OM-927 Page 23

Ref. 199 208-B

3/8”

(9.5 mm)

—

5/58

5/52

5/100

5/72

5/60

5/66

5/44

5/30

—

—

—

—

—

—

—

1/4”

(6.4 mm)

—

4/48

4/34

5/100

4/62

4/52

4/52

4/36

5/30

6/90

6/76

6/70

6/78

6/72

6/100

6/84

1/8”

(3.2 mm)

3/46

3/34

3/20

4/80

3/42

3/40

2/20

2/10

3/10

5/82

5/64

5/66

4/68

4/60

4/88

4/84

14 ga.

(2.0 mm)

3/46

3/32

3/18

3/68

3/40

3/36

2/14

2/4

—

4/70

4/56

4/40

2/68

2/58

2/80

2/70

16 ga.

(1.6 mm)

2/18

2/14

2/12

2/36

2/24

2/20

1/12

1/0

—

3/50

3/46

3/32

1/56

—

1/70

—

18 ga.

(1.2 mm)

2/18

2/12

2/12

2/36

2/24

2/16

1/12

—

—

3/46

3/46

3/28

—

—

—

—

20 ga.

(0.9 mm)

2/18

2/10

—

1/16

1/16

2/14

—

—

—

3/42

3/40

2/24

—

—

—

—

22 ga.

(0.8 mm)

2/16

—

—

1/16

1/16

—

—

—

—

3/42

2/32

—

—

—

—

—

3/16”

(4.8 mm)

4/74

4/44

4/34

4/80

4/62

4/50

3/46

3/20

4/20

5/86

5/68

5/66

5/72

5/66

5/88

5/84

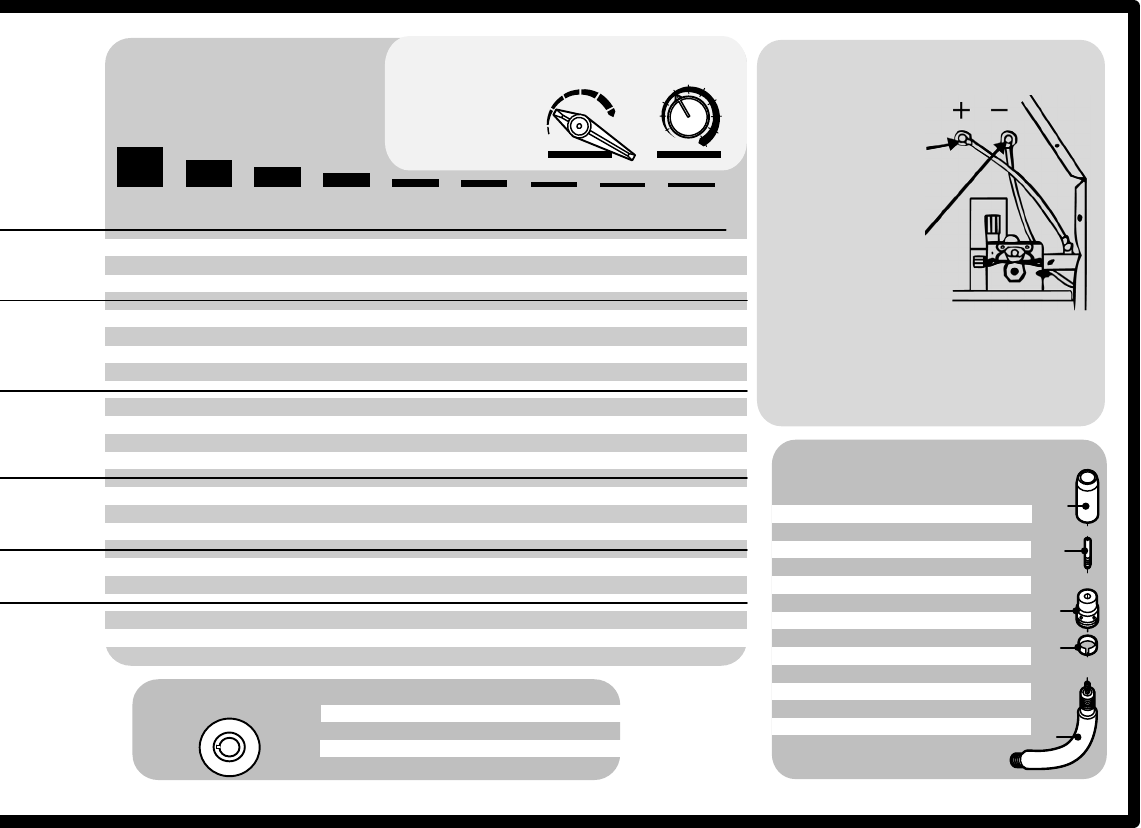

VOLTAGE

1

2

3

4

5

6

10

20

30

40

50

60

70

80

90

WIRE SPEED

Wire Size Stock No.

V−Grooved .024”,.030”/.035”

202925

.024”,.045”

407230−004

V−Knurled .030”/.035”

193330

.039”/.045”, .056”2”/ 1/16”

193331

A) Nozzle

.500 orf flush #169 715

B) Tips

.023/0.6 mm #087 299

.030/0.8 mm #000 067

.035/0.9 mm #000 068

.045/1.1 mm #000 069

C) Contact Tip Adapter #169 716

D) Retaining Ring #170 470

E) Head Tube #169 718

Liners

.023/.025 #194 010

.030/.035 #194 011

.035/.045 #194 012

M−10 Consumables

DriveRolls

A

B

C

D

E

Changing Polarity

Example: 2/40 =

To read settings:

Number on left of slash

is voltage,numberon

right of slash is wire

speed.“—” means

not recommended.

#199208B

Select Voltage and Wire Speed Based

on Thickness of Metal Being Welded

SETTINGS ON THIS CHART ARE STARTING

VALUES ONLY AND ARE ON 230 INPUT

LINE VOLTAGE. SEE OWNERS MANUAL

FOR MORE INFORMATION.

Wire Drive Assembly

Lead To Positive (+)

Output Terminal

Work Clamp Lead

To Negative (−)

Output Terminal

Electrode Negative (DCEN): Reverse lead

connections at terminals from that shown

for gasless flux cored wires (FCAW). Drive

assembly becomes negative.