10

English

The laser line is adjusted to the width of the saw blade at the time of

factory shipment. Adjust the positions of the saw blade and the laser

line taking the following steps to suit the use of your choice.

Fig. 14

(1) Light up the laser marker and make a groove of about 3/16 in. (5mm)

deep on the workpiece that is about 1-1/2 in. (38mm) in height and

3-1/2 in. (89mm) in width. Hold the grooved workpiece by vise as it

is and do not move it.

Fig. 15

(2) Then insert a 4mm hex. bar wrench in the 12 diameter hole on the

side of the gear case, turn the hex. socket set screw to move the

laser line. (If you turn the Hex. socket screw clockwise, the laser line

will shift to the right and if you turn it counterclockwise, the laser

line will shift to the left.) When you work with the ink line aligned

with the left side of the saw blade, align the laser line with the left

end of the groove. (Fig. 16) When you align it with the right side of

the saw blade, align the laser line with the right side of the groove.

Fig. 16

(3) After adjusting the position of the laser line, draw a right-angle ink

line on the workpiece and align the ink line with the laser line. When

aligning the ink line, slide the workpiece little by little and secure it

by vise at a position where the laser line overlaps with the ink line.

Work on the grooving again and check the position of the laser line.

If you wish to change the laser line’s position, make adjustments

again following the steps from (1) to (3).

Saw blade

Marking

(pre-marked)

Workpiece

Cutting width

Fig. 17

NOTE:

Check and make sure on a periodic basis if the position of the laser

line is in order. As regards the checking method, draw a right-angle

ink line on the workpiece with the height of about 1-1/2 in. (38mm)

and the width of 3-1/2 in. (89mm), and check that the laser line is in

line with the ink line [The deviation between the ink line and the

laser line should be less than the ink line width (0.5mm)]. (Fig. 17)

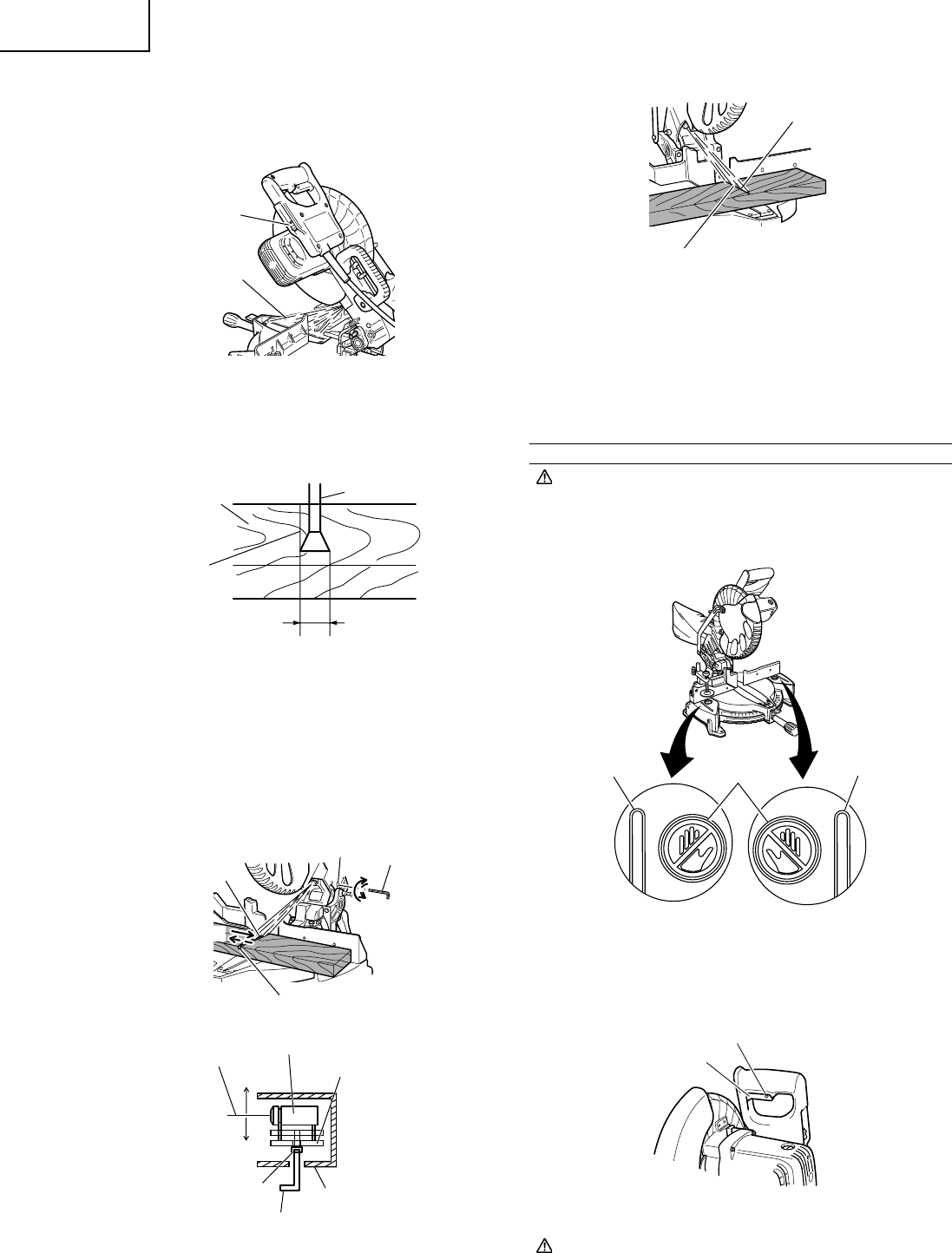

PRACTICAL APPLICATIONS

WARNING:

* To avoid personal injury, never remove or place a workpiece on

the table while the tool is being operated.

* Never place your limbs inside of the line next to warning sign

while the tool is being operated. This may cause hazardous

conditions (see Fig. 18).

Fig. 18

1. Switch operation

Pull the trigger to turn on the switch, release it to shut it off.

After releasing the trigger, make sure the trigger has gone all the

way back and the switch is turned off.

Fig. 19

WARNING:

This will ensure that the power tool cannot be turned on accidentally

or by someone (especially a child) who is not qualified to use the

power tool.

To prevent unauthorized operation of this tool, insert a padlock to

the hole in the switch trigger to disable the use of the switch.

2. Using the Vise Assembly (Standard accessory)

(1) The vise assembly can be mounted on either the left fence {Fence

(B)} or the right fence {Fence (A)} by loosening the 6mm wing bolt

(A).

Switch

Laser line

Laser marker

Laser line

Left

Right

Hex socket

bolt

Hex bar wrench

(Accessories)

Laser holder

Gear case

Laser line

Marking

(pre-marked)

Line

Warning

sign

Line

Trigger switch

Hole

Turn

Groove

Laser line

4mm Hex.

bar wrench

Move

ø12 Hole

01Eng_C10FCH2_US 6/15/07, 19:0910