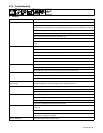

OM-478 Page 33

1000 h

Change Fuel

Filters. See

Section 8-4.

Drain Sludge

From Fuel

Tank. See

Section 8-4.

FUEL

SLUDGE

Blow Out Or

Vacuum Inside.

During Heavy

Service,

Clean Monthly.

OR

Service Welding

Generator Brushes

And Slip Rings.

Service More Often

In Dirty Conditions.*

Check

Valve

Clearance.*

1/2 in.

(13 mm)

Check Belt

Tension. See

Section 8-8.

1200 h

Service Air

Compressor.*

3000 h

Clean/Set

Injectors.*

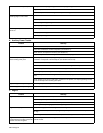

8-2. Servicing Air Cleaner

aircleaner1 4/96 – ST-153 585 / Ref. ST-184 780-C / Ref. ST-184 780-C / Ref. S-0698-B

Y Stop engine.

Y Do not run engine without air

cleaner or with dirty element.

Clean or replace element if dirty or

damaged. Replace element yearly

or after six cleanings.

1 Dust Cap

2 Baffle

3 Element

4 Plastic Fins

5 Housing

To clean air filter:

Wipe off cap and housing. Remove

cap and dump out dust. Wipe dust

from inside cap and housing with

damp cloth. Remove element and

reinstall cap.

Y Do not clean housing with air

hose.

Clean element with compressed air

only. Keep nozzle at least 1 in (25

mm) from inside of element. Max. air

pressure: 100 psi (690 kPa). Do not

remove plastic fins. Replace ele-

ment if it has holes or damaged

gaskets.

Reinstall element and cap (cap

arrows pointing up).

1235 4

Blow Inspect