— 11 —

English

TESTING THE NAILER

DANGER

ⅷ Operators and others in

work area MUST wear

safety glasses with side

shields which conforms

to ANSI Z87.1

specifications.

WARNING

ⅷ Never use Nailer unless push lever is operating

properly.

ⅷ Do not push tool forward when positioning the

first nail in metal hole. If pushing forward, nail

head will be damaged and broken, or will cause

jamming.

This tool has a Sequential Trip Mechanism (Single Shot)

for use when precision nail placement is necessary.

You must first depress the nail point where you

want to drive a nail and then pull the trigger.

After the nail is driven, completely release the

trigger and lift the tool off the work surface.

This tool is not designed for contact trip operation

(bounce fire), and not available for contact trip valve units.

And this tool has a new push lever (safety) mechanism,

this is a different push lever mechanism from another

nailers.

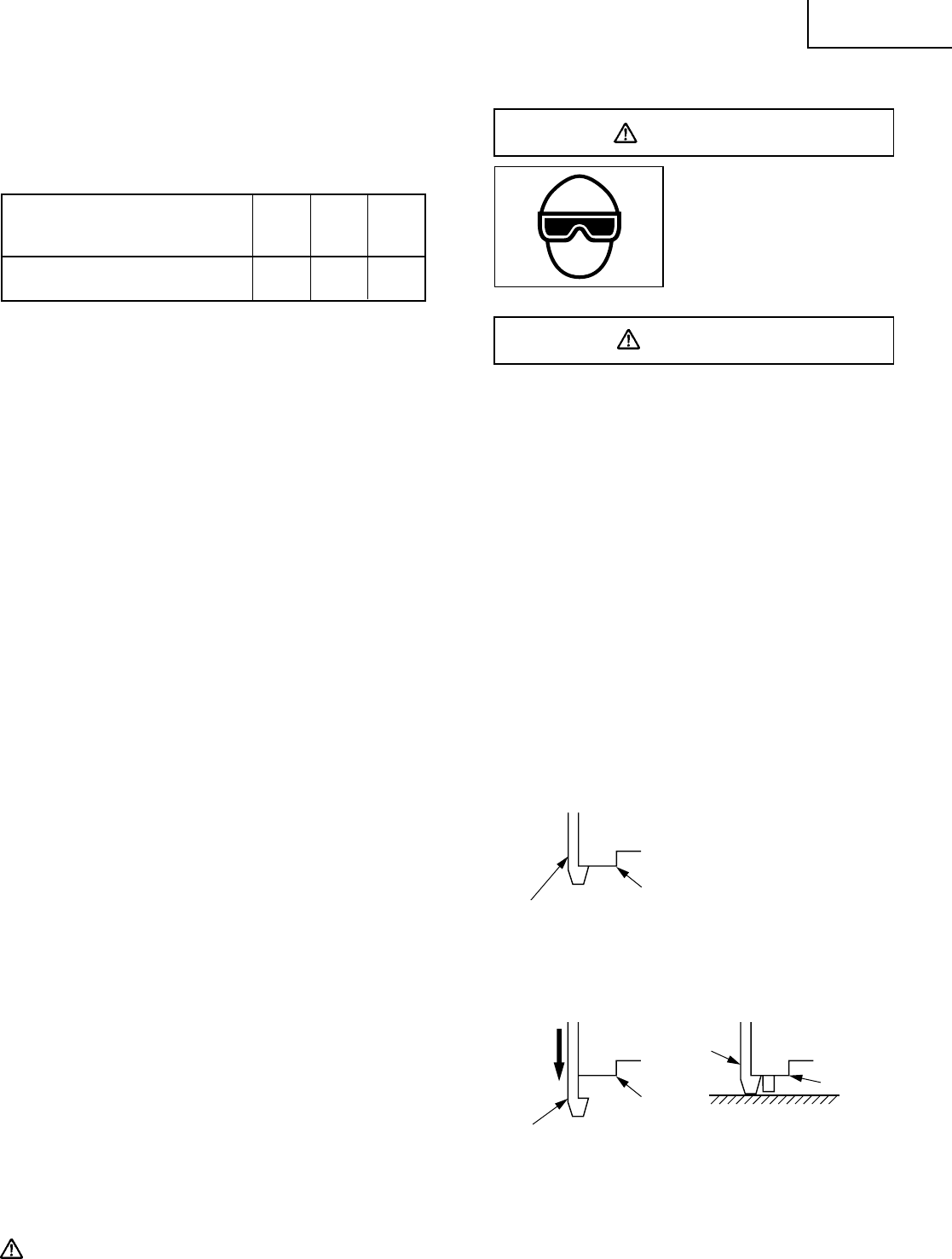

The position of the push lever when the nail feeder is

pulled back is shown as below.

When nails are loaded and the trigger is depressed, the

push lever comes down and when the push lever touches

the workpiece, a nails is driven.

This tool is equipped with a lockout feature that prevents

the tool from being activated when there are 5 or less

nails in the magazine.

5. Air consumption

Using the Air consumption table and the Air

compressor size formula, find a correct compressor

size.

Air consumption table

Air compressor size formula

Amount of air required

=number of Nailers

× average nails driven each minute per Nailer

× air consumption at given air pressure

× safety factor (always 1.2)

Example: 2 Nailers operating at 100 psi driving 30 nails

per minute

Amount of air required

=2 × 30 × .063 (1.8) × 1.2

=4.5 CFM (ft

3

/min) (180 ltr/min)

After making the calculations as shown above, you

should find a compressor providing 4.5 CFM of air that

is required.

LUBRICATION

It is important that the Nailer be properly lubricated.

Without proper lubrication, the Nailer will not work

properly and parts will wear prematurely.

⅜ Use Hitachi pneumatic tool lubricant.

Do not use detergent oil or additives. These lubricants

will harm the O-rings and other rubber parts. This will

cause the Nailer to malfunction.

⅜ Filter-regulator-lubricator units should always be

used.

Keep the lubricator filled with Hitachi pneumatic tool

lubricant.

⅜ If a lubricator is not available, supply 5 – 10 drops of

Hitachi pneumatic tool lubricant into the air plug on

the Nailer twice a day.

COLD WEATHER CARE

⅜ Do not store the Nailer in a cold weather environment.

Keep the Nailer in a warm area until beginning the

work.

⅜ If the Nailer is already cold, bring it in a warm area

and allow the Nailer to warm up before use.

1 Reduce the air pressure to 70 psi (4.9 bar

5 kgf/cm

2

).

2 Remove all nails from the Nailer.

3 Connect the air hose and free-fire (blank-fire) the

Nailer.

The lowered air pressure will be enough to free-

fire the Nailer.

Slow speed operation tends to warm up the

moving part.

CAUTION

ⅷ Do not free-fire the Nailer at high pressure.

psi 80 90 100

Operating pressure (bar) (5.5) (6.2) (6.9)

(kgf/cm

2

) (5.6) (6.3) (7)

Air consumption

ft

3

/cycle .05 .056 .063

(ltr/cycle) (1.4) (1.6) (1.8)

Push Lever

At Non-Firing

Nose

Push Lever

At Firing

Nose

Push Lever

Nose

Workpiece