37

4.10 MOTOR LUBRICATION (Continued)

Grease relief along shaft can occur, precluding necessity

of removing this plug if inaccessible.The inlet grease gun

fittings and outlet plugs (or spring-loaded reliefs) are

located at each end of the motor housing. The drive end

reliefs protrude out the circumference of the lower portion

of the end bell near a flange bolt. The drive end outlet

plugs are located just behind the flange in the air intake

area at about the 5 or 6 o’clock position.

1) Free drain hole of any hard grease (use piece of wire

if necessary).

2) Use a hand lever type grease gun. Determine in

advance the quantity of grease delivered with each

stroke of the lever. A graduated cylinder showing

cubic centimeters (cc) may be used, or a 35mm film

canister can give a close approximation for 2 cubic

inches when filled.

3) Add the recommended volume of the recommended

lubricant. Do not expect grease to appear at the

outlet, but if it does, discontinue greasing at

once.

4) Run motor for about 30 minutes before replacing out-

let plugs or reliefs. BE SURE TO SHUT MOTOR

DOWN, DISCONNECT POWER, LOCK OUT AND

TAG, AND REPLACE THESE DRAIN FITTINGS TO

PRECLUDE LOSS OF NEW GREASE AND

ENTRANCE OF CONTAMINANTS!

Recommended Motor Grease

60 Hz motors require:

Mobilith SHC 220 (39218193)

Use the grease as indicated on a special grease

information nameplate on the motor. Use of alternative

greases can result in shortened motor life due to

incompatibility of greases. If there is not a grease

nameplate on the motor use:

Chevron Black Pearl #2 (39204292)

(Preferred)

Chevron SRI 2 (39161641)

50 Hz motors require

Esso Unirex N3 (92844729)

MOTOR BEARING MAINTENANCE

(STORED UNITS)

To ensure that complete contact is maintained between

the motor bearings and the bearing grease on units to be

placed in storage for extended intervals, the following

motor maintenance procedure should be adhered to:

1) Prior to placing a unit in storage, rotate the motor

several revolutions by hand in the proper direction of

rotation.

2) Thereafter, rotate the motor as described in Step 1 at

three month intervals until such time as the unit is

placed in service.

3) If the storage time is to exceed a total of nine (9)

months duration, the compressor must be ordered

with long term storage option.

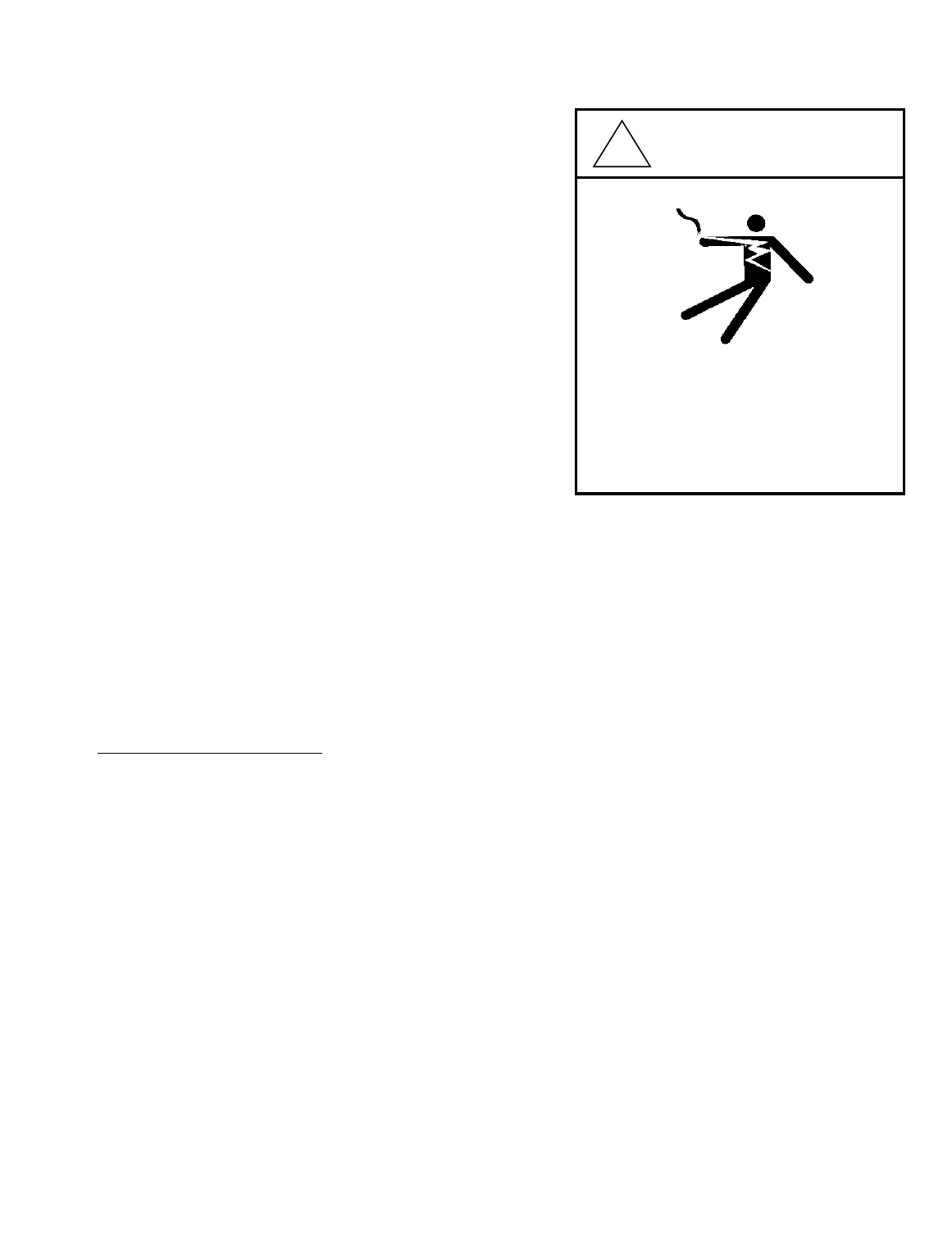

WARNING

!

Hazardous voltage. Can cause

severe injury or death.

Disconnect power before servicing.

Lockout/Tagout machine.