SKU 98751 For technical questions, please call 1-800-444-3353. Page 14

force. Keep your ngers clear when

releasing.

5. If you are unable to clear the nail

jam using the method prescribed

above, the tool should be taken to

a qualied service technician for

proper servicing.

User-Maintenance Instructions

Procedures not specically

explained in this manual

must be performed only by a

qualied technician.

TO PREVENT

SERIOUS INJURY

FROM ACCIDENTAL

OPERATION:

Turn off the tool, detach the

air supply, safely discharge

any residual air pressure in

the tool before performing any

inspection, maintenance, or

cleaning procedures.

TO PREVENT SERIOUS

INJURY FROM TOOL

FAILURE:

Do not use damaged

equipment. If abnormal

noise, vibration, or leaking

air occurs, have the problem

corrected before further use.

TO PREVENT EXPLOSION:

Lubricate the tool only

with specied lubricants.

Lubricate the air inlet

using only pneumatic tool

oil. Lubricate the internal

mechanism using only

white lithium grease. Other

lubricants may damage the

mechanism and may be

highly ammable, causing an

explosion.

WARNING! Anytime any

maintenance or repairs are

done, wear ANSI-approved

impact safety goggles and

appropriate hearing protection.

THEN:

a. Disconnect the Nailer from its air

supply.

b. Empty the Magazine (79) com-

pletely.

c. Try to re the Nailer into a piece of

scrap wood to ensure that there is

no trapped air in the system.

d. Always leave Magazine open dur-

ing maintenance. The Magazine

is spring-loaded and may cause

parts or a nail to y out of Nailer.

6. Dirt in the air supply is a major cause

of pneumatic tool wear. Use a lter in

the compressed air system for better

performance and longer tool life.

7. Make sure Trigger (59) and Safety

Nosepiece (42) move freely, with-

out sticking. Do not use nailer if

Trigger or Safety Nosepiece sticks.

8. Wipe down exterior of the Nailer with

a clean cloth before storing.

9. Store in a clean, dry and safe location

out of reach of children.

REV 09e

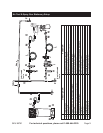

User-Maintenance