OM-478 Page 38

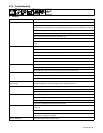

8-8. Checking And Replacing Engine Belt

Ref. ST-121 577-B / Ref. ST-184 781-A

Y Stop engine.

A V-belt drives the engine cooling

fan and alternator. To check

tightness of belt, proceed as

follows:

Remove rear panel and guard from

engine pulley.

1 Fan Pulley

2 Alternator Pulley

3 Engine Belt

Position straight edge along top of

pulleys. Pull down belt as far as it

will go, and measure distance from

belt to straight edge.

If less than 1/2 in (13 mm), belt is

okay. If not okay, adjust belt as

follows:

4 Alternator Bracket

Loosen hex nut on bracket.

5 Alternator Pivot Hex Nut

Loosen hex nut. Pivot alternator

clockwise until belt is tight. Tighten

hex nuts.

Recheck tightness of belt. Readjust

if necessary.

Replace belt if damaged or

cracked. Replace belt as follows:

Loosen hex nuts, pivot alternator

counterclockwise, and remove

belt. Install new belt, pivot alternator

clockwise, adjust tightness, and

tighten hex nuts. Recheck tight-

ness of belt after operating engine

15 minutes.

Reinstall guard and rear panel.

Tools Needed:

1/2 in, 13 mm, 17mm

1

2

3

4

5

1/2 in (13 mm)

Maximum

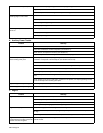

8-9. Servicing Optional Spark Arrestor

ST-157 313-A / Ref. ST-184 781-A

Y Stop engine and let cool.

1 Spark Arrestor

2 Cleanout Plug

Remove plug and remove any dirt

covering cleanout hole.

3 Exhaust Pipe

Start engine, and run at idle speed

to blow dirt out cleanout hole. If

nothing blows out of hole, briefly

cover end of exhaust pipe.

Y Stop engine and let cool.

Reinstall cleanout plug.

1

2

3

Tools Needed:

3/8 in