OM-927 Page 22

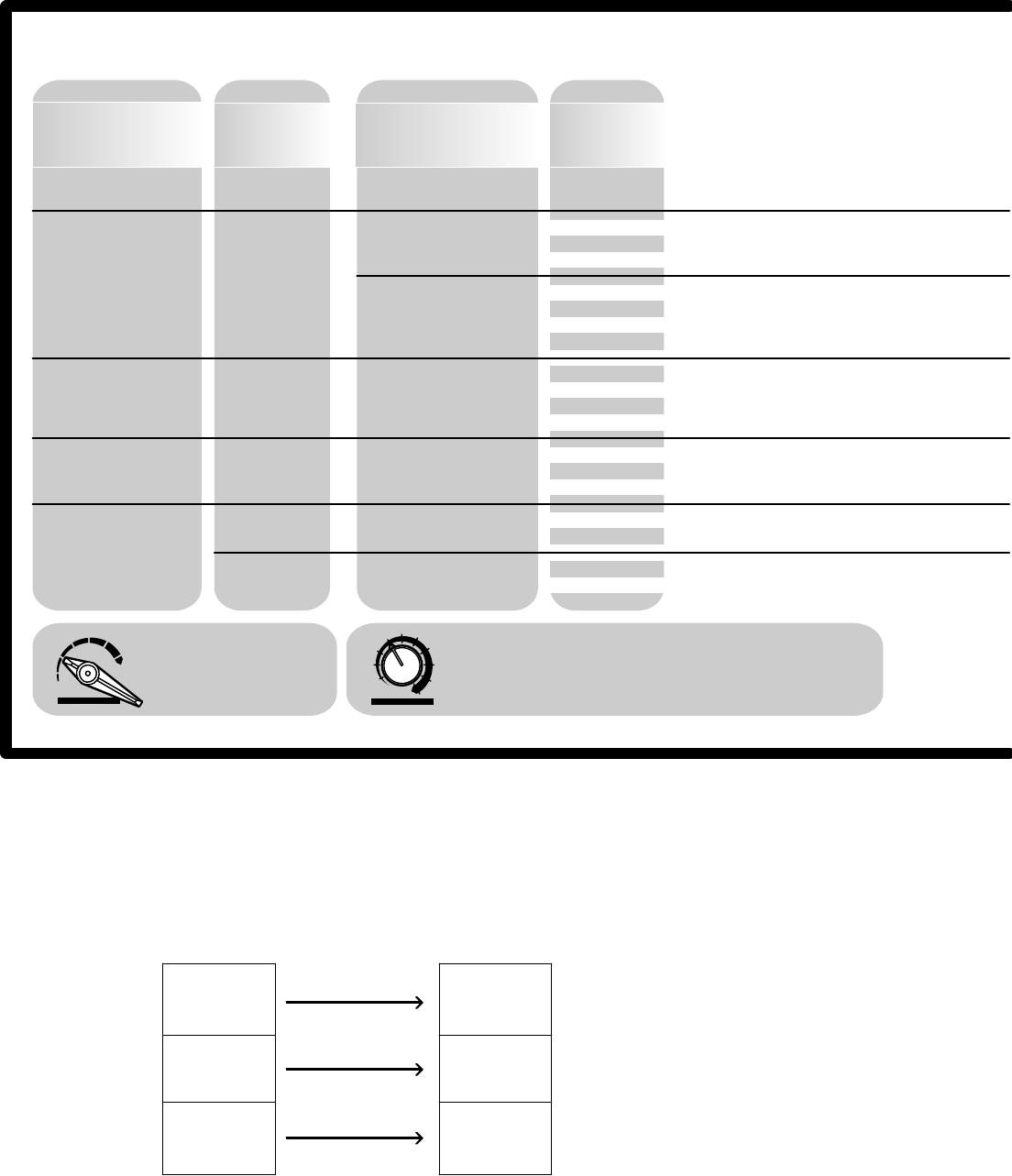

4-2. Weld Parameters

Input Line

Voltage

Parameter

Chart Settings

Higher

e.g. 240

Volts AC

230 Volts AC

Lower

e.g. 218

Volts AC

Weld Will Be

Hotter

Lower Settings

Use Parameter

Chart Inside

Door

Weld Will Be

Colder

Raise Settings

Steel

Steel– for outdoor,

windy applications or

when weld appearance

is not critical.

Stainless steel

Aluminum−with

Optional Hobart

3035−20

Spool Gun

Solid (or hard)

ER70S−6

Fluxcore

E71T−GS

Stainless steel

ER 308

Aluminum

4043 AL

Aluminum

5356 AL

No shielding gas

100% Ar, 20 cfh

100% Ar, 20 cfh

.023”(0.6 mm)

.030”(0.8 mm)

.035”(0.9 mm)

.023”(0.6 mm)

.030”(0.8 mm)

.035”(0.9 mm)

.030”(0.8 mm)

.035”(0.9 mm)

.045”(1.1 mm)

.023”(0.6 mm)

.030”(0.8 mm)

.035”(0.9 mm)

.030”(0.8 mm)

.035”(0.9 mm)

.030”(0.8 mm)

.035”(0.9 mm)

Selecting Wire, Gas and Control Settings

10

20

30

40

50

60

70

80

90

WIRE SPEED

VOLTAGE

1

2

3

4

5

6

CAUTION! Do not change

Voltage switch position

while welding.

What Material

Suggested

Wire Types

Suggested

Shielding Gases

and Flow Rate

Wire Sizes

(Diameter)are You Welding?

required

Tri-Mix 20 cfh

(90% He/7.5% Ar/

2.5% CO

2

)

75% Ar/25% CO

2

, 20

cfh (Ar/CO

2

, produces

less spatter − better

overall appearance

100% CO

2

, 20 cfh

Wire Speed listed is a starting value only − Wire Speed

setting can be fine−tuned while welding. Wire Speed

also depends on other variables, such as stick out, travel

speed, weld angle, cleaniness of metal, etc.