Page 13SKU 65345 For technical questions, please call 1-800-444-3353.

Replace the Back Lid (20) and Side 7.

Lid (63). (See Figures E and F.)

FIGURE I

Recommended Turning Speeds

Work Diameter

In Inches

Speeds (RPM)

0~2” 2200~3200

2”~3” 1600~2200

3”~4” 1100~1600

4”~5” 750~1100

6”+ 750

Note: The above speeds can vary with different

types of wood and the skill of the operator.

Sanding: Use the fastest speed possible with-

out burning the wood.

Polishing and Finishing: Typically, polishing

and nishing can be done at faster speeds than

turning.

To Adjust The Tailstock:

Loosen the Release Lever (7) and 1.

move the Tailstock (5) to the desired

position. Then retighten the Release

Lever. NOTE: If the Release Lever

will not release or lock the Tailstock

(either too tight or too loose), tighten

or loosen the Hex Nut (44) located on

the underside of the Tailstock in small

increments as needed to achieve the

proper clamping pressure.

(See Figure J and Assy. Diagram.)

FIGURE J

RELEASE

LEVER

(7)

TAILSTOCK

(5)

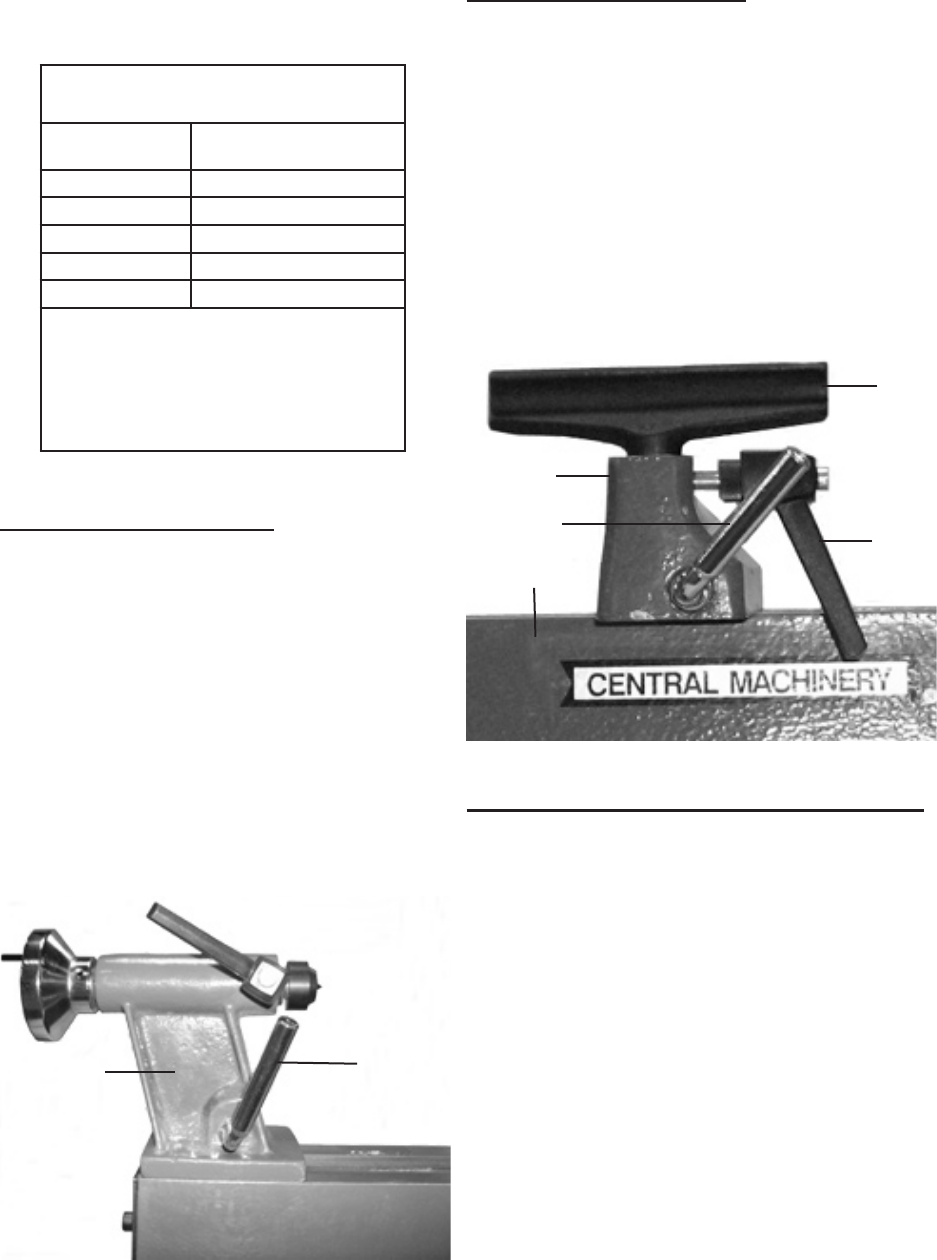

To Adjust The Tool Rest:

Loosen the Lock Handle (40) and slide 1.

the Tool Rest Base (36) along the

Bed (1) to the desired position. Then

retighten the Lock Handle.

(See Figure K.)

Loosen the Lock Lever (41) and adjust 2.

the Tool Rest (35) vertically or swivel

it as needed. Then retighten the Lock

Lever. (See Figure K.)

FIGURE K

LOCK

HANDLE

(40)

LOCK

LEVER

(41)

TOOL

REST

(35)

BED

(1)

TOOL

REST

BASE

(36)

To Install And Remove The Spur Center:

To install1. , insert the tapered end of

the Headstock Spur Center (12) into

the Headstock Spindle (14). Make

sure the Headstock Spur Center is se-

curely installed by giving it a quick pull.

A properly installed Headstock Spur

Center will not pull out by hand.

(See Figure L, next page.)

To remove2. , hold the Balance Wheel

(22) securely while turning the Face-

plate (13) counterclockwise until the

Headstock Spur Center (12) is forced

out of the Headstock Spindle (14).

(See Figure L, next page.)