OM-355 Page 16

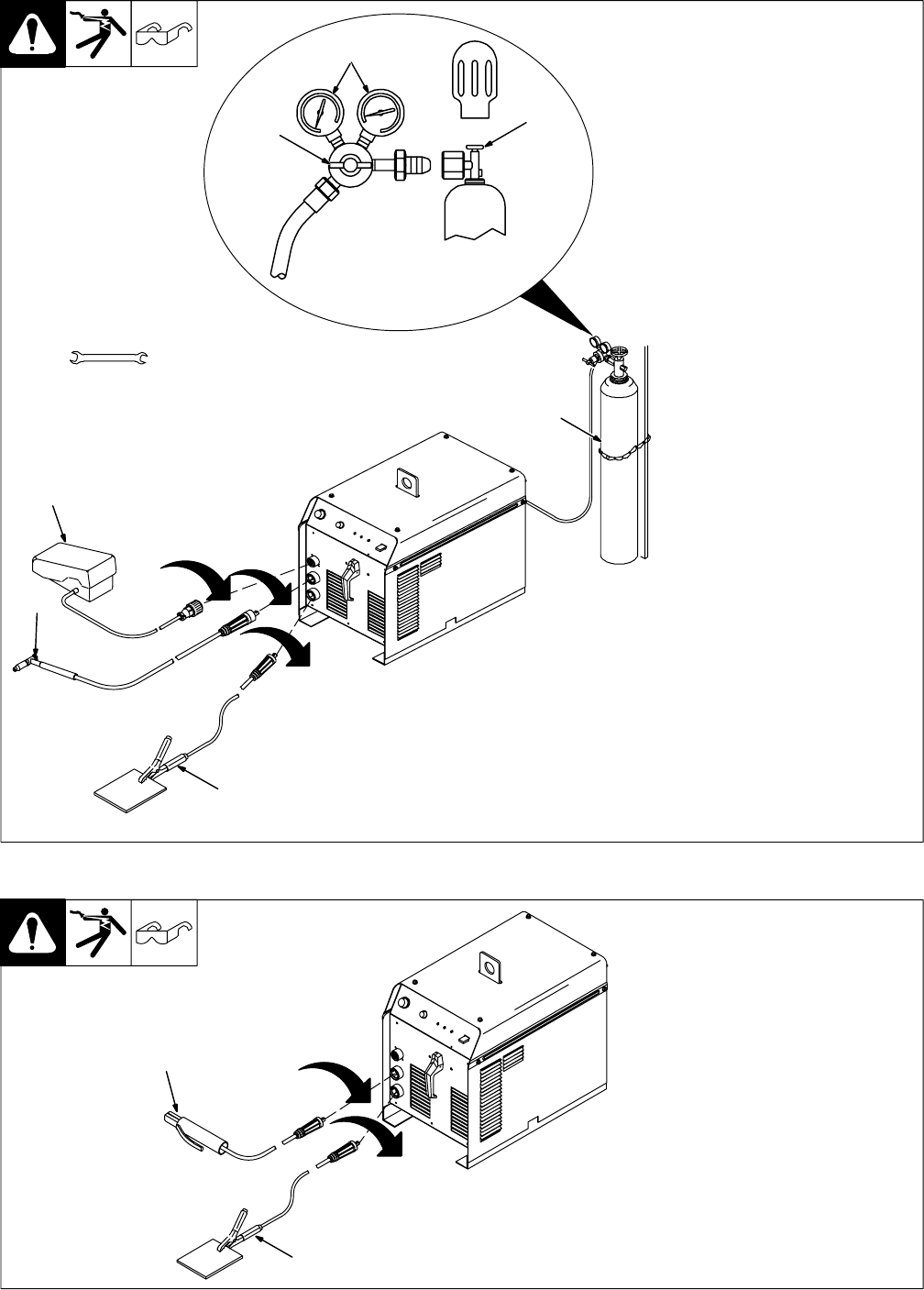

3-4. Typical TIG Connections

ST-802 238

1 Remote Foot Control

A customer supplied remote finger-

tip control may also be used.

2 Torch

3 Work Clamp

Connect remote control, torch, and

work clamp to receptacles as

shown.

4 Cylinder

Chain or secure cylinder to running

gear, wall, or other stationary

support.

5 Cylinder Valve

Open valve slightly so gas flow

blows dirt from valve. Close valve.

6 Regulator/Flow Gauge

Install so face is vertical.

7 Flow Adjust

Typical flow rate is 20 cfh (cubic feet

per hour) (9.4 L/min).

NOTE: After activating remote con-

trol, 0.3 seconds of gas preflow will

begin.

Application:

Preflow is used to purge the imme-

diate weld area of atmosphere.

Preflow also aids in consistent arc

starting.

NOTE: When remote control is

released, gas continues to flow for

18 seconds

Application:

Postflow is required to cool tung-

sten and weld, and to prevent con-

tamination of tungsten and weld. In-

crease postflow time if tungsten or

weld are dark in appearance.

NOTE: Both preflow and postflow

are preset and are not adjustable.

NOTE: When AC welding, the bal-

ance control is preset at 60% elec-

trode negative (EN), and 40% elec-

trode positive (EP).

5

6

7

Tools Needed:

5/8, 1-1/8 in

4

1

2

3

3-5. Typical Stick Connections

ST-802 238

1 Electrode Holder

2 Work Clamp

Connect electrode holder and work

clamp to receptacles as shown.

1

2