Page 13SKU 97503 For technical questions, please call 1-800-444-3353.

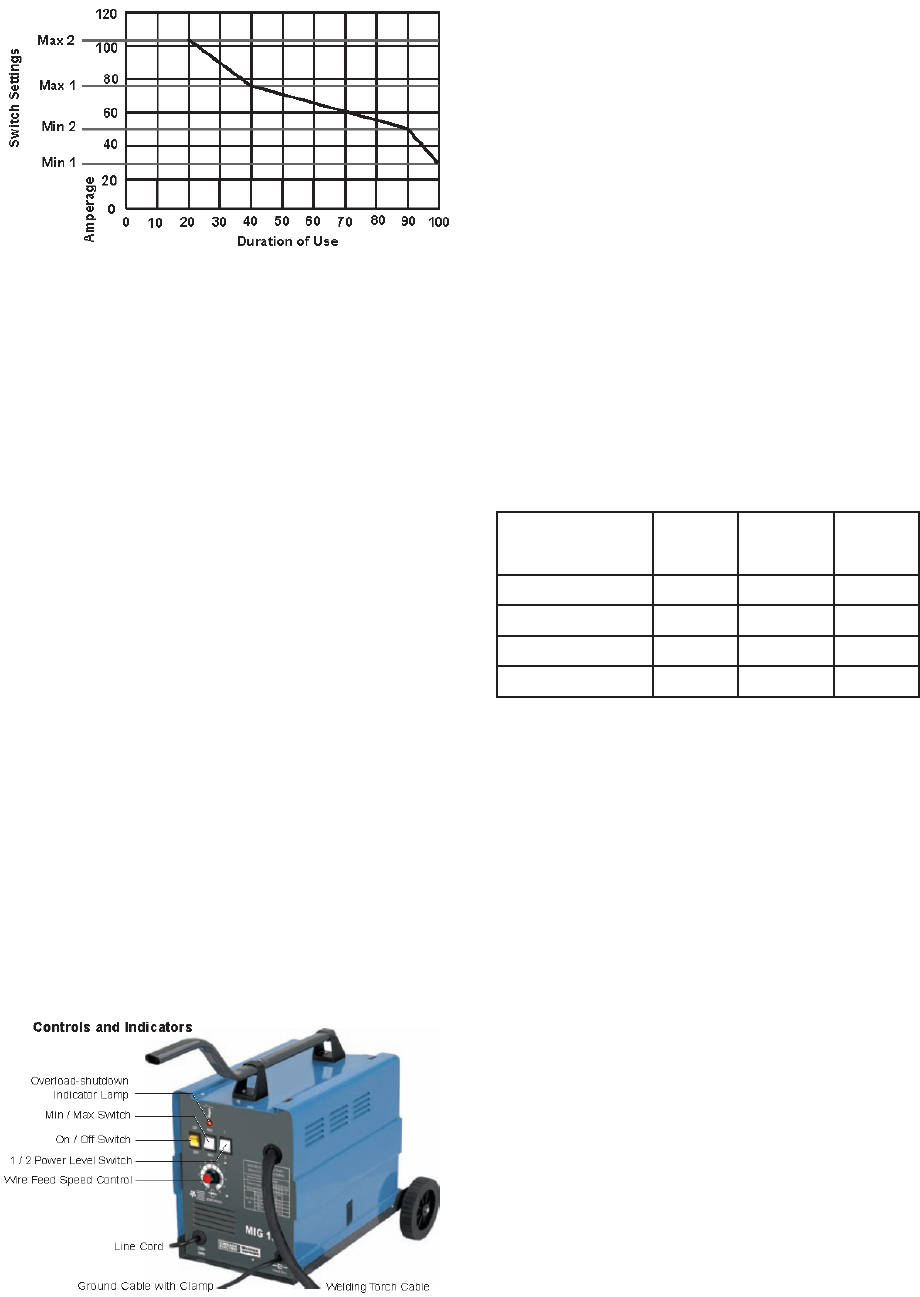

The duty cycle denes the number of

minutes, within a 10 minute period, during

which a given Welder can safely produce

a particular welding current. For example,

this Welder, with a 20% duty cycle at 105

Amps (setting Max 2), must be allowed

to rest for at least 8 minutes after two

minutes of continuous weld at 105 Amps.

Failure to carefully observe duty •

cycle limitations can stress a

Welder’s power generation system,

contributing to premature Welder

failure.

This Welder is equipped with an •

internal thermal protection system

to help prevent damage to the

unit. When the unit overheats; it

automatically shuts down, then

returns to service when it cools

down.

Once the unit returns to service, •

follow a more conservative duty

cycle routine to help prevent excess

wear to the Welder.

Always read and follow wire 1.

manufacturer’s recommended

polarity. If using non-ux core wire,

secure the Argon/CO2 gas hose to

the rear of the MIG Welder. (If using

ux core wire, protective gas is not

required.)

Attach the Ground Cable with Clamp 2.

(14) as close as possible to the metal

object to be welded.

Set the desired current (30~120 3.

amps) for the type of metal being

welded with the Temperature

Controller. Thin metals use low

current and heavy metals use high

current.

Set Switch Amps Duty

Cycle

Volts

Min. / 1 30 100% 15.2

Min. / 2 50 90% 16.5

Max. / 1 75 40% 17.7

Max. / 2 105 20% 19.2

Make sure the power switch is off, 4.

then plug the MIG Welder Power

Cord into a dedicated, 230 VAC, 20

amp line with delayed action type

circuit breaker or fuses.

While holding the Welding Torch 5.

handle, with the electrode wire clear

of grounded objects, turn the Power

Switch ON.

Momentarily press the Welding Torch 6.

trigger switch to test the wire feed

speed. Adjust the speed by turning

the Wire Speed Knob.

Hold the Arc Shaded Face Shield 7.

over your eyes.

Press (and hold) the Torch Trigger 8.

Switch and stroke the area to be