Page 11For technical questions, please call 1-800-444-3353.SKU 67696

68149

must be replaced only by a qualied

service technician.

Maintenance Schedule

Following are general guidelines

for maintenance checks of the Air

Compressor.

Note: The environment in which the

compressor is used, and the frequency

of use can affect how often you will need

to check the Air Compressor components

and perform maintenance procedures.

Daily:

Make sure all nuts and bolts are tight.a.

Drain moisture from air tank.b.

Check for abnormal noise or vibration.c.

Check for air leaks.d.

1

Wipe off any oil or dirt from the e.

compressor.

2

Monthly:

Inspect Safety Valve.a.

1 To check for air leaks, apply soapy water

to joints while the Air Compressor is

pressurized. Look for air bubbles.

2 To clean the compressor surface, wipe

with a damp cloth, using a mild detergent

or mild solvent.

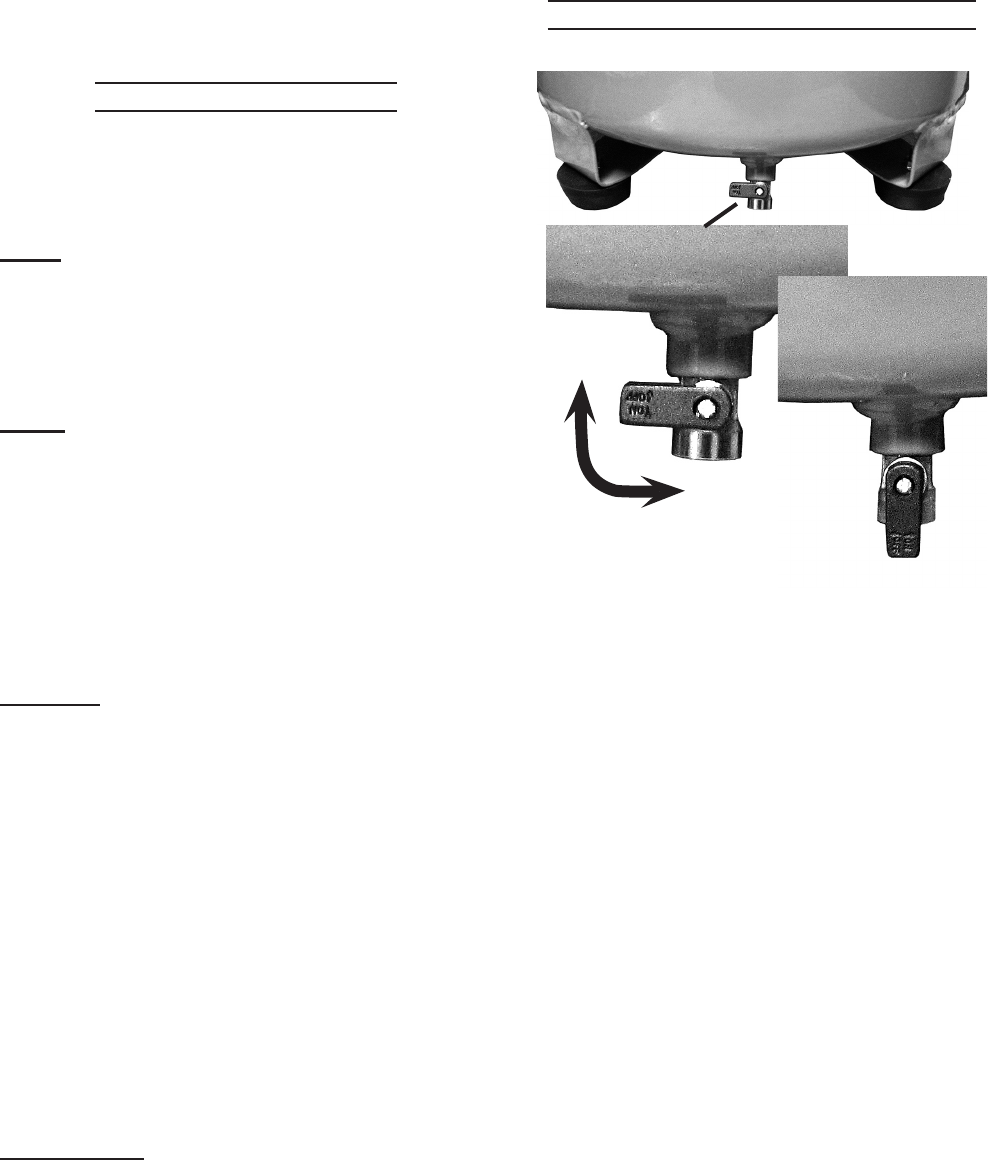

Draining Moisture from the Tank

Figure 6

Drain Valve (107)

Closed

Open

Back of Compressor

The Drain Valve is located under the

Tank. It must be accessed daily to

release all trapped air and moisture

from the Tank. This will eliminate

condensation which can cause internal

tank corrosion.

To empty the air and condensation:

Switch the compressor off.1.

Place a collection pan under the Drain 2.

Valve.

Open the Drain Valve.3.

Holding the compressor Handle (515), tilt 4.

the compressor toward the Drain Valve

and drain all moisture into the collection

pan.

When all the pressure and moisture is 5.

released, close the Drain Valve.