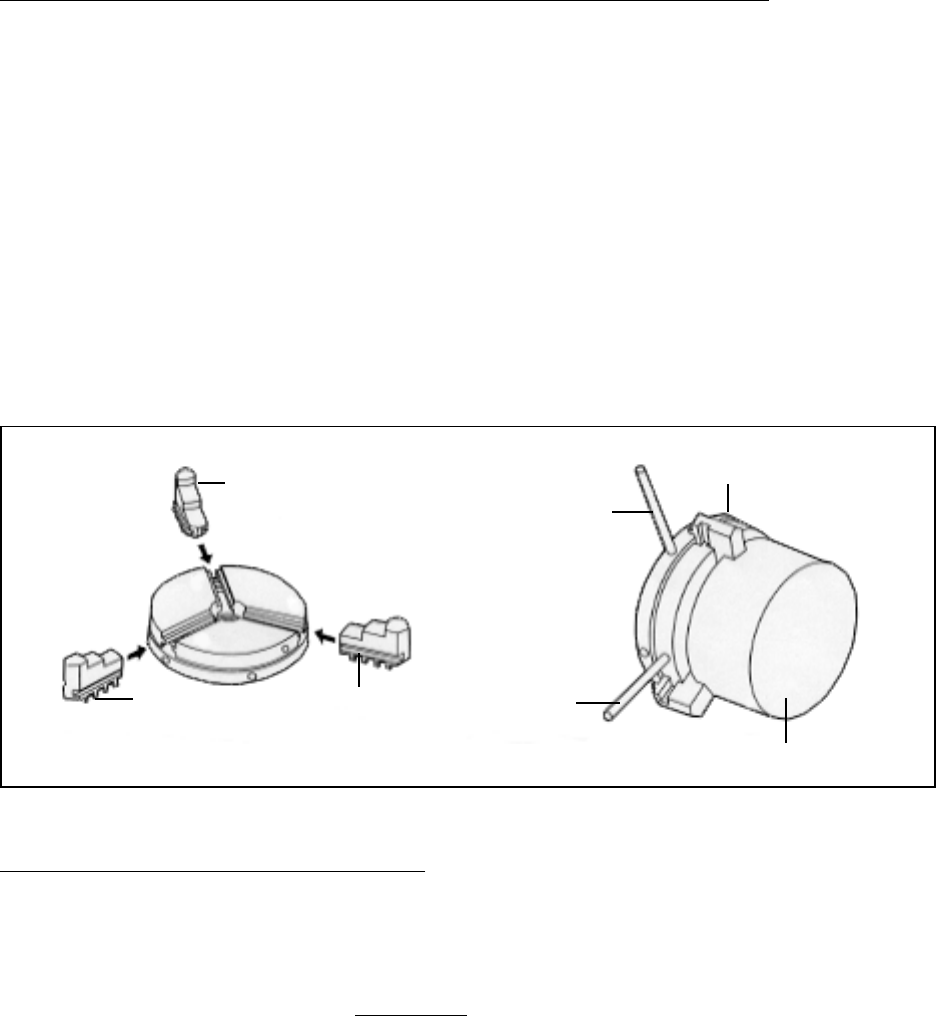

To Assemble The 3-Jaw Chuck For A Workpiece Up To 2” Diameter:

1. Workpieces with a diameter of up to 2” should be gripped with the external jaws

of the 3-Jaw Chuck (part #67). (See Figure E.)

2. If necessary, reverse the jaws for external gripping. To do so, unscrew, remove,

and clean each of the three jaws. Turn the knurled tension ring until the begin-

ning of the spiral thread comes to the respective groove. (See Figure D.)

3. The jaws are then inserted in the following order: (See Figure D.)

A. Jaw #1 is inserted in reverse in groove #3, then rotate the tension ring.

B. Jaw #2 is inserted in reverse in groove #2, then rotate the tenson ring.

C. Jaw #3 is inserted in in reverse in groove #1, then rotate the tension ring.

1

3

2

2

31

JAW

JAW

JAW

3-JAW CHUCK

(#67)

PIN

PIN

WORKPIECE

CAPACITY

UP TO

2”

FIGURE E

To Adjust The Tool Bit Center Height:

1. The tip of the tool bit (not included) must coincide exactly with the center of the

Tailstock Center (part #50). If the tip of the tool bit is not positioned properly, the

correct cutting dimensions cannot be obtained. Also, the tip of the tool bit may be

damaged. (See Figure F, next page.)

2. Place the tool bit in the Lathe’s Tool Holder (part #24), but do not yet tighten the

two Socket Screws (part #26) which clamp the tool bit in place. (See Figure F.)

3. Have several small, thin, metal, shims (not included) on hand. (See Figure F.)

4. Adjust the tip of the tool bit to the center of the Tailstock Center (part #50). If

necessary, insert the shim(s) under the tool bit in order to obtain the proper

centering. (See Figure F.)