OM-493 Page 26

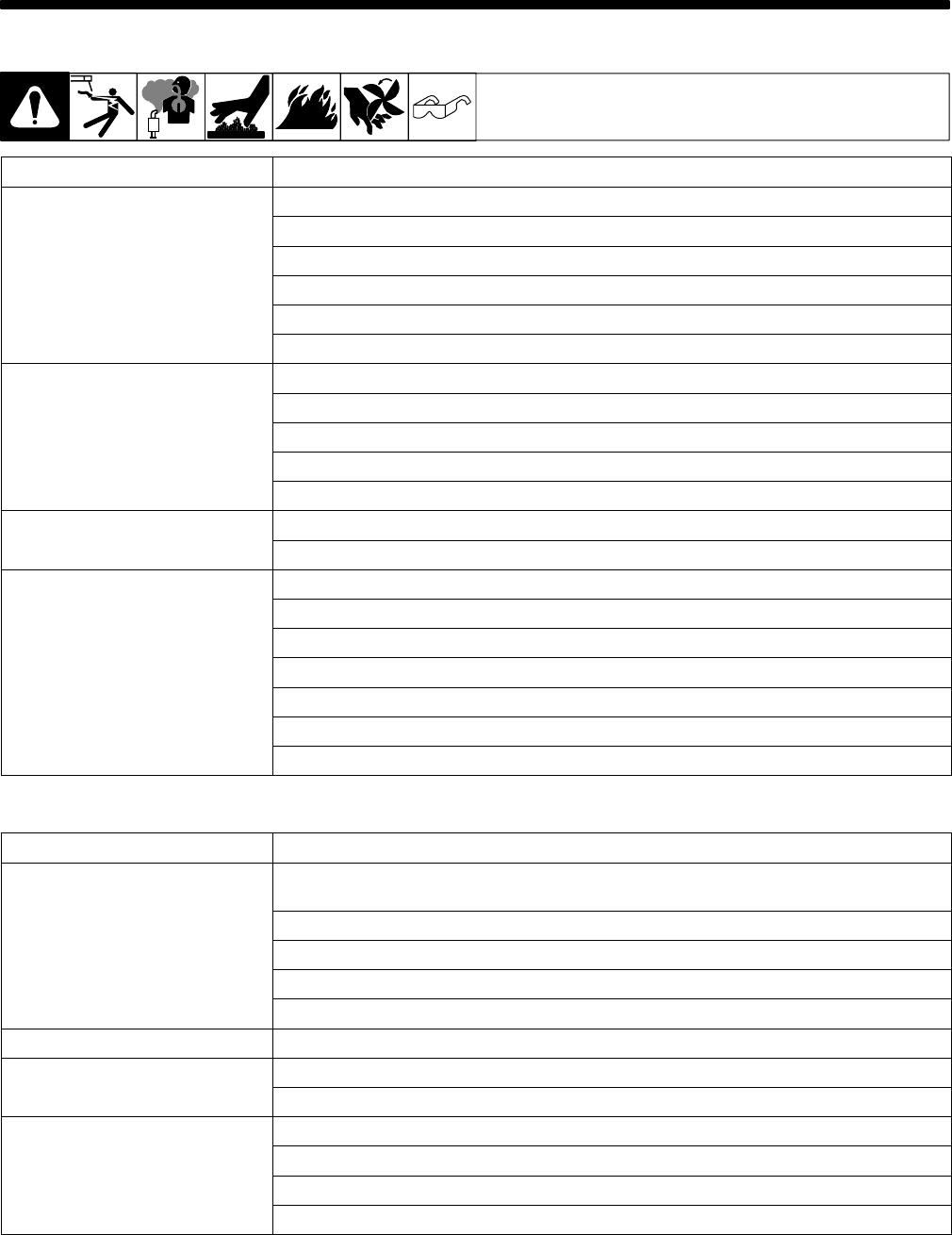

SECTION 8 – TROUBLESHOOTING

A. Welding

Trouble Remedy

No weld output. Check control settings.

Check weld connections.

Check fuse F1 and replace if open (see Section 7-4).

Be sure all equipment is disconnected from receptacles when starting unit.

Have Factory Authorized Service Agent check brushes, slip rings, and integrated rectifier SR2.

Check plug PLG6 connection.

Low weld output. Check fuse F1 and replace if open (see Section 7-4).

Check control settings.

Check engine speed, and adjust if necessary (see Section 7-6).

Service air cleaner according to engine manual.

Have Factory Authorized Service Agent check brushes and slip rings.

High weld output. Check control settings.

Check engine speed, and adjust if necessary (see Section 7-6).

Erratic weld output. Check control settings.

Tighten and clean connections to electrode and workpiece.

Use dry, properly-stored electrodes for Stick and TIG welding.

Remove excessive coils from weld cables.

Clean and tighten connections both inside and outside welding generator.

Check engine speed, and adjust if necessary (see Section 7-6).

Have Factory Authorized Service Agent check brushes and slip rings.

B. Auxiliary Power

Trouble Remedy

No output at auxiliary power

receptacles.

Reset circuit breakers (see Section 6-1).

Press optional GFCI receptacle Reset button (see Section 6-2).

Check fuse F1 and replace if open (see Section 7-4).

Check plug PLG6 connection.

Have Factory Authorized Service Agent check brushes, slip rings, and integrated rectifier SR2.

High power output. Check engine speed, and adjust if necessary (see Section 7-6).

Low power output. Check fuse F1 and replace if open (see Section 7-4).

Increase Fine Adjust control R1 setting.

Erratic power output. Check fuel level.

Check engine speed, and adjust if necessary (see Section 7-6).

Check receptacle wiring and connections.

Have Factory Authorized Service Agent check brushes and slip rings.