307-830 15

Connecting

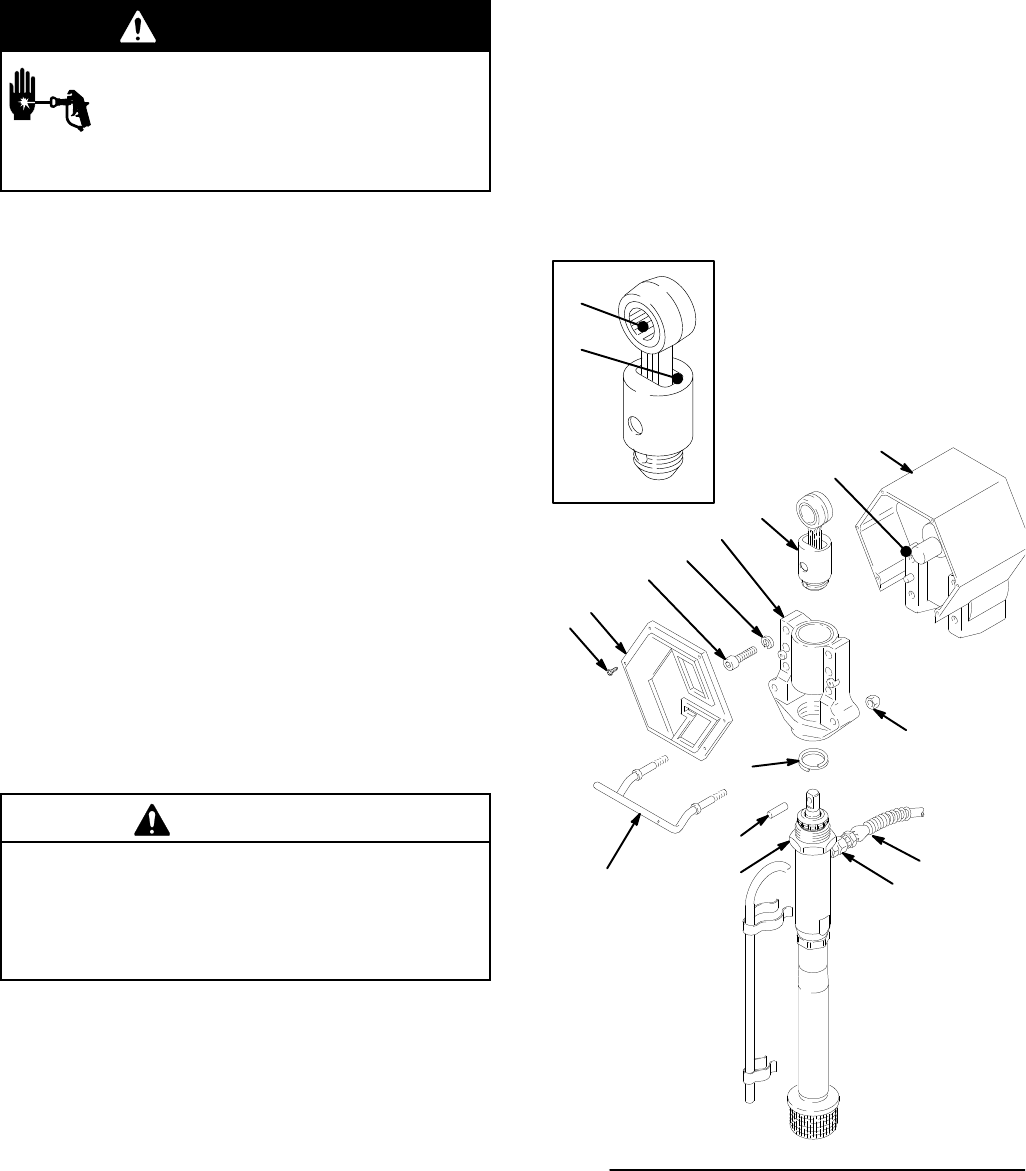

Rod and Bearing Housing

WARNING

INJECTION

HAZARD

T

o reduce the risk of serious bodily

injury

, follow the

Pressure Relief Proce

-

dure W

arning

on page 1

1 before check

-

ing or repairing any part of the spray system.

NOTE:

Refer to Fig. 16.

1.

Remove the pail hanger (7).

2.

Remove the front cover (12).

3.

Remove the pump as described on page 14.

4.

Remove the four screws (9) and lockwashers (10).

Pull the bearing housing (51) and connecting rod

assembly (52) of

f the crankshaft (C).

5.

Clean and inspect the crankshaft (C). Wipe it clean

with a rag (don’t use solvent). If the crankshaft is

badly worn, replace the drive assembly (14). See

page 21.

6.

Clean and inspect the bearing housing (51) and

connecting rod (52), including the needle bearing

(A). Replace both parts if either is worn or dam

-

aged. See Detail A.

7.

Clean the mating surfaces of the bearing and drive

housings.

CAUTION

T

o extend the service life of the connecting rod

bearing, lubricate it properly

. After every 100 hours of

operation, or whenever servicing the pump (whichev

-

er comes first), fill the cavity (B) in the connecting

rod with SAE non-detergent motor oil. See Detail A.

8.

Coat the surfaces of the connecting rod and bear

-

ing with SAE non-detergent motor oil. Liberally

pack the needle bearing (A) with industrial grade,

heavy duty

, extreme pressure, lithium soap

grease. See Detail A.

9.

Assemble the connecting rod (52) and bearing

housing (51).

10.

Align the connecting rod (52) with the crank (C)

and push the bearing housing (51) onto the drive

housing (14).

11.

Assemble the remaining parts. Refer to page 14 to

reinstall the pump.

01750B

Fig. 16

30

32

C

9

10

52

51

12

49

7

50

6

A

14

B

13

5

Detail A