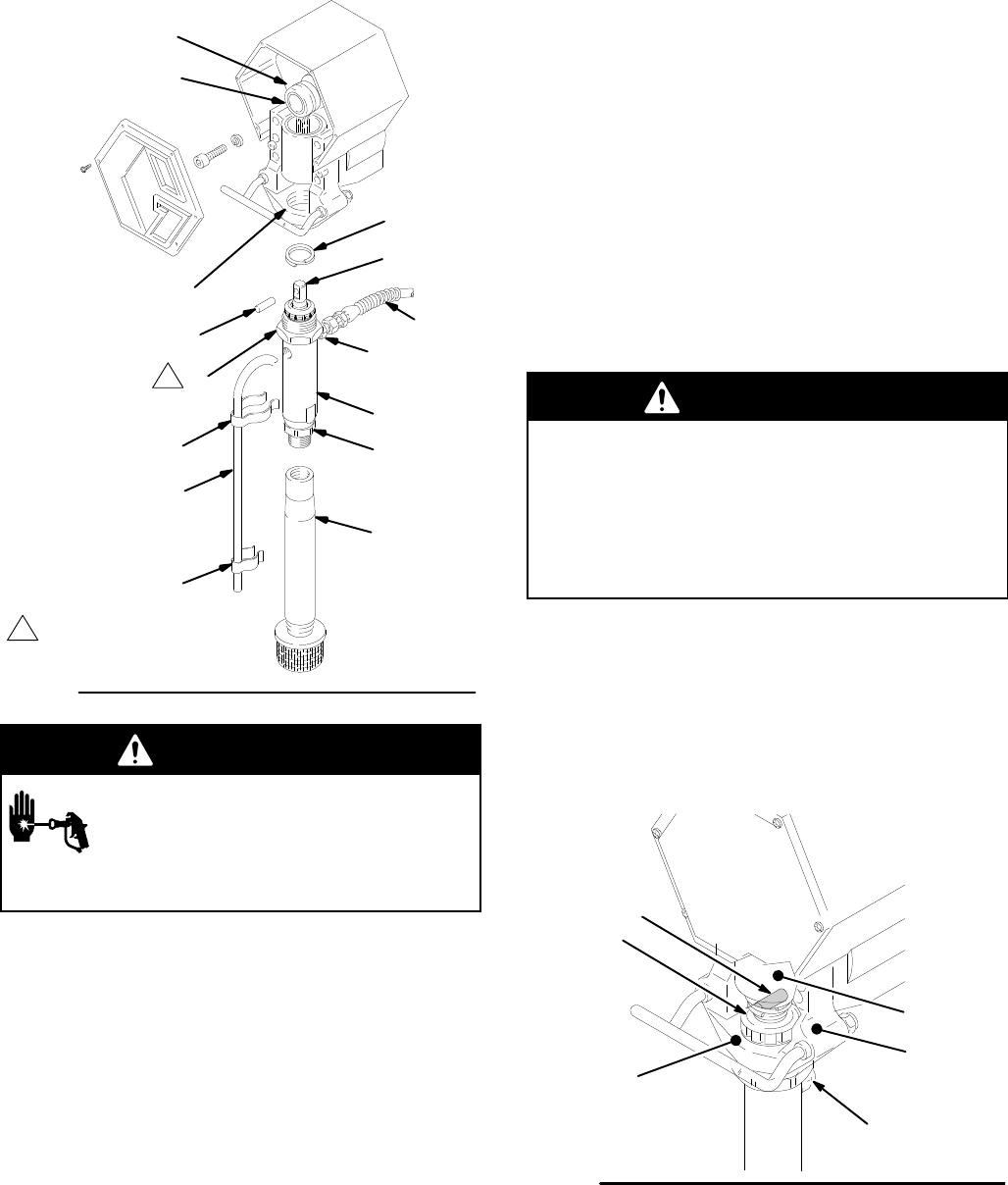

14 307-830

Displacement

Pump

01746B

Fig.

14

222

30

4

49

223

6

50

51

A

Torque

to

80 ft–lb (107 N.m)

3

52

32

76

75

74

1

1

WARNING

INJECTION

HAZARD

T

o reduce the risk of serious bodily

injury

, follow the

Pressure Relief Proce

-

dure W

arning

on page 1

1 before check

-

ing or repairing any part of the spray system.

Removing the pump See

Fig. 14.

1.

Flush the sprayer

. Relieve pressure.

2.

Remove the clips (74,76) and drain hose (75).

3.

Hold the intake valve (222) steady with a wrench

and unscrew the suction tube (3).

4.

Use a screwdriver to push the retaining spring (49)

up, and then push out the pin (50).

5.

Loosen the locknut (6). Unscrew the pump (4).

Repairing the pump

See

manual 307–806 for pump repair instructions.

Reinstalling the pump See

Fig. 14 and 15.

1.

Rotate the crankshaft (A) so the connecting rod is

in its lowest position.

2.

The pump piston rod (223) should protrude about

1 in. (25 mm) above the pump cylinder

.

3.

Screw the pump into the bearing housing (51) until

its pin hole is aligned with the connecting rod (52)

pin hole. Insert the pin (50). Position the spring

(49) so it covers the ends of the pin. See Fig. 15.

WARNING

Be sure the retaining spring (49) is firmly and com-

pletely

in the groove of the connecting rod to

prevent

the

pin (50) from working loose due to vibration.

If

the pin works loose, it or other parts could break of

f

due to the force of the pumping action, resulting in

serious

bodily injury

, pump or property damage.

4.

Adjust the pump so the cylinder

’

s top threads are

flush with the face (B) of the bearing housing and

the outlet nipple (32) is straight back. See Fig. 15.

5. T

orque the locknut (6) to 80 ft-lb (107 N.m).

6.

Reassemble the remaining parts, in the reverse

order of removal.

01751A

Fig. 15

51

52

50

49

B

32